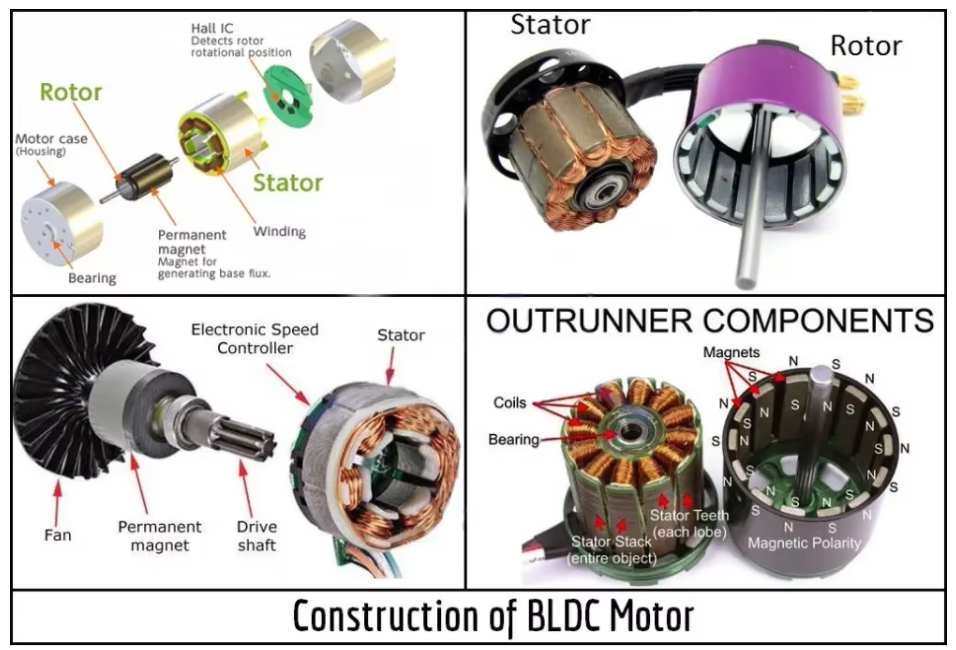

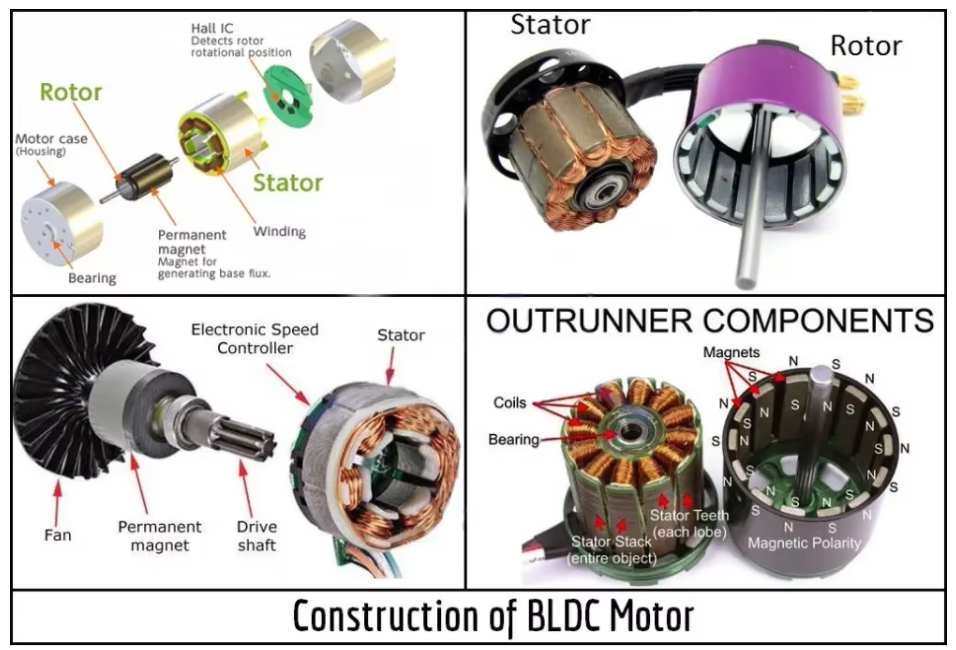

The motor stator is a vital component that determines the performance of an electric motor. Its key performance characteristics include.

Efficiency: The stator's design, including the choice of materials and winding configuration, significantly impacts the motor's efficiency. A well-designed stator minimizes energy losses, such as eddy current losses and copper losses, resulting in higher overall efficiency.

Torque Capability: The interaction between the stator's windings and the rotating magnetic field of the rotor generates torque. The stator's configuration, including the number of poles and winding layout, determines the motor's torque output and its ability to drive loads.

Thermal Management: Effective cooling mechanisms within the stator help maintain optimal operating temperatures, preventing overheating and ensuring reliable performance even under heavy loads. This enhances the motor's durability and longevity.

Noise and Vibration: The stator's design can also influence the motor's acoustic performance. By optimizing slot geometries and winding arrangements, stator designs can minimize noise and vibration, enhancing the motor's usability in various applications.

In summary, the motor stator's performance is characterized by its efficiency, torque capability, effective thermal management, and low noise and vibration levels. These factors, combined with the stator's durability and customizability, contribute to the overall performance and reliability of the electric motor.