Warranty:Other

Place of Origin: Zhejiang, China

Brand Name:SDM

Model Number:Customization

Selling Units:Single item

Single package size:15X10X15 cm

Single gross weight: 1.500 kg

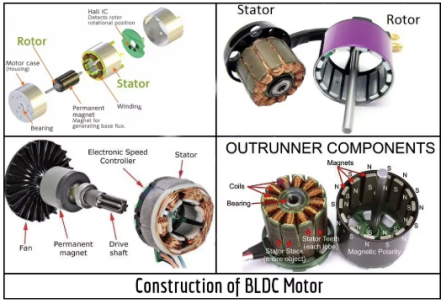

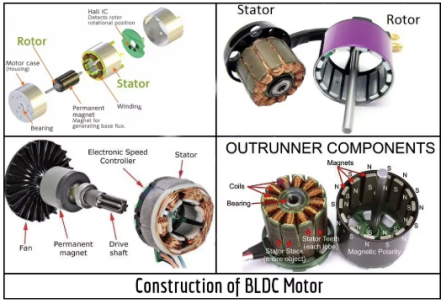

The motor stator, a pivotal component in electric motors, plays a crucial role in the conversion of electrical energy into mechanical energy. Its design and features significantly impact the performance, efficiency, and reliability of the motor. Here's an overview of some key features of a motor stator:

The stator, typically stationary within the motor housing, is constructed from laminated steel sheets to minimize eddy current losses and improve thermal conductivity. These sheets are stacked and insulated from each other, creating a structure that is both sturdy and efficient.

Core Geometry: The stator core features precisely designed slots that house the stator windings. The shape and number of slots, along with their arrangement, are optimized for specific motor applications. For instance, radial slots offer simpler construction but may have higher harmonic content, while skewed slots help reduce cogging torque and noise.

Windings: The stator windings, typically made of copper or aluminum, are wound around the stator teeth. They form the electromagnetic circuit that interacts with the rotating magnetic field generated by the rotor, creating torque. The number of turns, wire gauge, and insulation material are carefully selected to achieve the desired motor characteristics.

Cooling System: Effective cooling is essential for maintaining optimal stator temperature, especially in high-power applications. Some stator designs incorporate cooling fins, channels, or even liquid cooling systems to dissipate heat generated during operation.

Insulation: High-quality insulation ensures electrical isolation between the windings and the stator core, preventing short circuits and ensuring safe operation. Modern insulation materials are designed to withstand high temperatures and mechanical stresses.

Durability: The stator must withstand the mechanical and thermal stresses associated with continuous operation. Its construction materials and design are chosen to ensure long-term durability and reliability.

Customizability: Depending on the application, stator features can be customized to meet specific performance requirements. This includes adjustments to the number of poles, winding configuration, and cooling system to optimize the motor's efficiency, torque, and speed range.

In summary, the motor stator's intricate design and features are tailored to achieve optimal performance and reliability. Its core geometry, windings, cooling system, insulation, durability, and customizability contribute significantly to the overall performance of the electric motor.