Product Overview

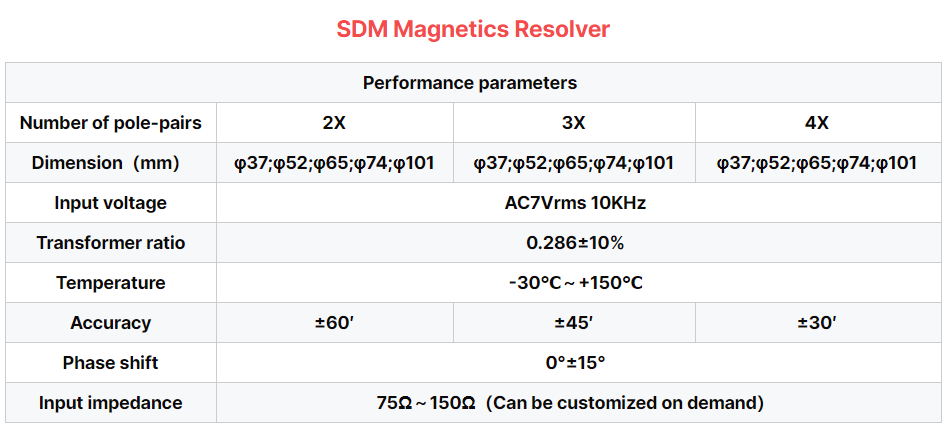

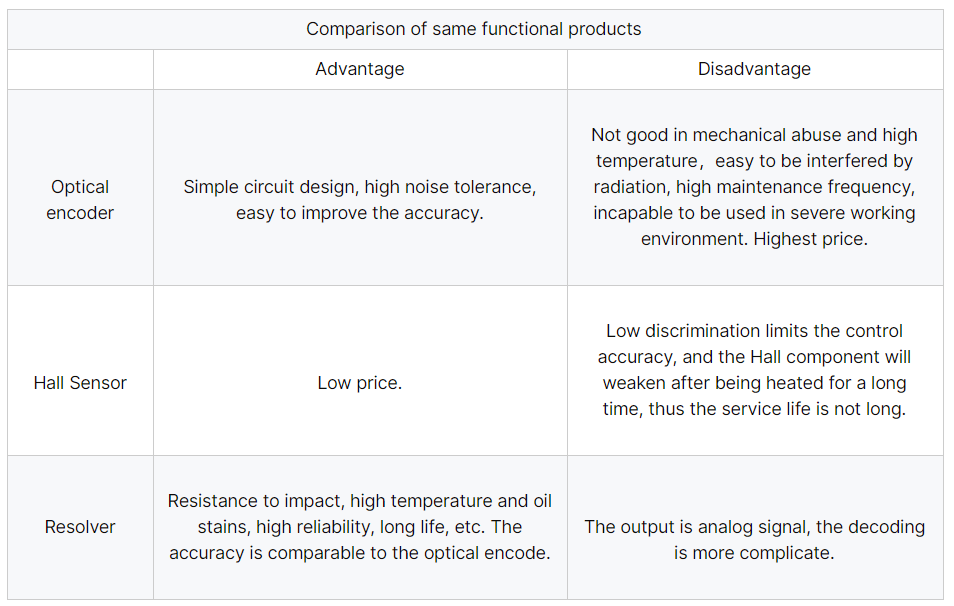

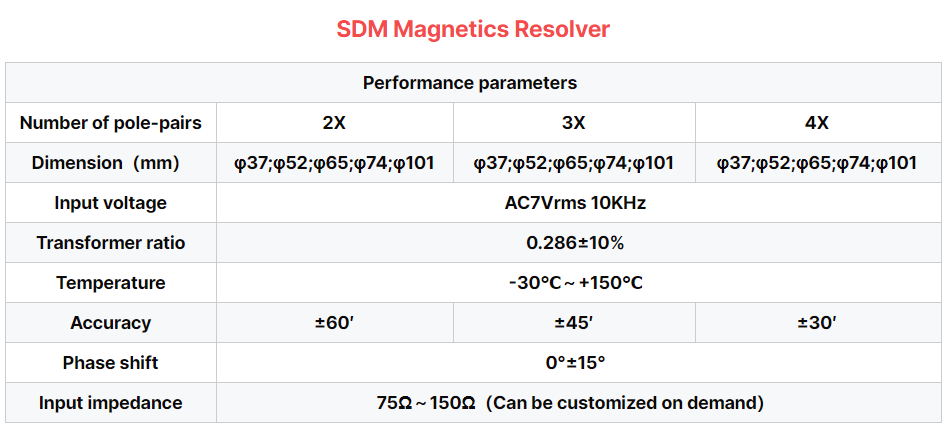

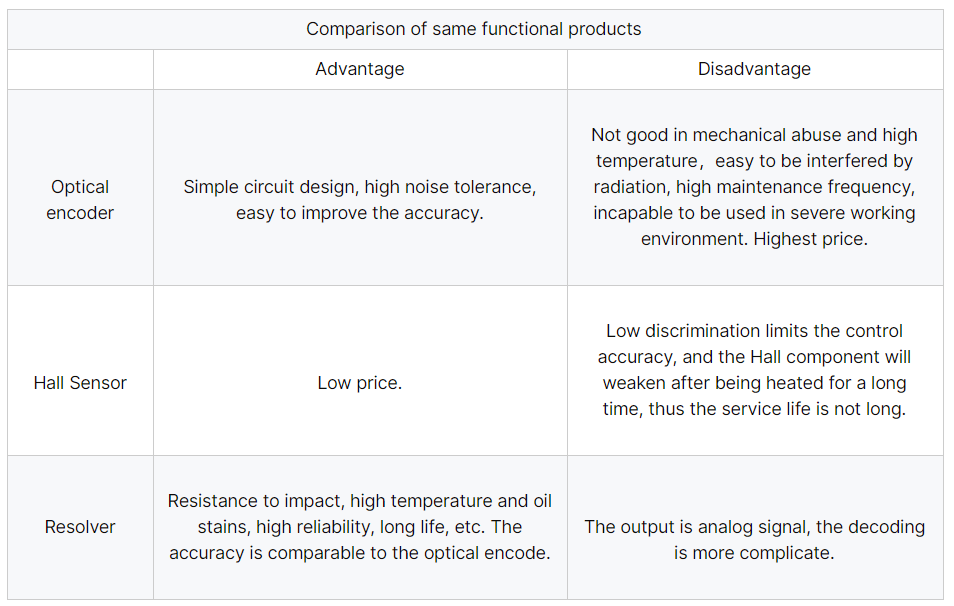

Precision Rotary Resolvers for EV Motors are advanced position-sensing transducers designed to deliver accurate rotational feedback in electric vehicle (EV) drivetrains. Unlike incremental encoders, resolvers operate as brushless rotary transformers, using inductive coupling between rotor and stator windings to generate analog position signals—ensuring reliability in the harsh environments of automotive applications . Engineered to withstand extreme vibrations, temperature fluctuations, and electromagnetic interference (EMI), these resolvers provide absolute position data critical for optimizing motor efficiency, torque control, and regenerative braking in EVs. With an operating temperature range of -30°C to 125°C and robust construction, they outperform traditional sensors in durability and longevity .

Product Features

High-Accuracy Position Feedback

Featuring sub-degree resolution and linearity errors below ±0.1%, these resolvers deliver precise real-time data to EV motor controllers, enabling smooth acceleration, precise speed regulation, and efficient power management. Their analog output eliminates digital signal dropout risks in noisy electrical environments.

Rugged Environmental Resistance

Constructed with aluminum or stainless steel housings, the resolvers achieve an IP67 ingress protection rating, making them resistant to water, dust, oil mist, and coolants commonly found in automotive engine bays . This sealing ensures reliable operation even in wet or dirty conditions.

Vibration and Shock Tolerance

Designed to withstand continuous mechanical shock (up to 50G) and vibration (up to 20G), these resolvers maintain performance in rough driving conditions, extending service life in EV applications where durability is paramount .

EMI Immunity

Unlike optical encoders, resolvers are inherently immune to electromagnetic interference from EV powertrains, inverters, and high-voltage systems. This immunity ensures stable signal transmission without data corruption or latency.

Compact Integration

With options for solid shaft or hub shaft designs, and oversized double-row bearings supporting up to 100 lbs radial load and 50 lbs axial load, these resolvers fit seamlessly into EV motor end bells or transmission housings without compromising performance .

Applications

EV Traction Motors

The primary application is in electric vehicle traction motors, where precise rotor position feedback enables vector control algorithms to optimize torque output and energy efficiency, directly impacting driving range and acceleration.

Hybrid Vehicle Powertrains

Used in plug-in hybrid (PHEV) systems to synchronize internal combustion engine (ICE) and electric motor operation, ensuring smooth transitions between power sources.

Electric Power Steering (EPS)

Integrated into EPS systems to provide real-time steering angle data, enhancing vehicle stability and driver safety through responsive handling.

Battery Management Systems (BMS)

Auxiliary use in BMS cooling fan motors, where resolver feedback regulates fan speed based on battery temperature, preventing overheating.

FAQ

How do resolvers differ from encoders in EV applications?

Resolvers use inductive coupling and analog signals, offering superior resistance to vibration, moisture, and EMI compared to optical encoders . They have no moving parts except the rotor, reducing wear and extending service life in high-cycle EV operations.

What maintenance is required for the resolver?

Resolvers are maintenance-free due to their brushless design and sealed construction. Unlike encoders with fragile optics, there are no components to clean or replace under normal operating conditions.

Can the resolver operate in sub-zero temperatures?

Yes, the resolver functions reliably from -30°C to 125°C, making it suitable for EVs in cold climates without performance degradation .

How is the resolver calibrated?

Factory calibration ensures accuracy out of the box, with most EV manufacturers integrating auto-calibration routines in motor controllers to compensate for installation tolerances. No manual adjustment is required during vehicle assembly.