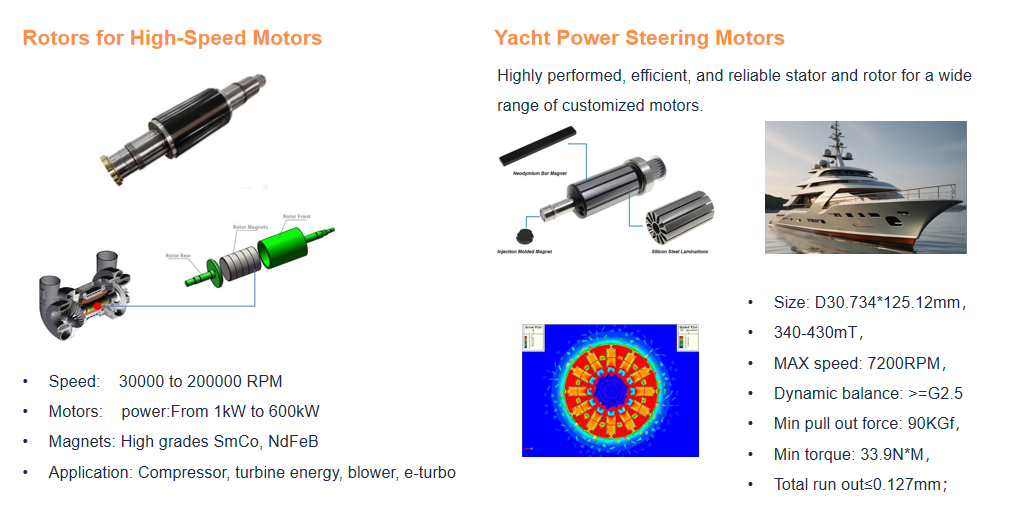

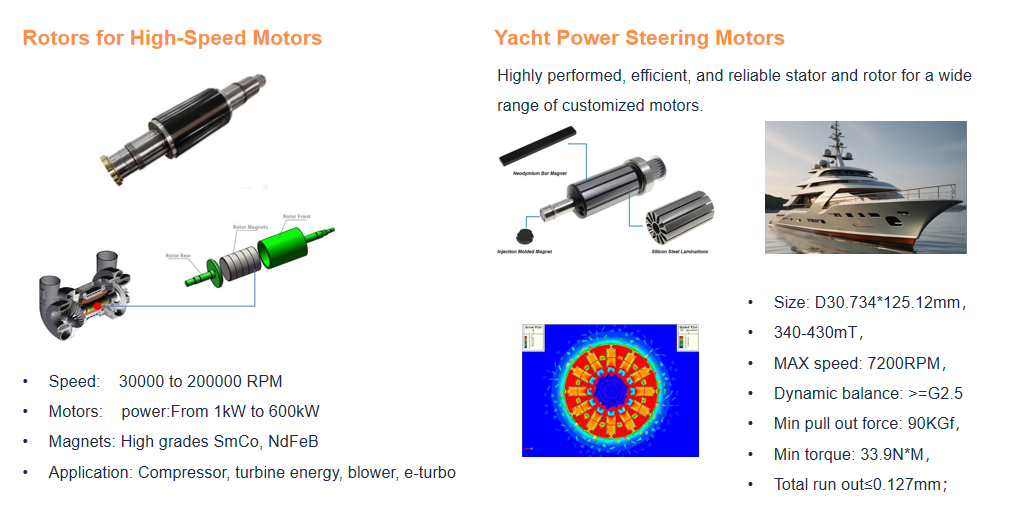

High-speed permanent magnetic motor rotors are a critical component in many modern applications, especially in the field of electrical engineering and motor design. They use permanent magnets, often made from materials such as neodymium (NdFeB), to create a consistent magnetic field. These rotors offer several distinct advantages and are used in various applications that benefit from their unique properties.

Advantages of High-Speed Permanent Magnetic Rotors:

Efficiency: High-speed permanent magnetic rotors are highly efficient. Unlike induction rotors, they do not require electrical energy to create a magnetic field, as this is provided by the permanent magnets. This reduces energy consumption and improves overall system efficiency.

Compact and Lightweight: The use of permanent magnets allows these rotors to be lighter and more compact compared to their electromagnetic counterparts. This makes them ideal for applications where space and weight are critical factors.

Low Heat Generation: Because there are no currents flowing through the magnets (as in the case of electromagnets), the heat generated in the rotor is significantly less. This minimizes the need for additional cooling systems and reduces thermal stress on the system.

High Power Density: Permanent magnetic rotors can achieve higher power densities. This means they can deliver more power relative to their size than many other types of motors, which is beneficial for high-performance applications.

Speed and Stability: These rotors can operate at very high speeds with good mechanical stability, thanks to the robustness of the magnetic field generated by the permanent magnets. This is particularly important in applications like turbines and high-speed compressors.

Low Maintenance: With fewer moving parts and no need for brushes (as used in some types of electric motors), permanent magnetic rotors generally require less maintenance. This reduces operational costs over the lifetime of the equipment.

Durability: The absence of electrical arcing and reduced heat generation contribute to the longer lifespan of these rotors under normal operating conditions.

Applications of High-Speed Permanent Magnetic Rotors:

Electric Vehicles (EVs): In the automotive sector, high-speed permanent magnetic rotors are used in the traction motors of electric vehicles. Their efficiency and power density are crucial for maximizing the range and performance of EVs.

Wind Turbines: They are used in wind turbine generators because they can efficiently convert wind energy into electrical energy at various wind speeds.

Industrial Machinery: High-speed motors with permanent magnetic rotors are used in industrial applications, including pumps, fans, and compressors where high efficiency and reliability are needed.

Aerospace: In aerospace, these rotors are used in applications ranging from main propulsion motors to auxiliary power units, where lightweight and high-efficiency solutions are critical.

Home Appliances: High-speed motors are found in home appliances like vacuum cleaners and blenders, where their efficiency and power contribute to better performance and energy savings.

High-Speed Trains: Used in the traction systems of high-speed rail, where efficient, high-power, and reliable motor systems are essential for safe and economical operation.

The introduction and development of high-speed permanent magnetic rotors have enabled significant advancements in motor technology, contributing to more sustainable and efficient energy use across multiple industries.