Product Overview

The N52 Radially Magnetized NdFeB Magnet for Electronics is a high-performance magnetic component engineered for miniaturized electronic devices requiring precise magnetic field distribution. Unlike axially magnetized magnets, its radial magnetization pattern creates magnetic poles along the circumference, generating a uniform magnetic flux ideal for sensors, motors, and actuators . Crafted from premium N52 grade NdFeB alloy, this magnet delivers a BHmax of 49.5 - 52 MGOe—the highest in its class—while maintaining a compact form factor critical for modern electronics . Its sintered construction ensures exceptional coercivity (HCJ > 11.2 kOe) and thermal stability, making it a cornerstone of high-efficiency electronic systems.

Product Features

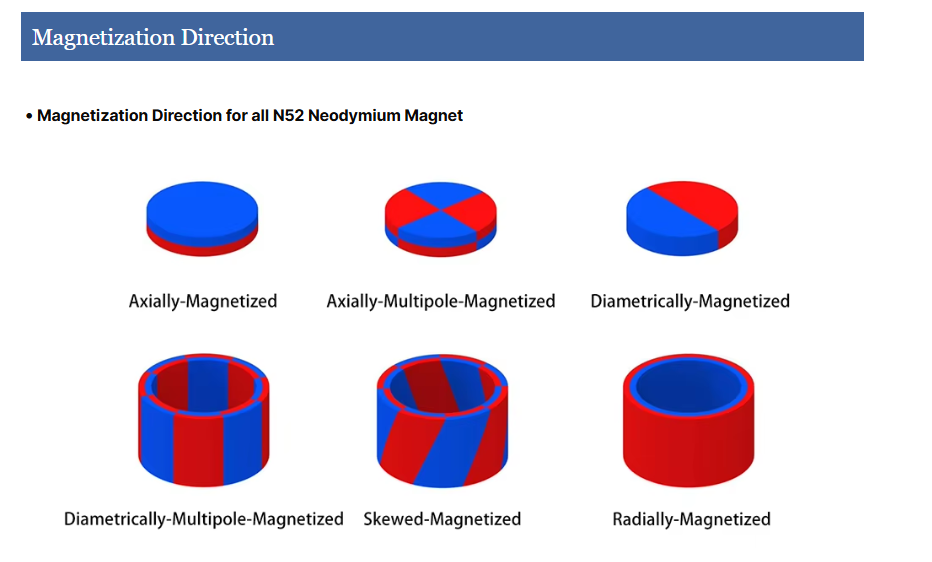

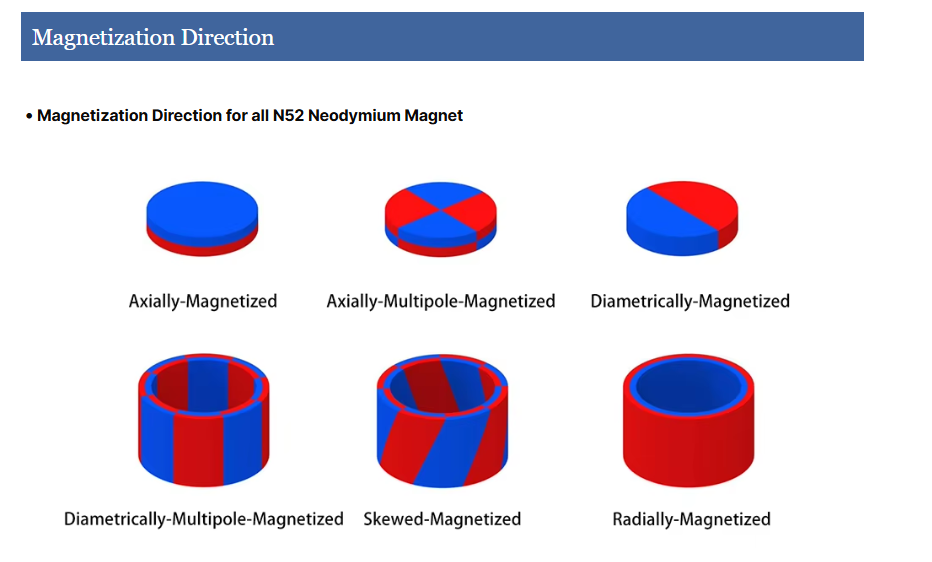

Radial Magnetization Advantage

The radial magnetization pattern aligns magnetic domains along the radius, producing a circumferential magnetic field that eliminates dead zones common in axially magnetized designs . This uniformity is essential for precision sensors and brushless motors, where consistent field strength ensures accurate operation.

Ultra-High Magnetic Energy

As an N52 grade magnet, it achieves a remanence (Br) of 14.5 - 14.8 kGs, delivering powerful magnetic force in tiny dimensions—critical for space-constrained electronics like smartphone cameras and medical micro-pumps .

Micro-Precision Manufacturing

Produced with tight dimensional tolerances (±0.02 mm), the magnet integrates seamlessly into miniature assemblies. Its smooth surface finish minimizes friction in rotating applications, such as spindle motors and linear actuators.

Corrosion-Resistant Coating

A Ni-Cu-Ni plating protects the magnet from oxidation and environmental contaminants, ensuring long-term reliability in humid or temperature-fluctuating environments like consumer electronics and medical devices .

Temperature Stability

With a maximum operating temperature of 80°C and reversible temperature coefficients of -0.12%/°C for Br, the magnet maintains stable performance in enclosed electronic systems where heat buildup is common .

Applications

Consumer Electronics

Used in smartphone camera autofocus motors, where radial magnetization enables precise lens movement; and in laptop cooling fans, enhancing airflow efficiency through uniform magnetic interaction with coils.

Medical Electronics

Integral to portable diagnostic devices, such as blood analyzers and insulin pumps, where compact size and reliable magnetic performance ensure accurate sensor readings and fluid control .

Industrial Sensors

Employed in position and speed sensors for robotics and automation, leveraging radial field uniformity to detect rotational motion with sub-millimeter precision.

Communication Devices

Used in microwave components and antenna systems, where stable magnetic fields enhance signal transmission and reduce interference in 5G and IoT devices.

FAQ

How does radial magnetization differ from axial magnetization?

Radial magnetization aligns poles along the magnet’s circumference, creating a tangential magnetic field ideal for rotational applications . Axial magnetization (poles on flat ends) is better suited for linear holding applications.

Can the magnet be customized for specific electronic devices?

Yes, manufacturers offer custom diameters (from 2mm to 50mm) and hole sizes to match unique device requirements, with radial magnetization patterns tailored to multi-pole designs (e.g., 4-pole for servo motors).

Is the magnet compatible with automated assembly processes?

Absolutely, its consistent dimensions and plating conductivity allow for robotic handling, soldering, and integration into PCB assemblies without performance degradation.

What precautions are needed when using the magnet in electronics?

Avoid exposure to temperatures exceeding 80°C to prevent demagnetization. Keep away from static discharge sources during installation, as NdFeB material is brittle and may chip under impact.