SDM Coreless Motor

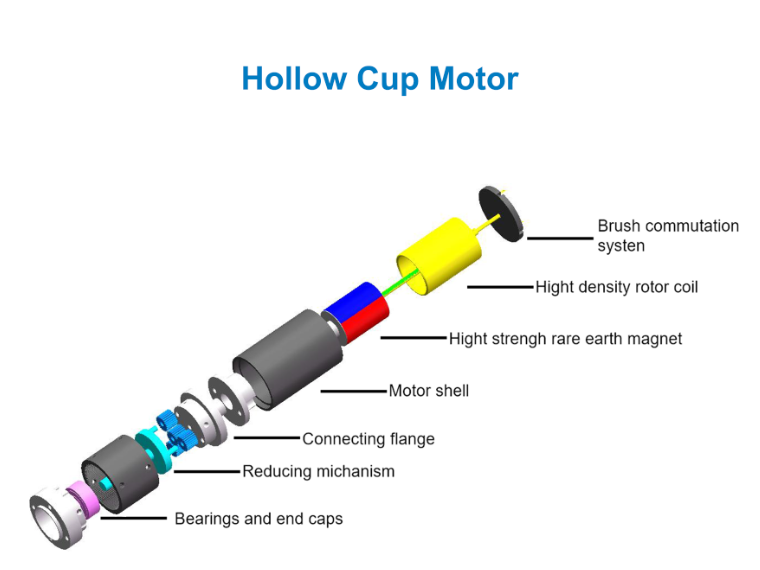

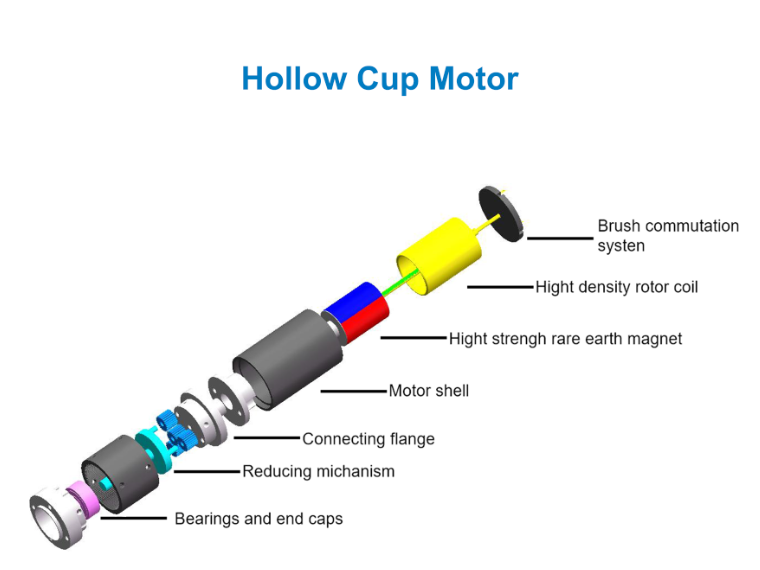

Coreless motor is a new type of micro motor which also known as hollow cup motor. coreless motor utilizes slotless and coreless coil as the armature winding which pierced iron core structure of traditional motor, then significantly reduce weight and momen of inertia and fundamentally eliminate the eddy current loss of iron core, therefore, energy loss of motor during the running process will be decreased.

The hollow cup motor, also known as the moving-coil machine, is a type of low-inertia DC servo motor widely applied across various industries due to its high efficiency, reliability, low noise, and low vibration.

In the field of robotics, hollow cup motors are utilized in industrial robots, service robots, and specialty robots for precise speed and position control, enabling high-accuracy movements. They are also essential in driving precision instruments such as numerical control machines, laser cutters, and optical devices, ensuring stability and accuracy during high-speed operations.

In the automotive industry, hollow cup motors are found in electric and hybrid vehicles, enhancing driving range and comfort. They power various automotive auxiliaries like electric seats, sunroofs, and mirrors, improving overall vehicle safety and comfort.

Furthermore, hollow cup motors are used in medical imaging equipment and surgical robots, contributing to the clarity of medical images and the safety of surgical procedures. In household appliances, they are commonly found in vacuum cleaners, fans, and washing machines, enhancing cleaning performance, air circulation, and laundry efficiency.

In summary, hollow cup motors play a crucial role in industrial automation, aerospace, automotive, medical equipment, household appliances, and consumer electronics.