Ingenious magnet arrangement creates the magic of a unilateral strong magnetic field.

In modern technology, a special magnet structure—the Halbach array—can create an extremely strong unilateral magnetic field, playing a significant role in various fields such as maglev trains, MRI, and high-efficiency motors.

The bonding method is one of the most classic and widely used processes for manufacturing this remarkable magnet structure. This article will guide you through the intricacies of the Halbach array bonding fabrication process.

A Halbach array consists of rare-earth permanent magnet materials, arranged by orienting the magnetization direction of individual permanent magnets in a specific pattern. This concentrates the magnetic field lines on one side of the array while weakening them on the opposite side, achieving the ideal unilateral magnetic field.

This design is crucial in engineering. Due to its ideal magnetic field distribution characteristics, it is widely applied in industrial fields such as NMR (Nuclear Magnetic Resonance), magnetic levitation, and special permanent magnet motors.

Bonding Method: A Classic Halbach Array Fabrication Process

The bonding method is one of the most direct ways to fabricate a Halbach array. Its basic principle is: According to the array's topology, pre-magnetized magnet segments are bonded together using magnet adhesive.

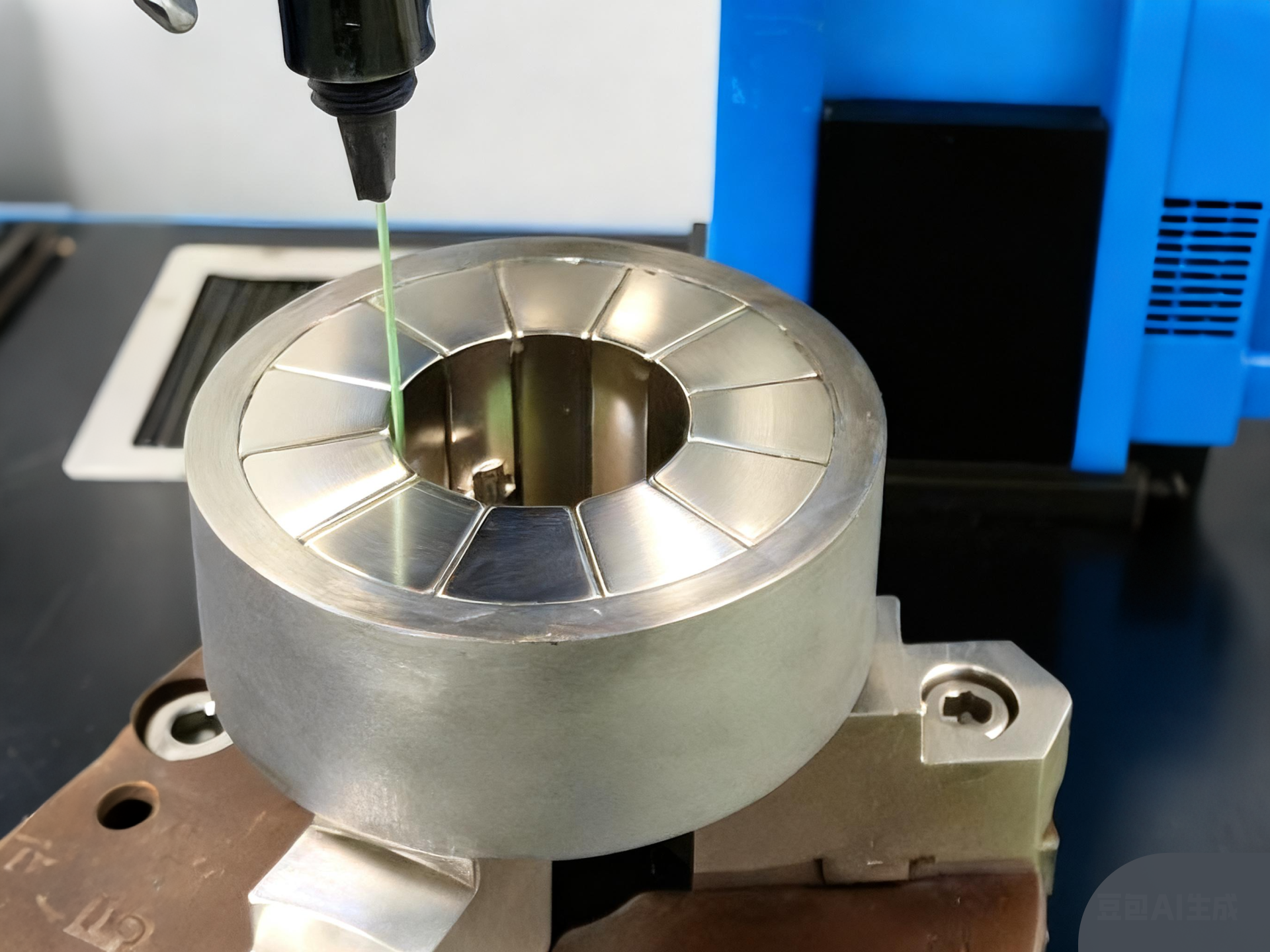

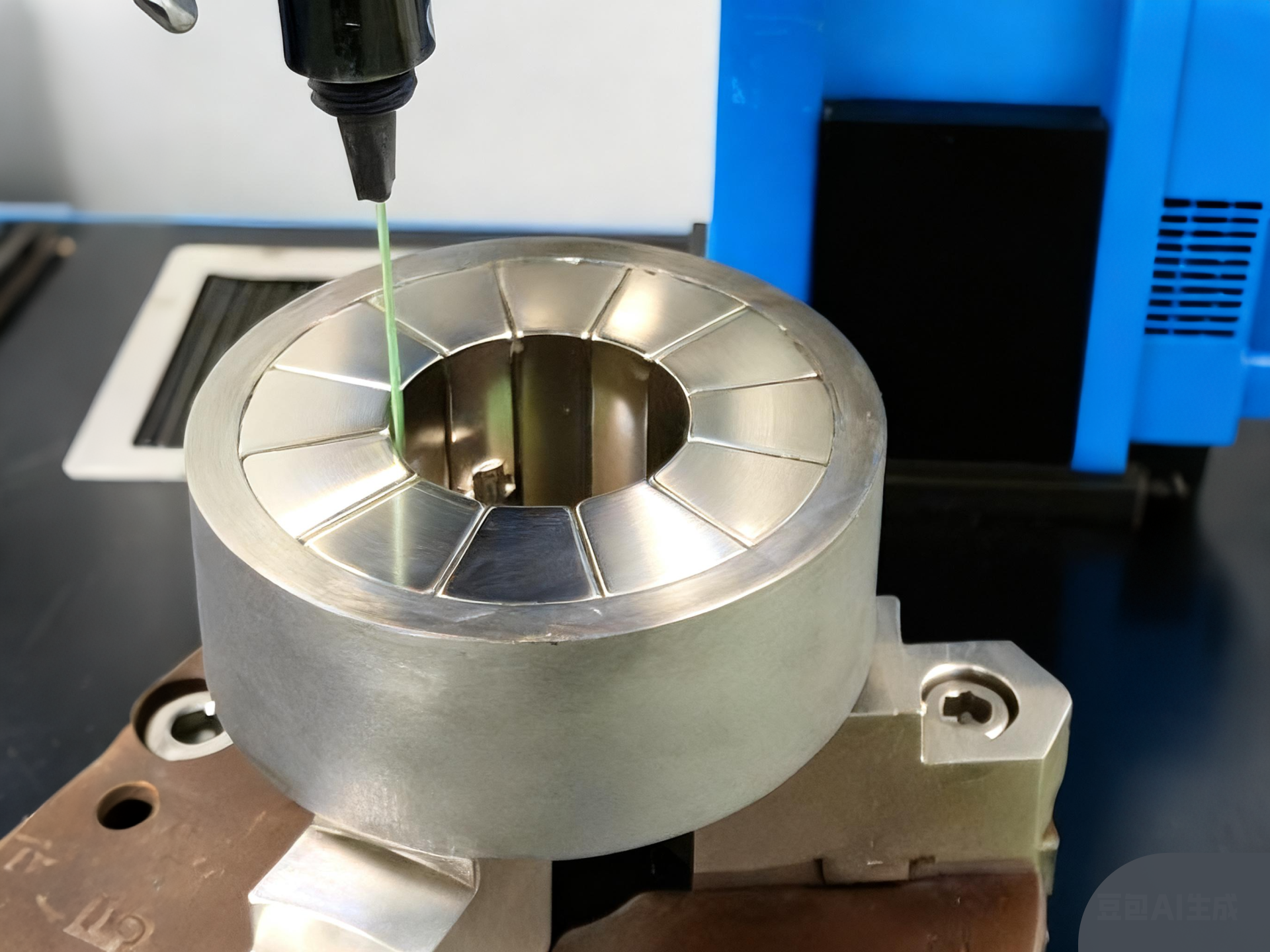

Because the magnet segments exert strong repulsive or attractive forces on each other after magnetization, specialized jigs and fixtures are required to clamp and hold them in place during the bonding process.

This method has relatively low production efficiency but is easier to implement, making it more suitable for the laboratory research and development stage or small-scale production.

Detailed Bonding Process Flow

Magnet Segment Preparation and Magnetization

First, multiple small magnet blocks need to be prepared. These blocks are cut and initially processed according to the design requirements.

The traditional bonding method involves pre-magnetizing these magnet blocks before assembly.

Array Assembly and Fixation

Due to the strong repulsive forces between magnetized segments, the assembly process relies on specialized molds and fixtures to secure their positions.

For instance, an innovative assembly technique uses non-magnetized assembly, significantly reducing assembly difficulty and increasing operator safety.

Bonding and Curing

A special magnet adhesive is used to bond the magnet segments together.

During bonding, the precise alignment of the magnet segments must be maintained until the adhesive is fully cured. Some processes place the assembled product into an oven for baking to accelerate the curing process and enhance bond strength.

Post-Processing and Finishing

After the adhesive cures, the molds and fixtures can be carefully removed.

In some processes, the assembled magnet component may require further surface treatment and precision machining to achieve the final dimensional and shape specifications.

Technical Challenges and Solutions in Bonding

Strong Repulsive Forces Between Magnets

Challenge: The powerful repulsive forces between magnetized segments make assembly difficult and pose operational safety risks.

Solution: Use specially designed molds and fixtures to counteract the repulsive forces. Another effective method is to assemble the magnets before magnetization and then magnetize the complete assembly, thus entirely avoiding the repulsion issue during assembly.

High Assembly Precision Requirements

Challenge: The magnetic field distribution of the Halbach array is highly sensitive to the alignment precision of the magnet blocks; even minor misalignments can affect overall performance.

Solution: Adopt segmented fixtures for assembly. For example, the "segmented inner rotor ring Halbach array magnet assembly fixture" developed by Instec Company allows for controllable gaps, ensuring the finished product has minimal deviation from the ideal state.

Difficulty Assembling Small-Size Arrays

Challenge: Smaller sizes increase assembly difficulty and demand higher operational precision.

Solution: For small-size Halbach arrays, specially designed magnet structures (like a "口"-shaped structure) can be employed, along with introducing new magnetization methods to optimize the assembly process.

Advantages and Limitations of the Bonding Method

Advantages

· Ease of Implementation: Relatively simple in principle and easier to implement compared to other methods.

· Suitability for R&D: Highly suitable for the laboratory R&D stage and small-batch production.

· High Flexibility: Capable of fabricating Halbach arrays in various shapes and sizes, including linear and circular arrays.

Limitations

· Low Efficiency: Manufacturing efficiency is relatively low, making it unsuitable for large-scale production.

· High Cost: Production costs are relatively high due to the predominance of manual or semi-automated operations.

· Strength Depends on Adhesive: The mechanical strength of the magnet structure heavily relies on the quality and bonding effectiveness of the adhesive.

Application Scenarios for the Bonding Method

Halbach arrays manufactured by the bonding method have demonstrated value in numerous fields:

· Magnetic Levitation Technology: Maglev trains utilize Halbach arrays to achieve powerful directional magnetic fields.

· Medical Equipment: Medical devices like MRI rely on Halbach arrays to provide stable and uniform magnetic fields.

· High-Efficiency Motors: Special permanent magnet motors use Halbach arrays to improve efficiency and power density.

· Industrial Equipment: Various industrial applications requiring strong unilateral magnetic fields.

Future Outlook

With technological advancements, the bonding process for Halbach arrays is also continuously improving.

New fixture designs, assembly techniques, and developments in materials science are constantly enhancing the efficiency and quality of the bonding method, enabling this classic approach to meet broader application needs.

As a fundamental manufacturing method for Halbach arrays, the bonding method, despite its limitations, continues to play an irreplaceable role in R&D and small-batch production due to its simplicity and ease of implementation.

With the emergence of new materials and processes, the bonding method may also encounter new development opportunities, providing support for manufacturing even more powerful and precise Halbach arrays.

The Halbach array bonding fabrication process is an exquisite art that commands the magnetic field. It will continue to play a significant role in technological development, propelling magnetic technology to higher levels.