The resolver and artificial intelligence (AI) represent two distinct yet interconnected technologies that drive innovation and efficiency across various industries. Here's a concise exploration of both within a 500-word limit:

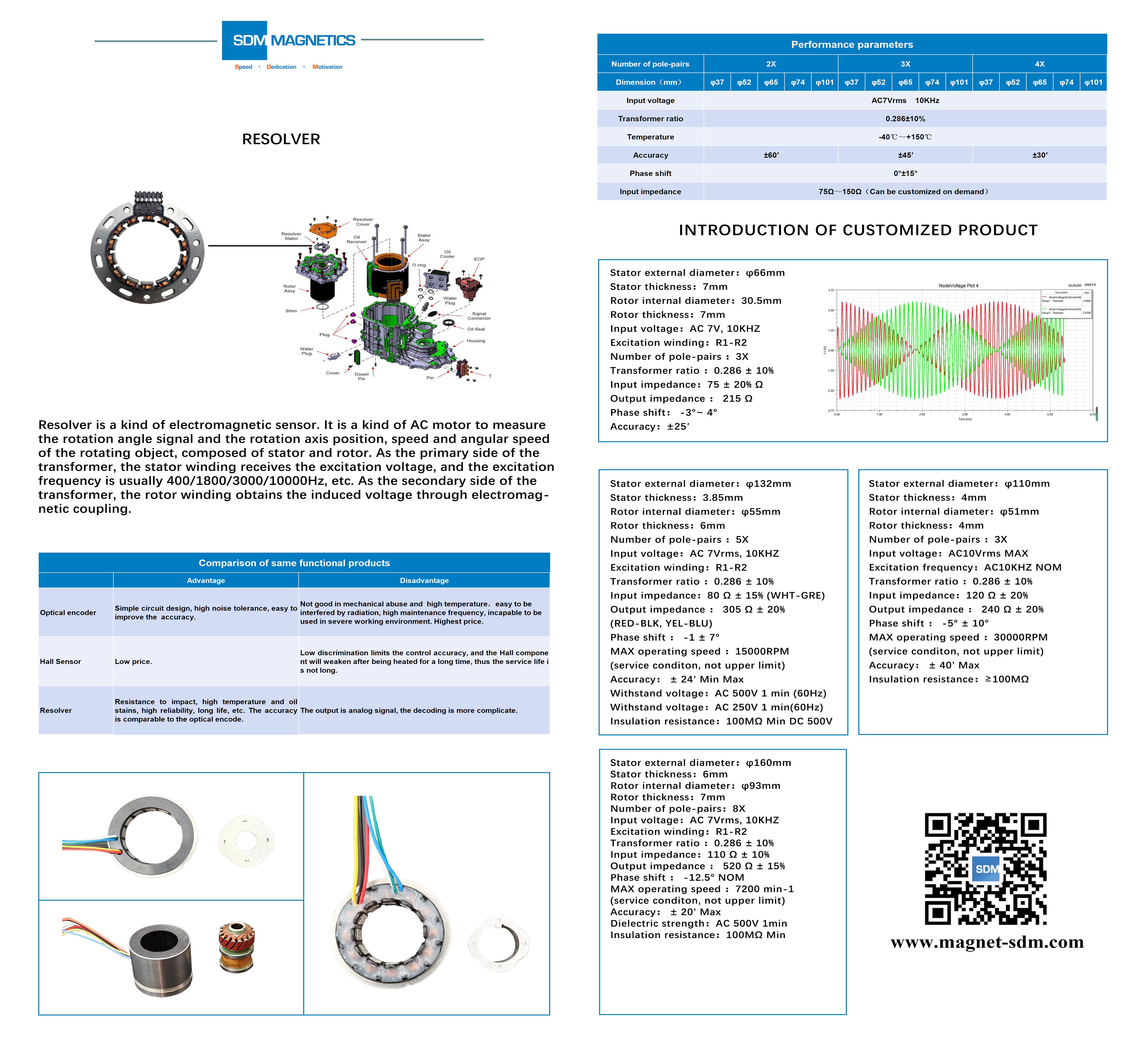

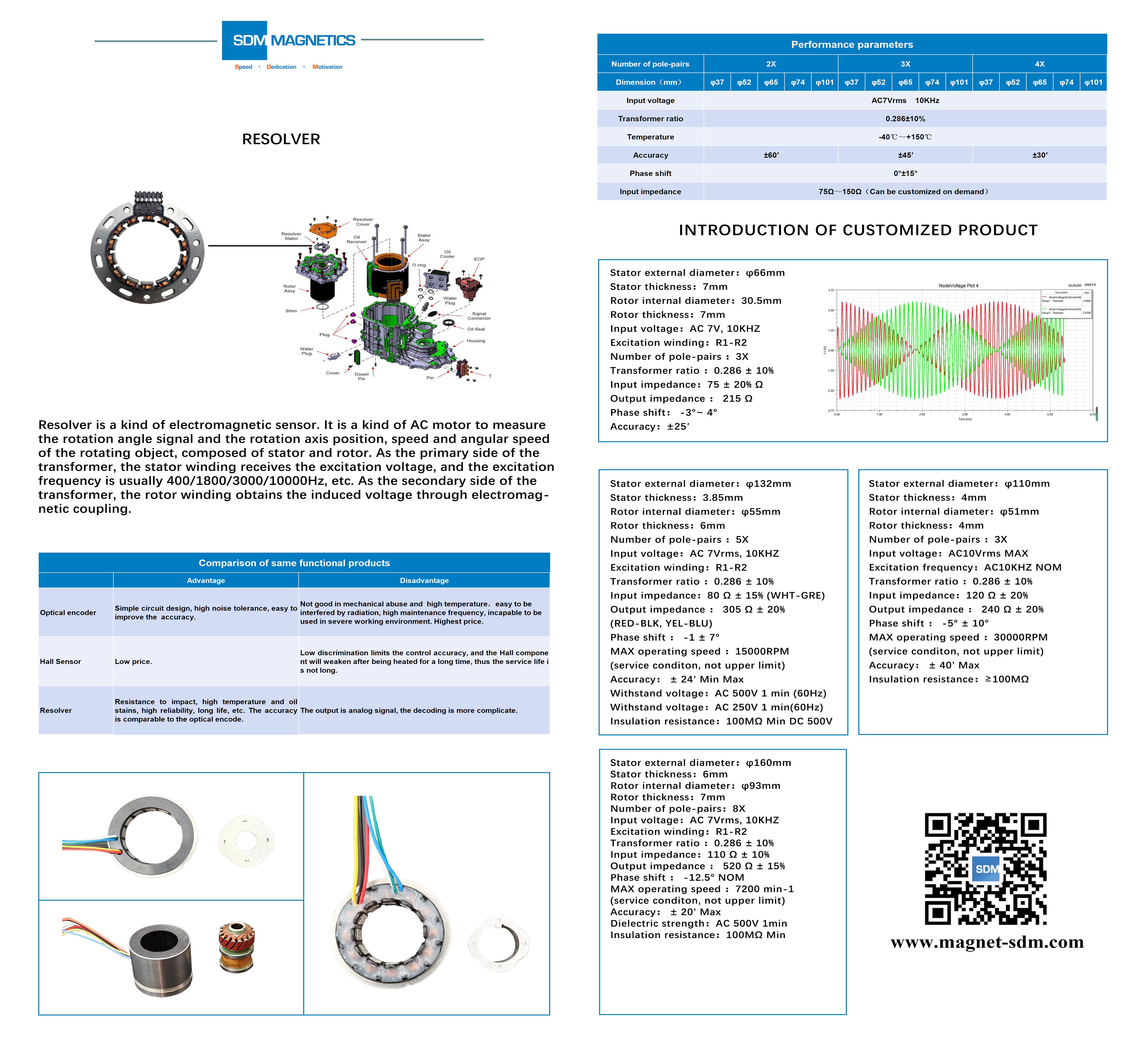

The resolver is an electro-mechanical sensor that excels in precision measurement of angular position. It operates on the principle of electromagnetic induction, utilizing a rotating rotor and stator to produce an analog signal that can be interpreted to determine the exact angle of rotation. Resolvers are renowned for their high accuracy, reliability, and robustness, making them ideal for applications requiring precise positioning and control. In industrial automation, for instance, resolvers enable the precise control of servo motors and other machinery, ensuring smooth and efficient operations.

On the other hand, artificial intelligence (AI) represents a broader field of computer science focused on creating systems capable of performing tasks that typically require human intelligence. AI leverages algorithms, data, and computational power to learn, reason, and make decisions. Machine learning, a subset of AI, involves training algorithms on large datasets to identify patterns and make predictions. AI has revolutionized numerous industries, from healthcare and finance to transportation and entertainment, by providing solutions that are more efficient, accurate, and personalized than traditional methods.

The intersection of resolvers and AI lies in their combined ability to enhance precision and efficiency in complex systems. For example, in autonomous vehicles, resolvers provide crucial position feedback to the AI-driven control systems, enabling precise navigation and obstacle avoidance. Similarly, in robotics, resolvers ensure the accurate positioning of robotic arms and other components, while AI algorithms optimize task execution and adapt to changing environments.

Moreover, AI can be used to enhance the performance of resolvers. By analyzing data from resolvers and other sensors, AI algorithms can identify patterns and anomalies, leading to improved maintenance and fault detection. This predictive maintenance approach can significantly reduce downtime and operational costs, enhancing the overall reliability and efficiency of systems incorporating resolvers.

In conclusion, resolvers and AI are two powerful technologies that, when combined, can drive significant advancements in precision and efficiency. Resolvers provide the foundational precision required for accurate positioning and control, while AI leverages data and algorithms to optimize system performance and adapt to changing conditions. Together, they represent a powerful duo that is shaping the future of technology and innovation.

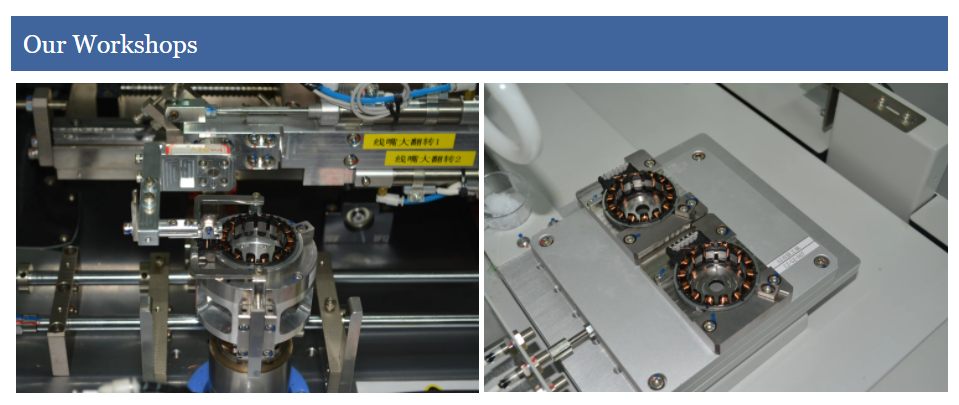

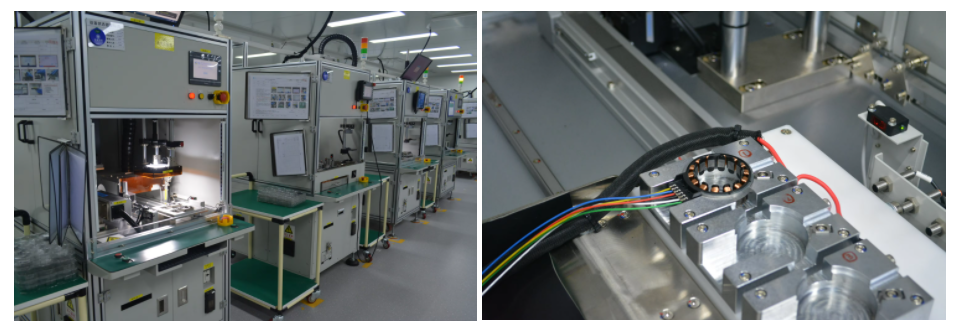

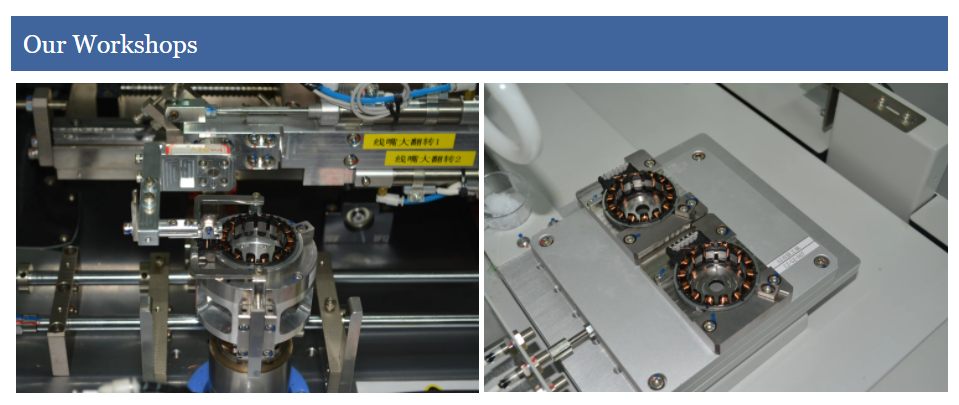

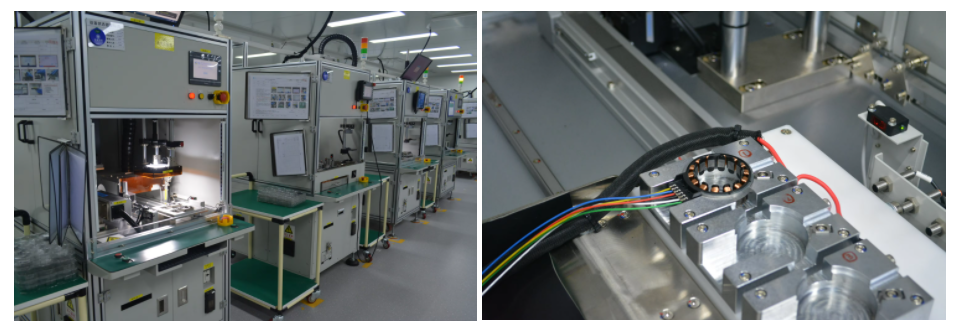

100% full inspection of production line

MES system each product of all raw materials + each process + factory 100% full inspection traceability.Providing high quality products through new technologies. We know that the trust of our customers is the cornerstone of our long-term cooperation.

Strong custom development ability

Support customized according to motor design, control and other special needs. Assist the client in the overall design, analysis and optimization of the drive unit and rotation cooperation, and analysis and solution of bench test problems; Rich experience in automotive project development, manufacturing and quality management.