#### Introduction

The rapid advancement of artificial intelligence (AI) is reshaping industries and redefining the boundaries of technology. Among the various components that power AI-driven devices and systems, micro motors, particularly hollow cup motors, play a crucial role. These motors, known for their high efficiency, precision, and compact size, are becoming increasingly vital in various AI applications. This article delves into the application prospects and development trends of hollow cup motors in the field of artificial intelligence.

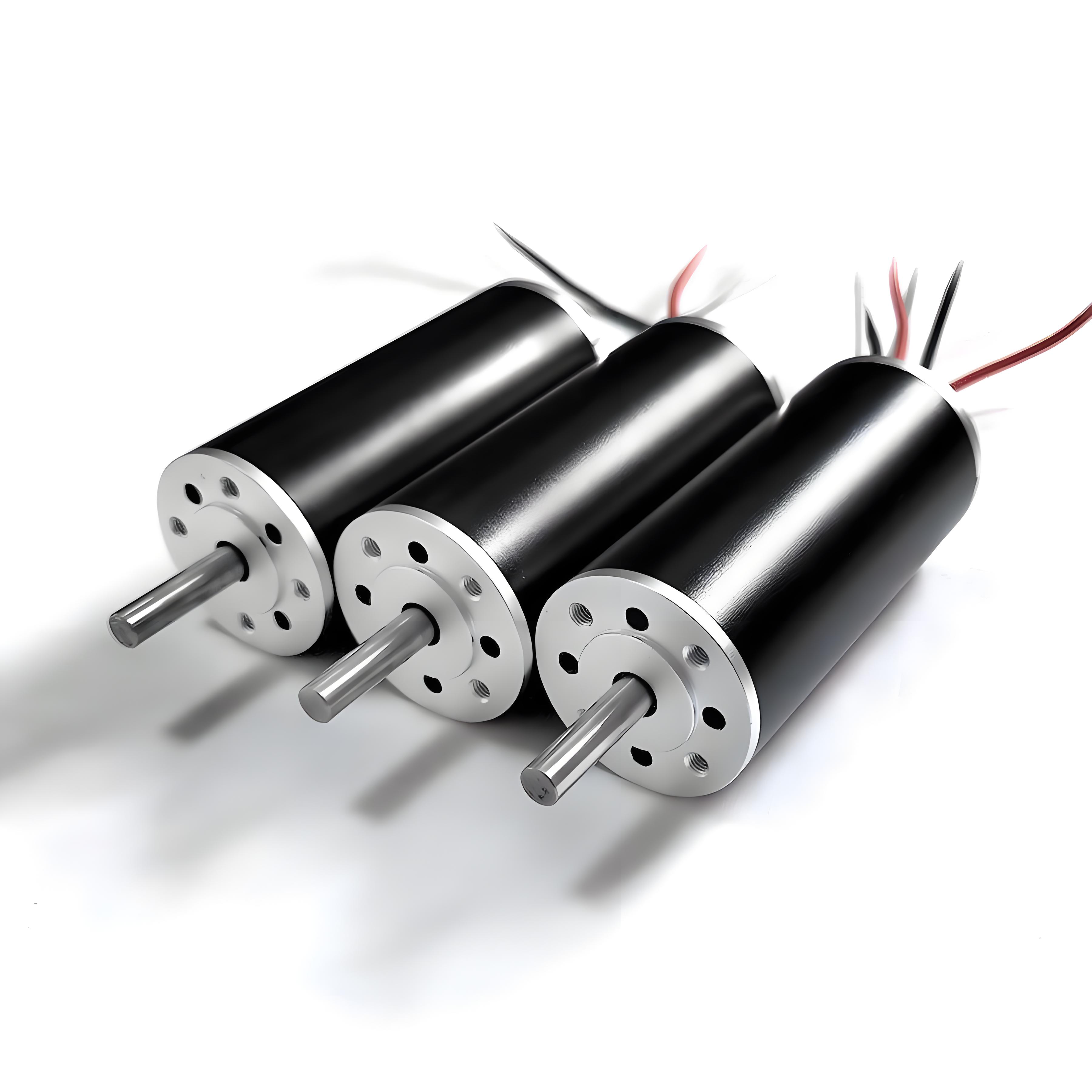

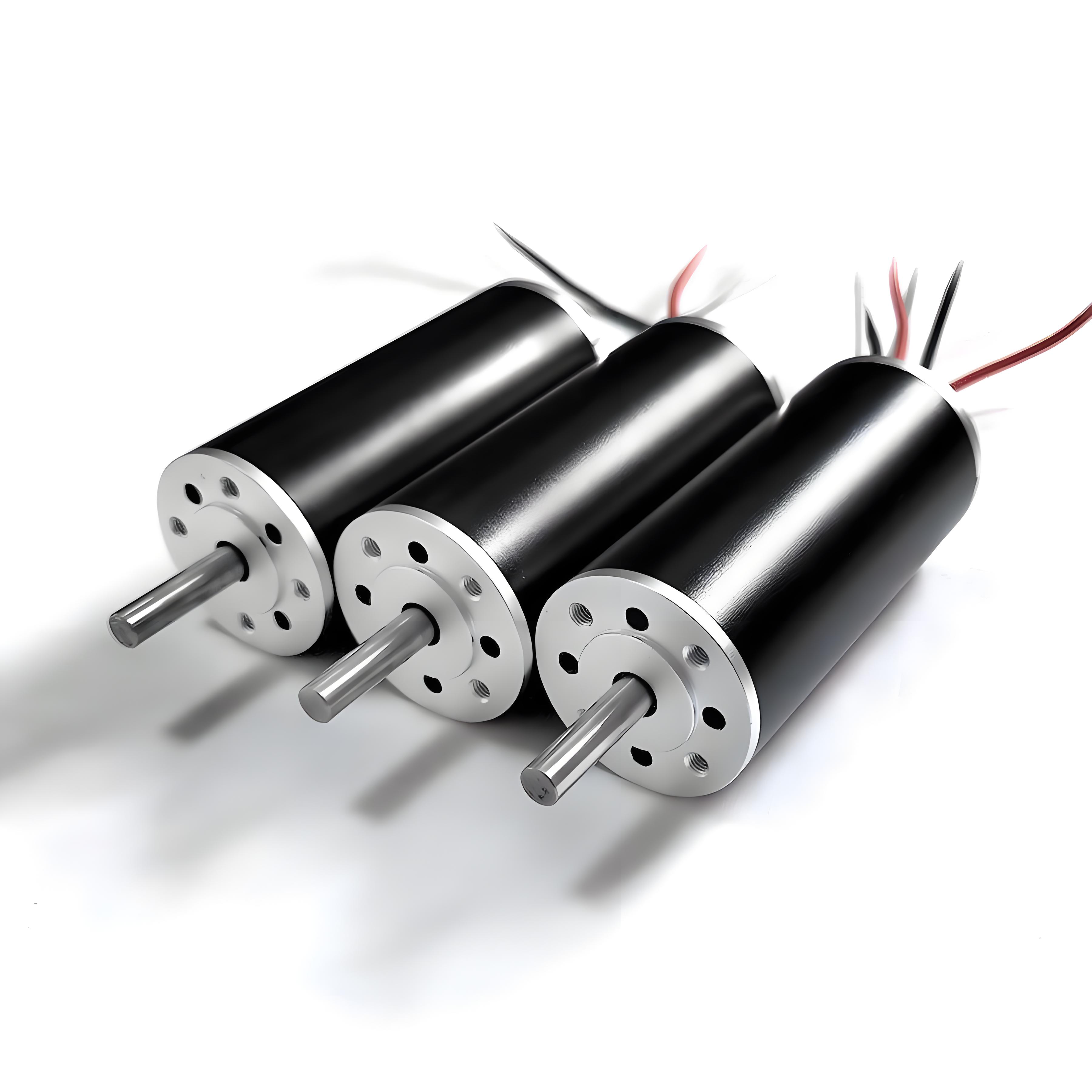

#### Understanding Hollow Cup Motors

Hollow cup motors, also known as coreless motors, are a type of direct current (DC) motor distinguished by their rotor design. Unlike traditional motors that have a solid iron core, hollow cup motors feature a rotor made from a winding that forms a hollow cylindrical shape. This design reduces the inertia of the rotor, enabling rapid acceleration and deceleration, higher efficiency, and smoother operation. These characteristics make hollow cup motors particularly suitable for applications requiring precise control and fast response times.

#### Application Prospects in AI

##### Robotics

One of the most significant applications of hollow cup motors in AI is in robotics. Both industrial and service robots benefit from the precision and efficiency of these motors. In industrial robotics, hollow cup motors are used in robotic arms for tasks that demand high precision, such as assembly, welding, and painting. Their ability to provide smooth and accurate movement ensures high-quality performance in these applications.

In service robotics, hollow cup motors power robots designed for healthcare, hospitality, and domestic assistance. For instance, in surgical robots, these motors enable delicate and precise movements, enhancing the capabilities of surgeons. In domestic robots, hollow cup motors drive small yet powerful devices like vacuum cleaners and window cleaning robots, ensuring effective operation in compact and complex environments.

##### Drones and Unmanned Vehicles

The use of hollow cup motors extends to drones and unmanned vehicles, both of which are integral to AI-driven applications. Drones equipped with hollow cup motors benefit from improved flight stability and maneuverability, essential for applications such as aerial photography, surveillance, and delivery services. The lightweight and efficient nature of these motors helps extend flight times and enhance payload capacity.

Unmanned ground vehicles (UGVs) and underwater vehicles (UUVs) also leverage hollow cup motors for propulsion and control. In UGVs, these motors facilitate precise navigation and obstacle avoidance, crucial for tasks such as search and rescue, exploration, and logistics. UUVs, used for underwater inspection and exploration, benefit from the compact size and reliability of hollow cup motors, allowing them to operate efficiently in challenging underwater environments.

##### Precision Instruments and Actuators

Hollow cup motors find extensive applications in precision instruments and actuators used in AI-driven systems. In laboratory automation, these motors power various instruments, including pipettes, centrifuges, and spectrometers, ensuring accurate and efficient operation. In the field of optics, hollow cup motors enable precise positioning and adjustment of lenses and mirrors in devices such as microscopes and cameras.

Actuators powered by hollow cup motors are also crucial in AI-driven automation systems. These actuators are used in applications ranging from precision manufacturing to smart home devices, where they enable fine control of movements and adjustments. For instance, in smart thermostats and blinds, hollow cup motor actuators ensure precise and quiet operation, enhancing user experience and energy efficiency.

#### Development Trends

##### Miniaturization and Integration

One of the key development trends in hollow cup motors is miniaturization and integration. As AI devices become smaller and more compact, the demand for miniaturized motors that can fit into tight spaces without compromising performance is growing. Advances in materials and manufacturing techniques are enabling the production of smaller yet powerful hollow cup motors, opening new possibilities for their application in wearable devices, medical implants, and compact robotics.

Integration of hollow cup motors with sensors and control electronics is another trend shaping their development. By embedding sensors and control circuits within the motor assembly, manufacturers are creating smarter motors capable of self-monitoring and adaptive control. This integration enhances the performance and reliability of AI-driven systems, making them more efficient and responsive.

##### Increased Efficiency and Sustainability

Efficiency and sustainability are becoming paramount in the development of hollow cup motors. Manufacturers are focusing on improving the efficiency of these motors to reduce energy consumption and extend the operational life of AI devices. Innovations such as advanced winding techniques, improved magnetic materials, and optimized motor designs are contributing to higher efficiency and reduced energy losses.

Sustainability is also driving the development of eco-friendly hollow cup motors. The use of recyclable materials, environmentally friendly manufacturing processes, and designs that facilitate easy disassembly and recycling are becoming more prevalent. These efforts align with the broader trend towards sustainable and responsible technology development, ensuring that hollow cup motors contribute to a greener future.

##### Advanced Control Techniques

The integration of advanced control techniques is enhancing the capabilities of hollow cup motors in AI applications. Techniques such as field-oriented control (FOC), model predictive control (MPC), and machine learning-based control algorithms are being employed to achieve precise and adaptive motor control. These techniques enable hollow cup motors to respond dynamically to changing conditions, improving the performance and reliability of AI-driven systems.

Machine learning, in particular, is playing a significant role in the evolution of motor control. By leveraging data from sensors and historical performance, machine learning algorithms can optimize motor operation, predict maintenance needs, and enhance overall system performance. This synergy between AI and motor control is driving the development of more intelligent and efficient hollow cup motor applications.

#### Conclusion

The application prospects and development trends of hollow cup motors in the field of artificial intelligence are both promising and dynamic. As AI continues to advance, the demand for precise, efficient, and compact motor solutions will grow, driving innovation in hollow cup motor technology. With ongoing advancements in miniaturization, efficiency, sustainability, and control techniques, hollow cup motors are poised to play an increasingly vital role in the AI-driven future, powering a wide range of applications from robotics to precision instruments and beyond.