High-speed motor rotor refer to AC and DC motors with high speed (usually at 10,000 RPM and above). Its electronic characteristics are mainly reflected in the following aspects.

First, high speed and power density

High-speed motor has a very high speed, the speed range is usually 10000~60000 RPM, much higher than the ordinary motor.

Due to the increase in speed, the power density of high-speed motors is also relatively high, small size, and light weight, which makes high-speed motors have significant advantages in occasions where high power output is required.

Second, high efficiency and low energy consumption

High-speed motor design pays more attention to reduce internal wear, maximize the use of electric energy, improve efficiency, etc., so its operating efficiency is usually high, the efficiency of the whole machine can reach more than 96%.

Compared with traditional motors, high-speed motors consume less energy at high speed conditions, which is conducive to energy saving and emission reduction.

3. Fast dynamic response

High speed motor has small moment of inertia, so it has fast dynamic response speed. This makes high-speed motors more adaptable in situations where quick start and stop or frequent speed adjustments are required.

Fourth, high control accuracy

High speed motors are often precisely controlled and regulated using frequency converters based on power semiconductor devices so that the motor speed can be easily adjusted as needed.

With the development of technology, the control technology of high-speed motors is also improving, including advanced control strategies such as vector control and direct torque control, so that high-speed motors can achieve accurate and efficient operation under various complex conditions.

5. High reliability and low maintenance cost

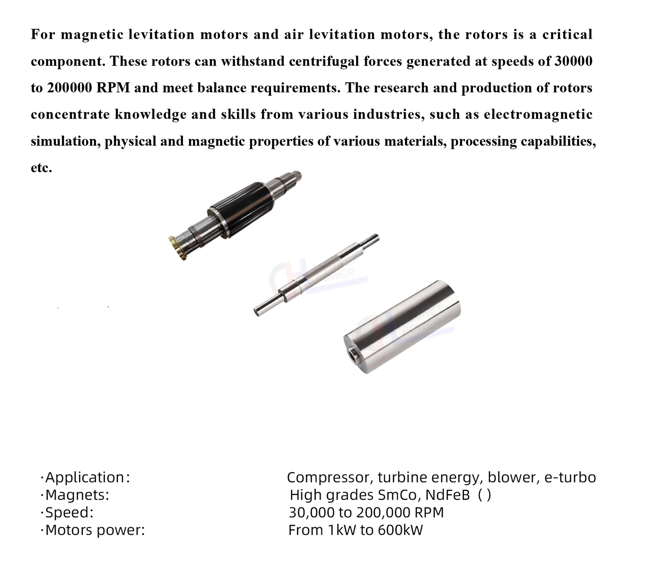

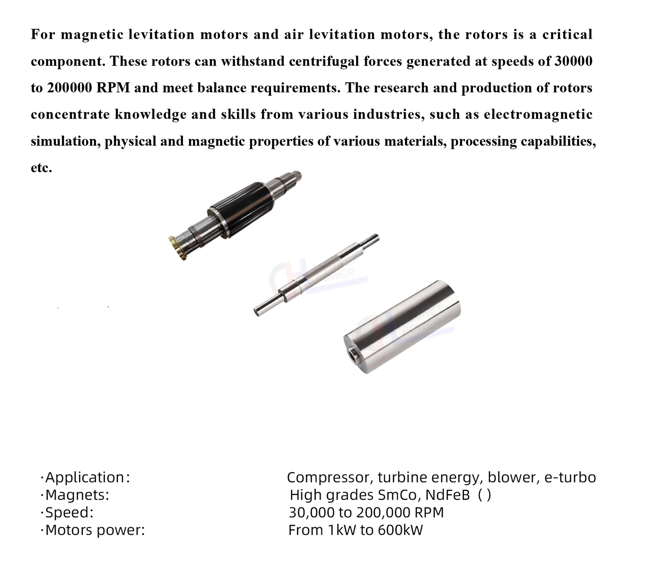

In the design and manufacturing process of high-speed motor, the key issues such as material strength, thermal stability, dynamic balance and bearing life are fully considered to ensure the stability and reliability of the motor under high-speed operation.

Some high-speed motors are supported by magnetic bearings, no contact, no friction, almost no maintenance, thus reducing maintenance costs.

6. Low noise

The high-speed motor uses more advanced bearing and cooling technology, as well as reasonable lubrication methods, effectively suppressing vibration and noise.

Compared with traditional motors, high-speed motors generate less noise during operation, which is conducive to improving the working environment.

In summary, high-speed motors have many significant electronic characteristics, which make high-speed motors widely used in modern industry, such as centrifugal air conditioners and chillers, centrifugal air compressors, high-speed turbines and new energy vehicles.