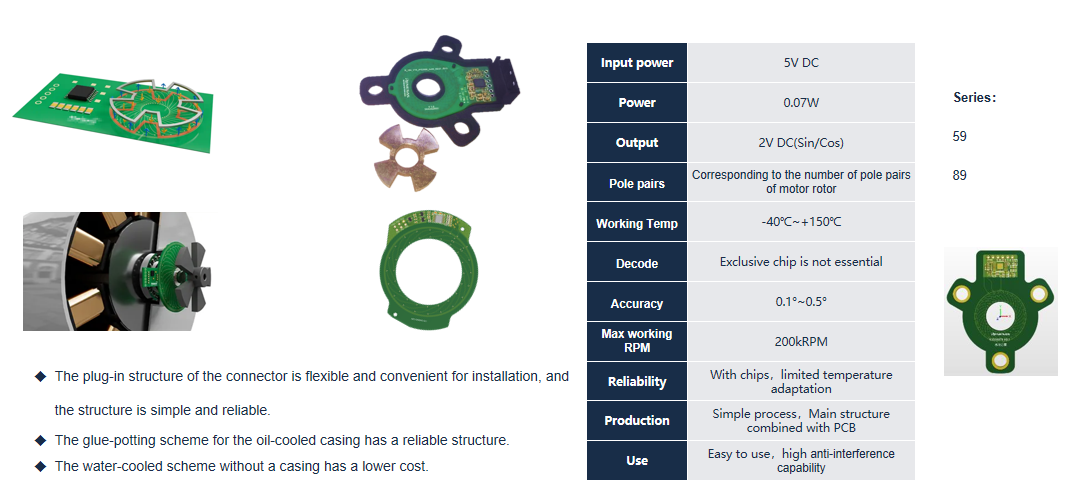

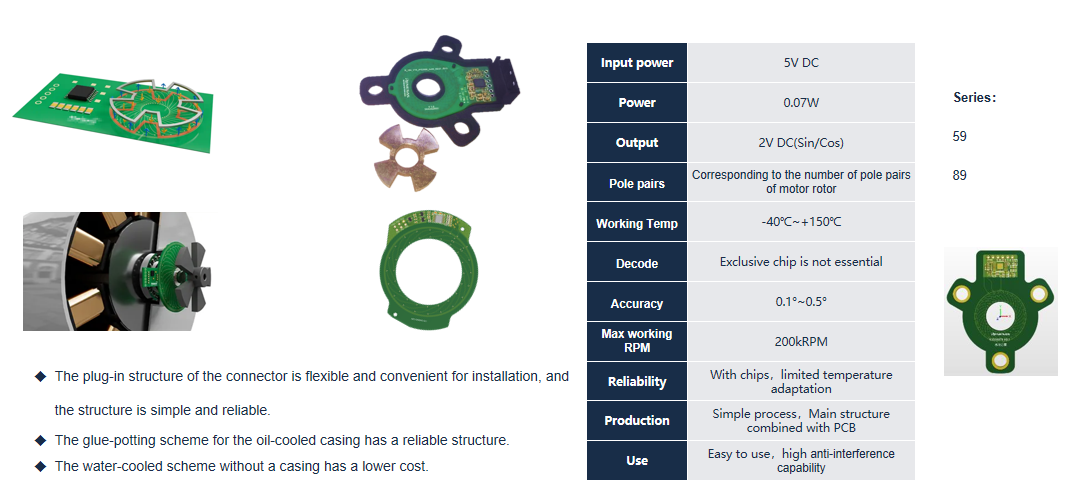

The characteristics of Eddy current Resolvers (Eddy current sensors) are significant and diverse. It has the characteristics of non-contact measurement, and can realize the displacement measurement with high linearity and high resolution. At the same time, the eddy current sensor has high sensitivity, strong anti-interference ability, and can quickly respond to the change of the measured object. In addition, it is not affected by media such as oil and water, and has good long-term reliability and wide measurement range. It has been widely used in on-line monitoring and fault diagnosis of large rotating machinery.

Eddy current resolver (Eddy current sensor) has a wide range of applications, mainly including the following aspects:

Mechanical manufacturing: Eddy current sensors are used extensively in the machine tool industry and automotive manufacturing to measure and monitor parameters such as displacement, vibration and rotational speed of mechanical components.

Power industry: Used for long-term real-time monitoring of shaft displacement, shaft vibration, shaft speed and other parameters of large rotating machinery (such as steam turbines, water turbines, generators, etc.) to ensure the safe operation of equipment.

Petrochemical: In the petrochemical industry, eddy current sensors can be used to monitor the operating status of various equipment to detect and prevent potential failures in time.

Aerospace: In the aerospace sector, the high accuracy and non-contact measurement characteristics of eddy current sensors make them ideal for monitoring critical components such as aircraft engines.

Non-destructive testing: Eddy current sensors can be used to detect surface and near-surface defects of metal materials, such as cracks, corrosion, etc.

In addition, eddy current sensors also play an important role in metallurgy, transportation, military and other fields.