The Power in the Coils: Unveiling the Carbon Fiber Wrapping Process That Increases Motor Speed by 10x

How can a carbon fiber, thinner than a human hair, build a Great Wall on a high-speed motor rotor to withstand immense centrifugal forces?

Dongfeng Motor's released "MACH E" 800V ultra-high-speed electric drive system boasts a motor with a maximum operating speed of 25,000 rpm and a limit speed exceeding 34,447 rpm.

Behind this astonishing speed lies a precision process – carbon fiber wrapping technology.

01 The Strength Bottleneck of High-Speed Motors

High-speed motors are becoming a crucial technological direction in the new energy era. These motors show immense potential in areas like gas turbines, distributed power generation, aerospace, and new energy vehicles.

However, a core challenge arises: as speed increases, the centrifugal force on the rotor grows quadratically.

Taking a surface-mounted permanent magnet motor as an example, when the speed reaches tens of thousands of revolutions per minute, the permanent magnets experience centrifugal forces equivalent to thousands of times their own weight. Traditional metal protective sleeves are either too heavy or lack sufficient strength.

This is where carbon fiber composites demonstrate extraordinary value. With their high strength-to-weight ratio, carbon fiber becomes the ideal "armor" material for high-speed motor rotors.

02 Core Materials

The application of carbon fiber composites in high-speed motors is not a simple material substitution but a carefully engineered system.

Carbon fiber is typically combined with matrix materials like epoxy resin to form Carbon Fiber Reinforced Polymer (CFRP). The elastic modulus and tensile strength of this material are its key performance indicators, directly determining its ability to withstand the immense stress from high-speed rotation.

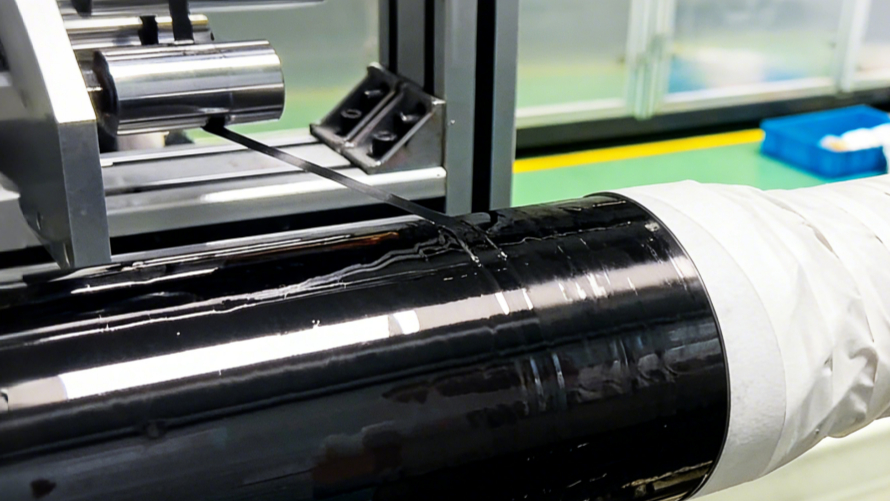

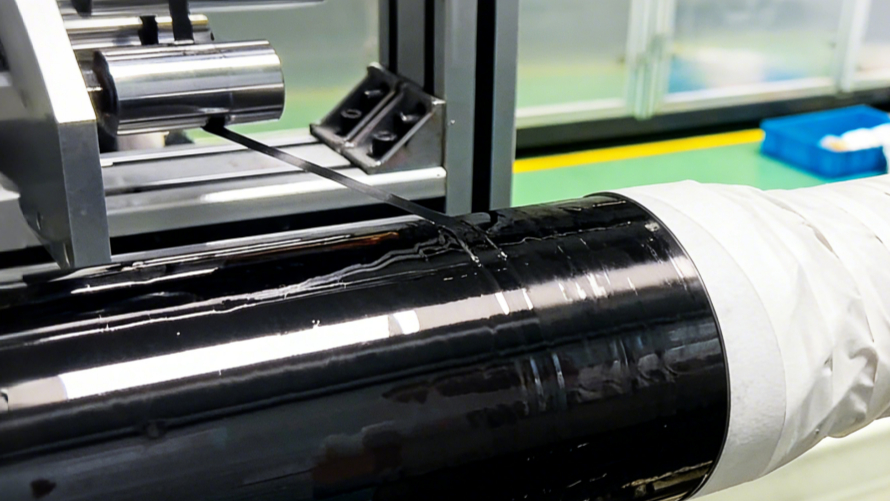

To optimize carbon fiber performance, the prepreg tape dry winding molding technique is often used. This method involves heating and softening pre-impregnated prepreg tape to a viscous state before winding it onto a mandrel. Under the compaction of winding tension, the layers bond together, significantly improving impregnation uniformity and molding precision, thereby enhancing product quality.

03 Unveiling the Wrapping Process

The wrapping process is the key to forming the carbon fiber protective sleeve. Based on application needs and material properties, there are two main wrapping methods:

Wet Wrapping involves immersing carbon fiber bundles in resin and then directly winding them onto a mandrel under controlled tension. It has lower costs but faces challenges like resin flow effects and precision control difficulties.

Dry Wrapping uses pre-impregnated prepreg tape, which is heated and softened before being wound onto the mandrel. This method has more stable resin content and higher quality consistency, making it particularly suitable for high-performance applications.

Research indicates that compared to wet wrapping, dry wrapping improves vessel manufacturing efficiency by 30%, reduces resin content by 20%, and decreases total defect area by 40%.

04 Wrapping Angle and Layer Count

Carbon fiber wrapping on high-speed motor rotors is not a random stacking. The design of the wrapping angle and layer count directly impacts the final product's mechanical properties.

A typical wrapping design often employs a combination of multiple layers at different angles. For instance, a patent for a high-speed motor composite sleeve divides it radially into three layers: inner and outer layers of alkali-free glass fiber cloth, with a middle layer of carbon fiber.

The carbon fiber in the middle layer is further divided into two sub-layers: the inner carbon fiber bundles are wound at ±88° circumferentially, while the outer bundles are wound at ±65° circumferentially. This design aims to balance radial and circumferential stress distribution.

In research on high-speed permanent magnet motors for micro gas turbines, researchers found that when all three carbon fiber layers used 90° circumferential winding, the permanent magnets were in a better state of compression, making it suitable for prototype fabrication.

05 Challenges and Innovations

Carbon fiber wrapping technology for high-speed motor rotors faces several challenges. Material property changes under high-temperature environments are a critical issue.

Modal analysis considering temperature rise in a study on high-speed permanent magnet motors for micro gas turbines showed that the natural frequency of the permanent magnet rotor decreased by over 8.3% in a high-temperature state. High temperatures also cause changes in material properties like elastic modulus, affecting rotor stiffness.

Consistency and precision of the wrapping process is another challenge. Companies like Cygnet Texkimp and Bowman Power are collaborating to develop solutions to improve the speed, accuracy, and repeatability of high-tension winding.

To address tolerance control and surface roughness issues, Tianweilan E-Drive Technology proposed an innovative method: first, spray and cure a gel coat on the inner surface of a mold; then, nest this mold outside the wound rotor body; finally, heat to cure the carbon fiber, allowing it to integrate with the gel coat. This method avoids potential filament breakage issues associated with traditional grinding and polishing processes.

06 Prospects and Applications

Looking ahead, the development trend of carbon fiber wrapping technology in the high-speed motor field is clear. Automation and intelligence levels will further.

Integrating advanced control, sensing, and robotic technologies will not only improve the performance stability and consistency of carbon fiber composite products but also significantly enhance production efficiency and reduce costs.

Carbon fiber wrapping technology has already shown application potential in various fields, including new energy vehicles, aerospace, sports and leisure products, and medical devices. Particularly in the automotive sector, hydrogen storage tanks and high-speed permanent magnet motor rotors are important application directions.

As the demand for high-power-density drive systems in electric vehicles continues to grow, carbon fiber wrapping technology will play an increasingly critical role.

SDM team conducted strength simulations on a high-speed permanent magnet motor with a rated power of 150 kW and a rated speed of 30,000 r/min. Using carbon fiber wrapping technology, they successfully ensured that all rotor components remained within safe strength limits during high-speed rotation.

Engineers meticulously inspect the laying angle and tension control of each carbon fiber layer, much like ancient Roman builders carefully calculating the load-bearing capacity of each stone. However, the centrifugal forces they contend with are thousands of times more powerful than the weight of the stones themselves.

When this motor finally operates at its design speed, each carbon fiber experiences stress variations hundreds of times per second. Yet, they must stand their ground like the Great Wall, protecting the internal permanent magnets and iron core.