Injecting "Steel Reinforcement" into Motors: Demystifying the Precision Potting Process for Frameless Torque Motors

In the field of precision motor manufacturing, an unseen process step is quietly determining the performance ceiling of high-end equipment.

Inside a high-speed rotating frameless torque motor, epoxy resin potting material is precisely injected into the gaps of the stator windings. In a vacuum environment, the resin permeates like a capillary network into the finest grooves, then solidifies under precise temperature control.

In the era of precision manufacturing, exceptional performance often stems from those unseen details—and the potting process for frameless torque motors is precisely such a key procedure, hidden within the motor yet determining overall reliability.

01 Process Fundamentals

What is the potting process? Simply put, it involves filling the motor interior with liquid potting material, which solidifies to form comprehensive protection for the windings. This type of process is not unique to modern times, but it has achieved a qualitative leap in response to the special requirements of frameless torque motors.

Because frameless torque motors omit the traditional motor housing structure, directly exposing the stator and rotor to the host system, their insulation, heat dissipation, and structural fixation all rely on internal materials.

Epoxy resin potting compounds are currently the mainstream choice, capable of withstanding operating temperatures above 180°C, with a thermal conductivity coefficient of 1.0-2.0 W/m·K, making them very suitable for scenarios like stator insulation and waterproofing in new energy motors.

Compared to traditional motor manufacturing processes, the role of potting in frameless motors has been elevated from "auxiliary protection" to "structural support."

Once the special adhesive completely fills the gaps between the stator, rotor, and other components, the originally loose parts are firmly bonded into a single unit. The most direct effect of this structural reinforcement is a significant increase in the motor's mechanical strength, enabling it to withstand greater loads and impacts.

02 Performance Innovation

A single detail can often determine the overall success or failure. The internal structure of frameless torque motors is extremely intricate, and traditional potting methods cannot meet their high-reliability requirements. Engineers need to solve three key technical problems: how to allow the potting material to completely fill the fine spaces, how to prevent bubble generation during the curing process, and how to ensure that the physical properties of the material after curing meet the requirements.

To address these issues, modern potting processes have developed a complete set of solutions.

Data indicates that motors using modern potting processes experience an average reduction in vibration amplitude of 40% and a noise level reduction of over 15 decibels. More importantly, potted motors can achieve the highest IP68 protection rating, allowing stable operation in harsh environments such as humidity, dust, and salt spray.

From a heat dissipation perspective, potting materials typically possess excellent thermal conductivity, enabling rapid conduction of heat generated by the windings to the motor housing.

Compared with traditional air insulation, the thermal resistance of potted motors is reduced by 60%, and the operating temperature drops by 20-30°C. Lower operating temperatures mean slower aging of insulation materials, stable bearing lubrication, and an extension of the motor's overall lifespan by 2-3 times.

03 Material Formulation

The choice of epoxy resin potting material directly impacts the final performance. Research shows that epoxy-based potting compounds can operate at temperatures up to 180°C, remain stable within a range of -40°C to 150°C, and have a curing shrinkage rate below 1%.

Research on slotless brushless torque motors points out that the resin potting process plays a crucial role in motor performance. By analyzing pretreatment temperature, cyclic vacuum treatment, and the curing mechanism of the resin matrix, researchers found that using a pretreatment temperature of 80°C for 40 minutes, combined with 3 cycles of vacuum treatment, yields the best potting results.

The treatment conditions need to be precisely controlled at -0.095 MPa, 85°C, for 20 minutes.

The proportion of toughening agents is another critical point. Experimental results show that when the amounts of non-reactive toughening agent QY and reactive toughening agent DFC are 5g and 15g respectively, adding the non-reactive toughening agent first with a promoter amount of 0.3g, the adhesion, strength, and temperature resistance of the resin system reach an optimal state.

04 Technological Innovation

Advances in potting equipment and processes have revitalized this traditional technique. According to research from the Open University of China, using high thermal conductivity adhesive for overall potting of the motor stator can reduce the thermal resistance between the windings and the stator core, lowering the motor temperature rise by 10–18°C.

The latest patents show that frameless motor stator potting devices have been significantly improved.

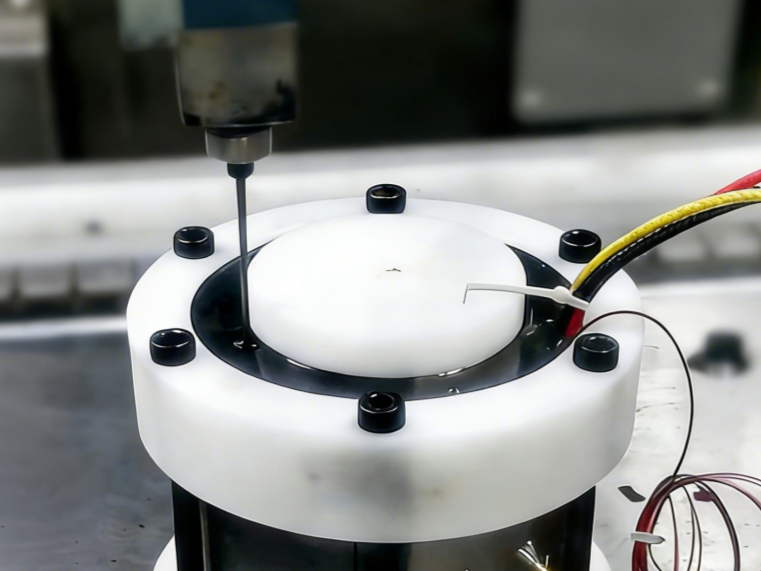

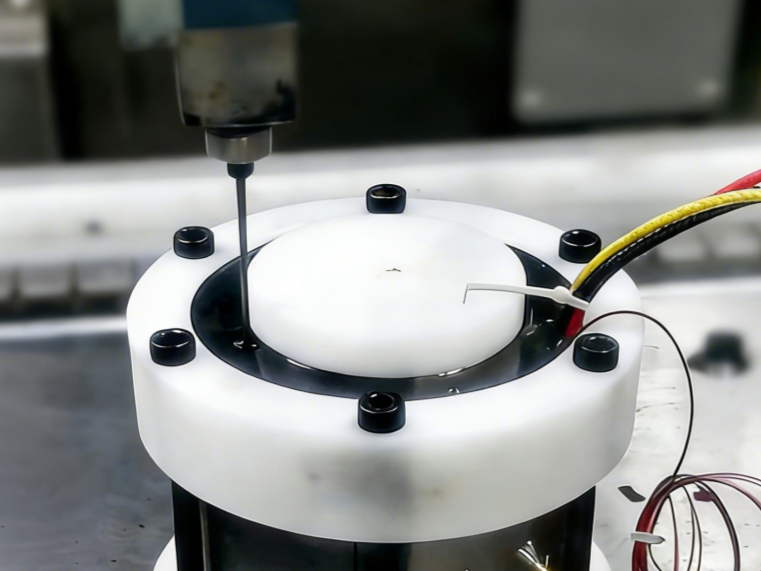

In August 2025, a utility model patent for a "Frameless Motor Stator Potting Device" was granted. This device includes a lower support assembly, an upper pressing assembly, an internal sealing assembly, and a fastening assembly, which can optimize the potting effect for frameless motor stators.

Increased automation has brought dual improvements in manufacturing precision and production efficiency. Modern potting machines, through computer control systems, can precisely adjust adhesive volume, mixing ratio, injection pressure, and curing cycle.

Compared with traditional manual operations, potting machine efficiency increases by 3-5 times, material waste is reduced by 70%, and production costs are significantly lowered.

05 Application Impact

The potting process offers new possibilities for motor design. As the adhesive provides additional structural support and heat dissipation pathways, designers can reduce certain structural components while guaranteeing performance, achieving overall lightweighting.

Miniaturization and lightweighting are of great significance for robots, drones, and precision medical equipment.

Another advantage that cannot be overlooked is electrical stability and reliability. The high insulation strength of potting materials ensures reliable insulation between windings and between windings and the iron core, significantly reducing partial discharge phenomena.

Data shows that the insulation resistance of potted motors can increase by over 50%, and voltage withstand strength can be enhanced by 30%, significantly lowering the risk of electrical faults.

06 Future Trends

Advances in materials science are driving potting technology to higher levels. New potting materials continue to emerge, such as nano-composite adhesives with higher thermal conductivity and elastic adhesives combining flexibility and strength, further expanding the application prospects of potting technology.

In the future, intelligent potting systems will be deeply integrated with motor design software, achieving full-process optimization from design to manufacturing.

More precise simulation analysis capabilities will enable engineers to predict material flow, curing processes, and final performance before potting. This trend towards design-manufacturing integration will significantly shorten R&D cycles, reduce trial-and-error costs, and provide customers with more reliable motor products.

The R&D personnel of SDM even designed special lower support components, internal sealing components and fastening components for the encapsulation adhesive. This equipment ensures that the liquid adhesive can flow precisely in a vacuum environment. Under the precise control of -0.095 MPa, every tiny gap inside the frameless motor is perfectly filled.

When the last drop of potting material solidifies and the motor begins to rotate, those internal details may never be seen by the end-user. Yet, it is precisely these unseen potting processes that support the stable movement of precision robotic arms and ensure the accurate response of drone flight controls.