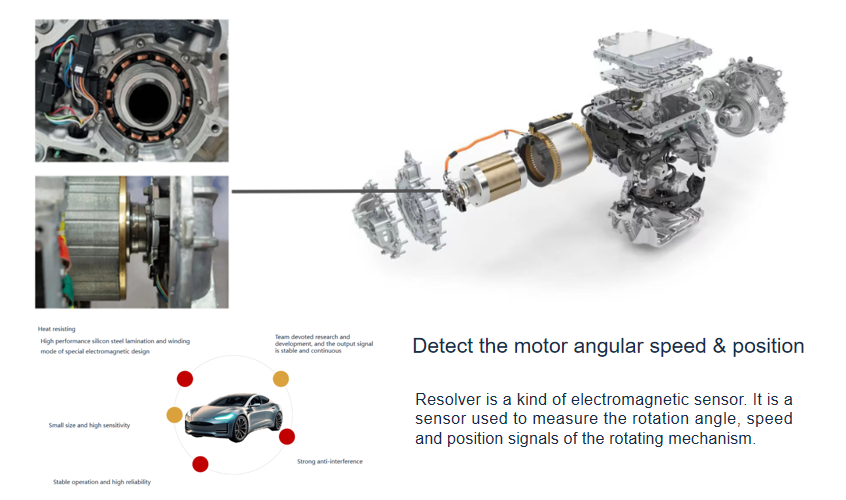

What is a resolver?

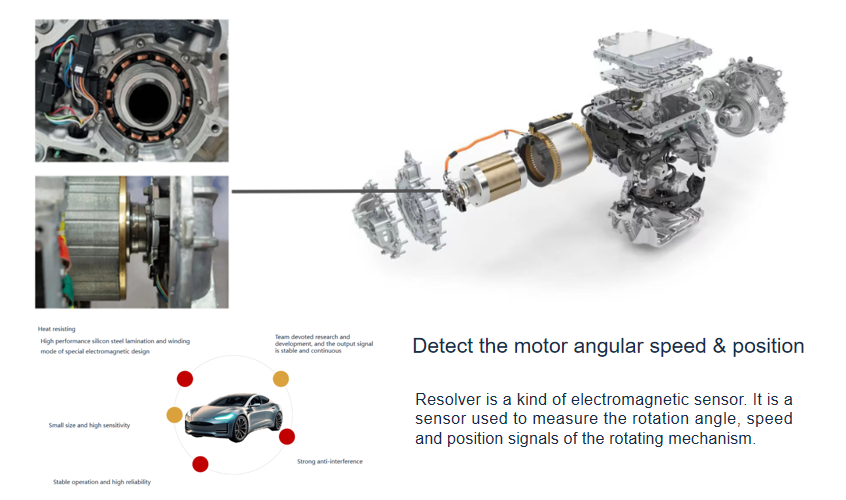

Resolver is the current domestic professional name, referred to as "rotating change". Because the basic principle of its work is the Transformer, the air gap of the "transformer" on the stator changes periodically during the work process by rotating the rotor, and then forms the function of monitoring the angular displacement (speed and position) of the motor rotor, so its full name is rotating transformer, which can also be translated into Rototary Transformer. However, this name is rarely used in English, and the general English name is Resolver.

The resolver, a precision electro-mechanical sensor, finds its place in a diverse array of applications across multiple industries, showcasing its versatility and reliability. Here's a concise exploration of its primary application domains within a 500-word limit:

In the realm of motor control and automation, resolvers are indispensable. They serve as vital position feedback devices in servo motors and permanent magnet synchronous motors (PMSMs), enabling precise control of angular position, velocity, and direction. This capability is crucial in industrial automation, where robots, conveyor systems, and other machinery rely on accurate positioning and synchronization for efficient operation.

Automotive applications also benefit significantly from resolvers. In electric vehicles (EVs) and hybrid electric vehicles (HEVs), resolvers play a critical role in the traction motor control system. By providing reliable position feedback, they contribute to the smooth and efficient operation of the electric drivetrain, enhancing the overall performance and range of EVs. Additionally, in advanced driver assistance systems (ADAS) and steering control, resolvers ensure precise angular measurement, aiding in the accurate and responsive operation of steering systems and lane-keeping assist features.

Aerospace and defense systems rely heavily on resolvers for their high accuracy and reliability. In flight control systems, resolvers measure the position of control surfaces, such as rudders and elevators, ensuring precise maneuvering and stability. They are also used in gyroscopes and gimbals, providing essential angular data for navigation and guidance systems.

Furthermore, resolvers find application in energy and power generation. In wind turbines and solar trackers, they enable precise positioning of rotor blades and solar panels, optimizing energy capture and conversion efficiency. In hydroelectric power plants, resolvers monitor the position of valves and turbines, ensuring safe and efficient operation.

Medical devices also leverage the precision of resolvers. In surgical robots, they provide accurate position feedback, enabling surgeons to perform complex procedures with high precision. Similarly, in diagnostic imaging equipment, resolvers ensure the precise positioning of imaging components, enhancing the quality and accuracy of medical images.

In summary, resolvers are pivotal in a wide range of applications, from motor control and automotive systems to aerospace, energy, and medical devices. Their ability to provide continuous, accurate position feedback in demanding environments makes them indispensable components in modern technology, driving efficiency, reliability, and precision across various industries.

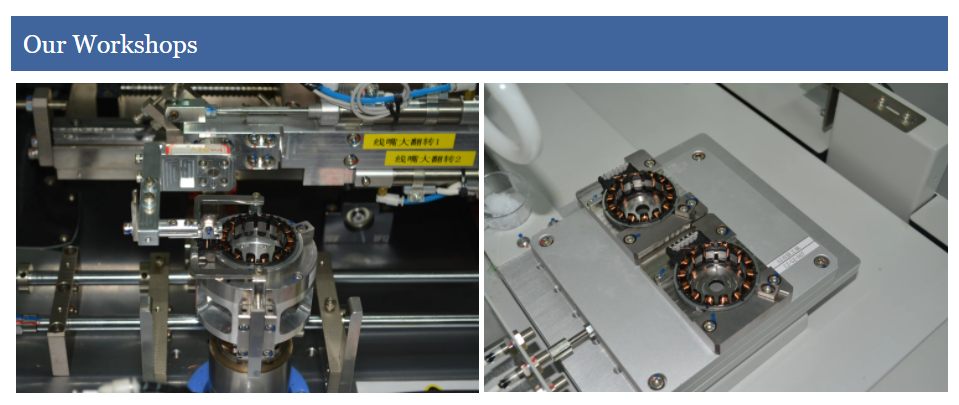

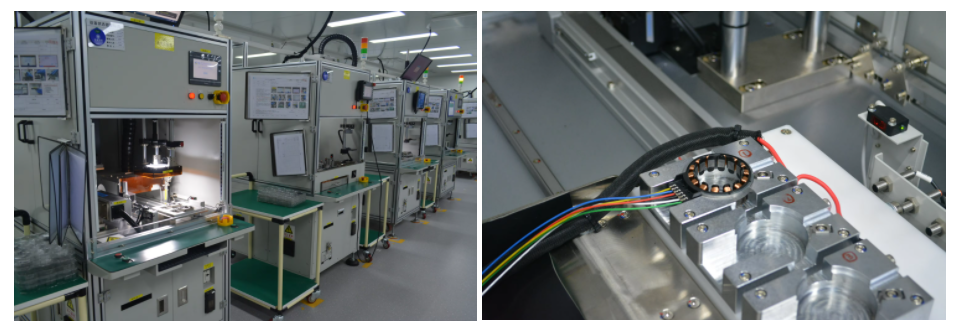

100% full inspection of production line

MES system each product of all raw materials + each process + factory 100% full inspection traceability.Providing high quality products through new technologies. We know that the trust of our customers is the cornerstone of our long-term cooperation.

Strong custom development ability

Support customized according to motor design, control and other special needs. Assist the client in the overall design, analysis and optimization of the drive unit and rotation cooperation, and analysis and solution of bench test problems; Rich experience in automotive project development, manufacturing and quality management.