You use resolvers to check rotation, position, and speed in machines. These devices work well when you need strong and steady feedback. You can find them in servo motor feedback, steel mills, paper mills, oil and gas production, jet engine fuel systems, aircraft actuators, communication systems, and military vehicles. This article talks about electromechanical resolvers. They help you control equipment even in hard places.

Key Takeaways

Resolvers give exact position and speed information. This helps machines like robots and aircraft work well.

These devices work great in tough places. They can handle heat, dust, and shaking. This makes them work reliably.

Resolvers change movement into strong analog signals. These signals do not get messed up by electrical noise. This makes feedback better.

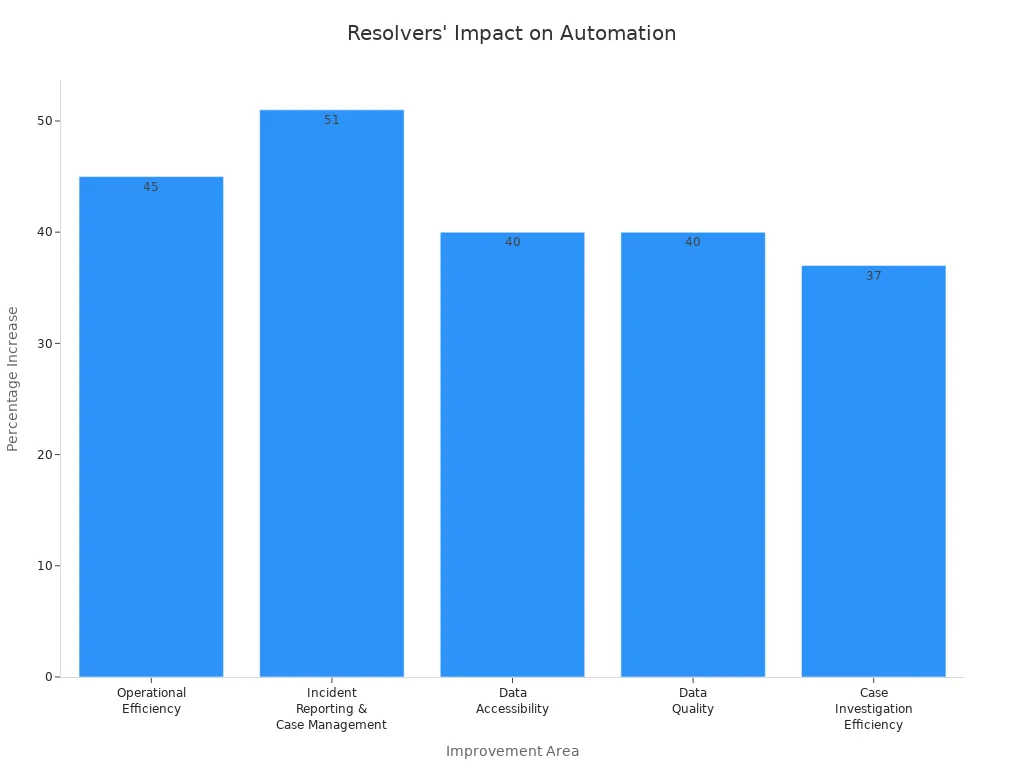

Using resolvers can make automation systems work 45% better. They can also lower problems by 51%.

Picking resolvers for your projects makes them safer and last longer. Machines work better in hard conditions with resolvers.

Main Applications of Resolvers

Position Sensing

Resolvers help you know where a spinning part is. They give clear position data, even in places like steel mills and oil sites. You find resolvers in servo motors and jet engine fuel systems. Aircraft actuators also use them. These devices help machines work safely and without problems.

Give clear position sensing

Work well in tough places

Are trusted feedback devices for servo motors

Resolvers are very reliable. They work well and have a strong reputation for sensing rotary position.

Resolvers keep working when dust or heat stops other sensors. The table below shows how resolvers and encoders are different:

Feature | Resolvers | Encoders |

Accuracy | ±30 arc-seconds | Can have higher resolution |

Reliability | Very tough, works in hard places | Can be affected by the environment |

Position Data | Gives absolute position | Gives relative position |

Durability | Handles dust, dirt, and moisture | Can break in tough places |

Temperature Tolerance | Works above 200°C | Can be hurt by heat |

Response Time | Fast, under 10 ms | Depends on the type |

Speed Feedback

Resolvers measure how fast things spin. This is important in robots, CNC machines, radar antennas, and ship navigation tools. Resolvers send strong signals that are not easily messed up by electrical noise. These signals help you check both speed and position.

Resolvers give speed feedback with strong signals. These signals are not easily affected by noise.

They make wave-like signals that can change to digital signals for clear position and speed feedback.

Resolvers are built to last in tough places. They work well even with heat, shock, and vibration.

Control Systems

Resolvers are used in control systems that need exact feedback. In closed-loop systems, they tell you the position and speed of moving parts. This helps machines work the way you want. You see resolvers in factories. They help robots and machines move with care and repeat the same actions.

Resolvers give exact feedback on position and speed. This is important for control systems.

They help keep things accurate and repeatable in factories. This is needed for automation.

AI uses resolver data to make machines work better and faster.

Resolvers in Automation

Resolvers are found in many automated systems in different industries. They help control robots, AC drives, and metal-making machines. These places need sensors that keep working when things get hot or dirty.

Application Type | Description |

Safety-related applications | Resolvers are trusted for their accuracy and reliability. They are good for safety jobs. |

Servo Drives for Industrial Robotics | Resolvers are often used in servo drives for robots. |

Robotic Arms | Resolvers help robotic arms know their position. |

Integrated Actuators | Resolvers are used in servo drives for actuators. |

Resolvers are also used in systems that do jobs like booking orders, making invoices, and doing maintenance. These devices help everything run well, even when the place is not perfect.

Note: This part talks about electromechanical and industrial resolvers. It does not talk about DNS or software resolvers.

How Resolvers Work

Signal Conversion

Resolvers are sensors that change movement into electrical signals. They have a simple design with a rotor and a stator. The rotor spins and changes the voltage in the stator. The stator has two windings set apart at 90 degrees. This helps you find the rotor’s angle.

Resolvers turn rotation into analog electrical signals.

The main winding gets a wave-like signal. This makes two signals on the other windings.

These signals match the sine and cosine of the shaft’s angle. This helps you measure the angle very well.

A resolver-to-digital converter reads these signals. It shows the position and speed of the spinning part.

Tip: The sine and cosine signals from a resolver are strong. They do not get mixed up by electrical noise. You get good feedback even in tough places.

Analog Operation

Resolvers use smooth signals, not digital pulses. This makes them different from digital sensors like encoders. You need a special converter to use resolver signals in digital systems. The table below shows how analog resolvers and digital encoders are different:

Feature | Resolvers (Analog) | Encoders (Digital) |

Input Signal | Needs AC sine wave for power | Uses simple DC voltage |

Output Signal | Gives SINE/COSINE analog signals for position | Makes digital pulses for motion changes |

Accuracy | Usually less accurate (3 arcminutes) | Often more accurate (20 arcseconds) |

Reliability | Works better in tough places | Can be hurt by heat and shaking |

Integration | Needs A/D converters for digital systems | Can connect right to digital controllers |

You can trust analog resolvers in places with heat, dust, or shaking. They keep working when digital sensors might stop. If you want to use them with a computer, you just add a converter.

Resolver Advantages

Reliability

Resolvers work well in tough places. They keep working when other sensors stop. You can check how reliable they are with some numbers:

Mean Time Between Failures (MTBF)

Mean Time to Repair (MTTR)

Customer-Reported Defects

These numbers show how often resolvers break. They also show how fast you can fix them. You can see how many problems people report. These things help you know if your machines will keep working.

Brushless resolvers have a simple build. They use wire, bearings, lubricant, and a strong case. Good materials let them work in hot, dusty, or shaky places. If the bearings last, the resolver keeps working. You can move the electronics away from the sensor. This keeps heat, water, and shaking from hurting the electronics. Resolvers are used where it is very hot or there is a lot of shaking.

Accuracy

Control systems need accurate feedback. Resolvers help you measure position and speed well. You can check accuracy in different ways:

Interaxis error shows how much the angle can drift.

Linearity error tells if voltage changes smoothly.

Velocity error matters when things move fast.

Good accuracy helps your control system work better. If the resolver gives wrong data, machines may not move right. Many things can change accuracy, like reference frequency and bandwidth. You need to watch these details for the best results.

High accuracy helps control systems work well.

Errors can cause problems in motion control.

You can make accuracy better by changing settings.

Durability

Resolvers are known for being tough. You can use them in factories, planes, and military vehicles. They resist heat, shaking, and dirt. Here are some things that make them strong:

Strong design lets them work in hot and shaky places.

They keep giving good feedback even with dust or noise.

You can use them in planes and military jobs without worry.

They resist shock, shaking, and temperature changes.

The table below shows how resolvers and encoders do in tough places:

Feature | Resolvers | Encoders |

Onboard Electronics | None | Present |

Temperature Resistance | Very high temperatures | Sensitive above 248°F (120 °C) |

Vibration Resistance | High | Sensitive to mechanical vibrations |

Contaminant Resistance | High (dust, pollutants) | Low |

Ionizing Radiation Resistance | High | Low |

Resolvers are good when you need sensors that last and keep working in hard places.

Industries Using Resolvers

Aerospace

Resolvers are used in many aerospace systems. They help control flap positions. They measure jet engine fuel flow. They guide flight surface actuators. These devices work well in tough places. They handle high heat and strong shaking. You can trust them for accurate feedback. They still work when there is electrical noise.

Application Area | Specific Use Case |

Aeronautics | Position of flaps |

Military | Transportation systems |

Resolvers in jet engines and flight controls have many benefits:

Benefit | Description |

Robustness | Very tough, works in heat and vibration. |

Accuracy | Gives exact position feedback with analog signals. |

Noise immunity | Blocks electrical noise for steady performance. |

Temperature stability | Stays reliable in hot and cold places. |

Tip: Resolvers in planes keep working when other sensors stop.

Manufacturing

Resolvers are found in many factory machines. They help control robots, presses, and metal systems. These devices give real-time feedback. This helps you run machines safely and well. In steel mills, robots use resolvers to check molten steel temperature. They add casting powder and mark steel coils.

Temperature robots use resolvers to check hot steel.

Casting robots use them to add powder during pouring.

Marking robots use them to spray info on steel.

Resolvers help make factories safer and more productive. The table below shows important benefits:

Benefit | Description |

Enhanced Positional Feedback | Lets you watch press cycles and lower accident risks. |

Integration with Safety Systems | Works with safety controls to protect workers. |

Improved Cycle Times | Helps presses run faster and keep quality. |

Real-time Diagnostics | Lets you find and fix problems quickly. |

Durability | Handles tough and hot jobs. |

Automotive

Resolvers are used in cars and electric vehicles. They measure motor position and speed. These devices connect to the motor’s shaft. They send signals to the controller. This helps control the motor very well. They work even in noisy or rough places. In electric vehicles, resolvers help motors run better and smoother.

Advantage | Description |

High Efficiency | Makes electric motors work better and go farther. |

Precision Control | Allows quick control of motor power. |

Robustness | Works well in heat and shaking. |

Position Retention | Keeps position data even when power is off. |

Resolvers help car motors run safely and smoothly. They make sure feedback is always right. This is important for safety and performance.

You use resolvers to get correct position and speed data. They work well in places that are hot or rough. Resolvers give you live data and do not need much fixing.

Picking the best sensor helps your project stay safe. It also makes things work better and last longer.

FAQ

What makes a resolver different from an encoder?

You use a resolver when you need a sensor that works in tough places. Resolvers use analog signals and handle heat, dust, and vibration. Encoders use digital signals and may stop working in harsh conditions.

Can you use a resolver in a digital control system?

Yes, you can. You need a resolver-to-digital converter. This device changes the resolver’s analog signals into digital data. Your control system can then read the position and speed.

How long does a resolver last?

Resolvers last a long time. You often see them work for years without problems. Their simple design and strong build help them resist damage from heat, dust, or shaking.

Where do you find resolvers in everyday machines?

You find resolvers in robots, electric cars, airplanes, and factory machines. They help these machines know their position and speed. This keeps everything running safely and smoothly.

Do resolvers need a lot of maintenance?

You do not need to do much maintenance for resolvers. Their simple parts and strong cases help them keep working. You only need to check them sometimes for wear or dirt.