Eddy current sensors, also known as eddy current displacement sensors or inductive sensors, are devices that utilize the principles of electromagnetic induction to detect and measure physical parameters such as displacement, position, velocity, and thickness. These sensors operate by generating an alternating magnetic field that induces eddy currents in a nearby conductive target. The interactions between these eddy currents and the sensor's magnetic field provide the basis for accurate and reliable measurements.

Key Features and Advantages

High Accuracy and Reliability:

Our Eddy Current Sensors are designed for high accuracy, offering precise measurements in industrial environments where traditional contact-based sensors would fail. The sensors can operate effectively in temperatures ranging from -40°C to +150°C and are capable of providing results with an accuracy of up to ±0.5%. The sensors use advanced harmonic control and material performance optimization to ensure stability and reliability over time.

Non-contact Measurement:

Eddy Current Sensors offer a non-invasive way to measure displacement, thickness, and other material properties, making them ideal for delicate or high-speed operations where traditional contact-based sensors might damage the material or affect performance.

Wide Application Range:

These sensors are widely used in industries such as automotive, aerospace, manufacturing, and robotics, particularly in situations that require the detection of small gaps, wear and tear, or surface defects in metals. They are also used for monitoring motor rotor positions, detecting vibrations, and evaluating material thickness without making physical contact.

Structural Design Optimization

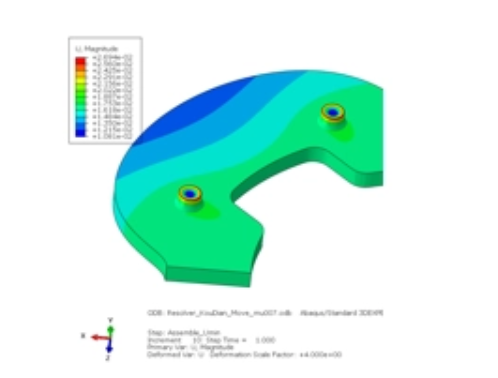

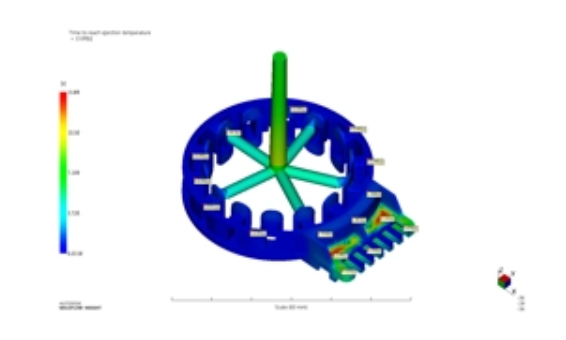

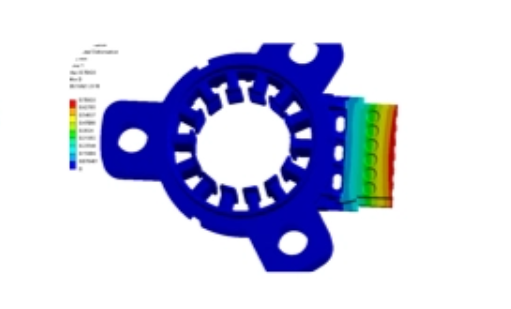

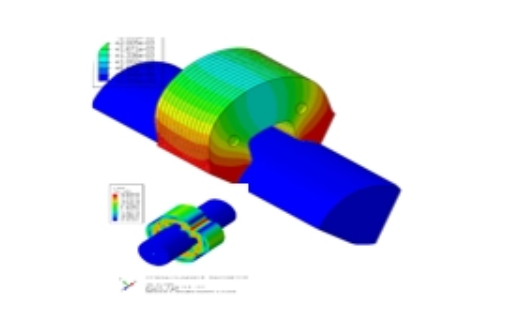

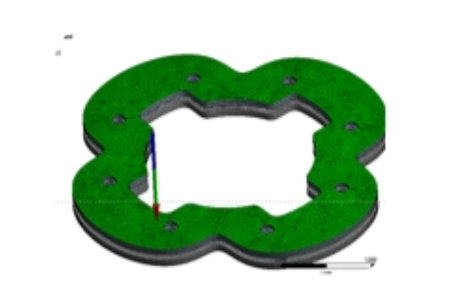

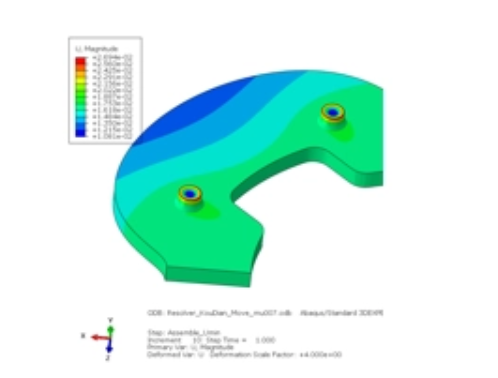

Our Eddy Current Sensors are designed with precision and durability in mind. The structural strength is optimized through thorough risk analysis of structural stress, ensuring a solid, long-lasting design. The sensor's construction is carefully modeled and tested using various simulation techniques, such as:

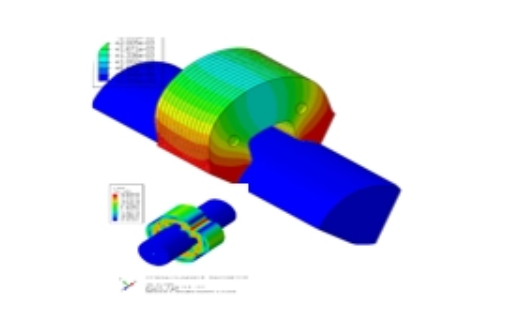

Simulation of the Force-Bearing Strength: Ensuring the entire structure can withstand external forces without failure.

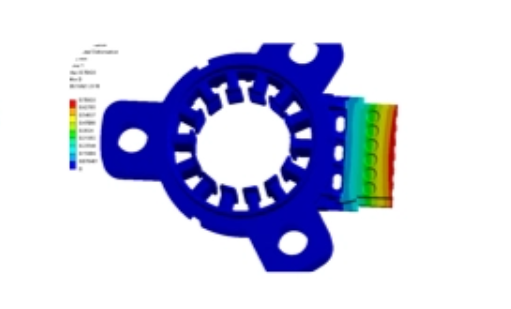

Mold-flow Analysis: This ensures that plastic components are optimized for performance and stability under different manufacturing conditions.

Analysis of the Pull-off Force and Deformation: Analyzing the forces that could affect the interlock mechanism and identifying potential failure points to avoid any operational disruptions.

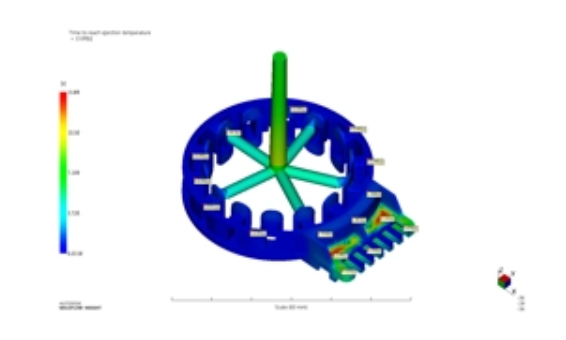

Mold-flow Analysis of plastic frame

Simulation of the Force-Bearing Strength

Analysis of rotor assembly

Analysis of the Pull-off Force of interlock

Analysis of deforming of interlock

Performance Parameters

| Specification | Details |

| Input Power | 5V DC |

| Power | 0.07W |

| Output | 2V DC (Sin/Cos) |

| Pole Pairs | Corresponding to the number of pole pairs of motor rotor |

| Working Temperature | -40°C to +150°C |

| Decode | Exclusive chip is not essential |

| Accuracy | 0.1° ~ 0.5° |

| Max Working RPM | 200k RPM |

| Reliability | With chips, limited temperature adaptation |

| Production | Simple process, Main structure combined with PCB |

| Use | Easy to use, high anti-interference capability |

| Water-Cooled Scheme | Lower cost without casing |

| Series | 59, 89 |

The plug-in structure of the connector is flexible and convenient for installation, and the structure is simple and reliable.

The glue-potting scheme for the oil-cooled casing has a reliable structure.

The water-cooled scheme without a casing has a lower cost.

Customized Solutions

Our Eddy Current Sensors are not only designed to meet standard industry needs but also to provide custom solutions tailored to the most specific requirements. By working closely with clients, we can offer various options for input voltage, output signal types, and construction designs. Whether you're looking for enhanced corrosion resistance, high-temperature tolerance, or a particular form factor, we are equipped to meet your demands.

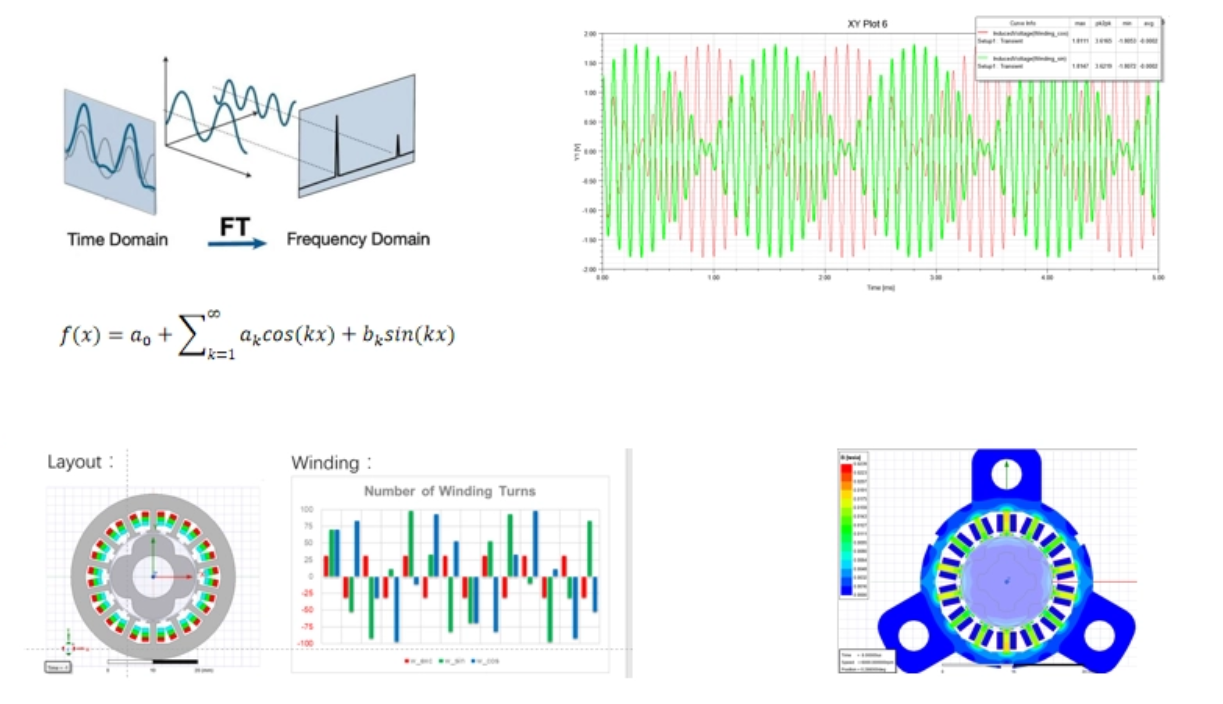

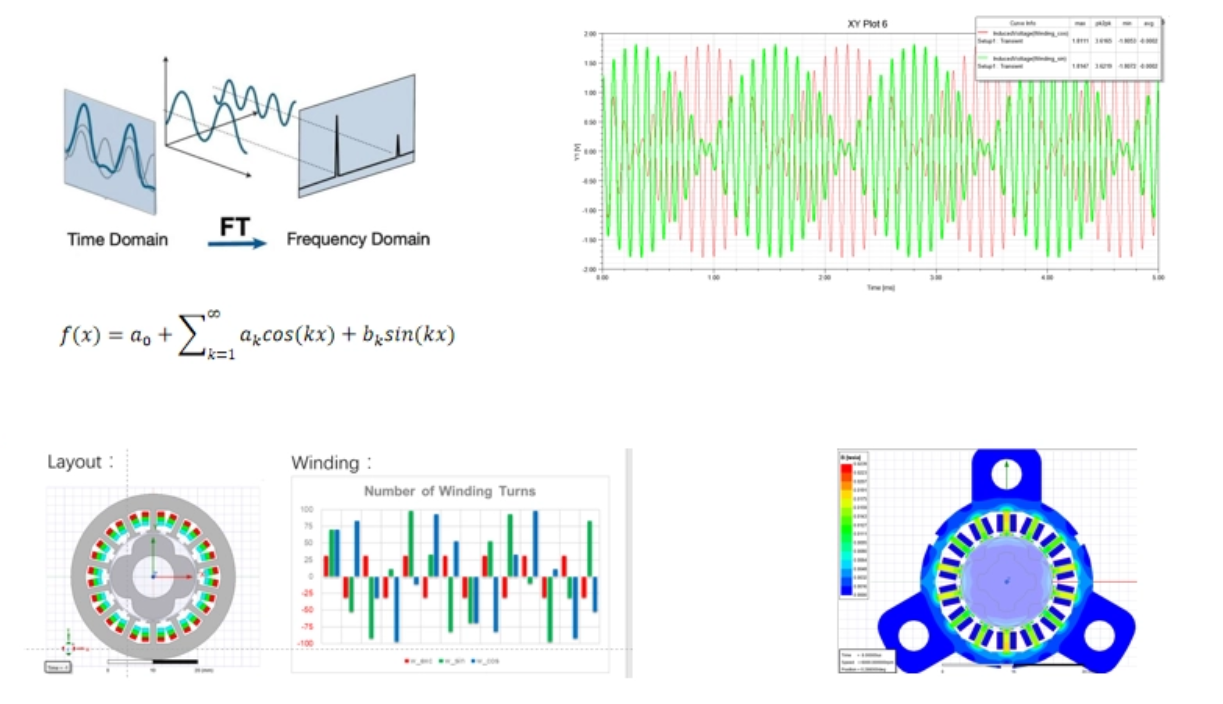

Performance Design

Why Choose SDM Magnetics as Your Eddy Current Sensors Manufacturer?

At SDM Magnetics, we are a trusted Eddy Current Sensors Manufacturer known for delivering high-quality, reliable, and innovative sensor solutions. Here’s why you should partner with us:

Expertise and Experience

With years of experience in the sensor industry, we specialize in designing and manufacturing Eddy Current Sensors that meet the highest standards of precision and durability. Our team’s deep technical knowledge ensures that every product we produce is optimized for performance and reliability.

Customization for Your Needs

As a leading Eddy Current Sensors Manufacturer, we understand that every application is unique. We offer highly customizable sensors tailored to meet the specific requirements of your project, whether it's for high-temperature environments, precision measurements, or specialized configurations.

Cutting-Edge Technology

We utilize the latest technology in our design and production processes, ensuring that our Eddy Current Sensors deliver exceptional accuracy and efficiency. With advanced features such as harmonic control, magnetic field distribution simulation, and comprehensive performance testing, our sensors are built to excel in demanding environments.

Superior Quality and Reliability

At SDM Magnetics, quality is our top priority. Our Eddy Current Sensors undergo rigorous quality control and testing to guarantee that they perform flawlessly under all conditions. Whether it's for automotive, aerospace, industrial, or robotics applications, our sensors are built to last and deliver consistent results.

Customer-Focused Service

We believe in building long-term relationships with our clients by providing exceptional customer support and post-sale services. From the initial consultation to after-sales support, our team is here to guide you and ensure your success with our products.

Global Reach

As an Eddy Current Sensors Manufacturer, we serve customers worldwide, providing reliable sensors for industries ranging from manufacturing to automation, robotics, and more. No matter where you are, SDM Magnetics can deliver the best sensor solutions.