In the pump room of a chemical plant in Shanghai, a magnetic drive pump equipped with a permanent magnet coupling has been operating continuously for two years without a single leak. Before the retrofit, the mechanically sealed pump required maintenance at least quarterly.

In the world of mechanical equipment, how to connect two rotating shafts to transmit power has always been a critical issue. Mechanical couplings, as the traditional solution, have served industry for over a century. However, a new technology based on magnetic principles—the permanent magnet coupling—is playing an increasingly important role in key fields due to its unique advantages.

The Fundamental Difference Between the Two Types of Couplings

Mechanical Couplings are mechanical components that transmit power through physical connections. Their common characteristic is the need for direct or indirect physical contact. They can be categorized into three main types: rigid couplings (for applications where two shafts can be precisely aligned), flexible couplings (capable of compensating for relative displacement between shafts), and safety couplings (featuring overload protection).

Permanent Magnet Couplings, on the other hand, are a new type of coupling that uses the magnetic force of permanent magnets to connect the prime mover and the driven machine. Their core principle is "non-contact transmission"—utilizing the interaction between rare-earth permanent magnets and the property of magnetic fields to penetrate space and matter to transmit mechanical energy.

Comparison Dimension | Mechanical Coupling | Permanent Magnet Coupling |

Connection Method | Physical contact connection | Non-contact magnetic connection |

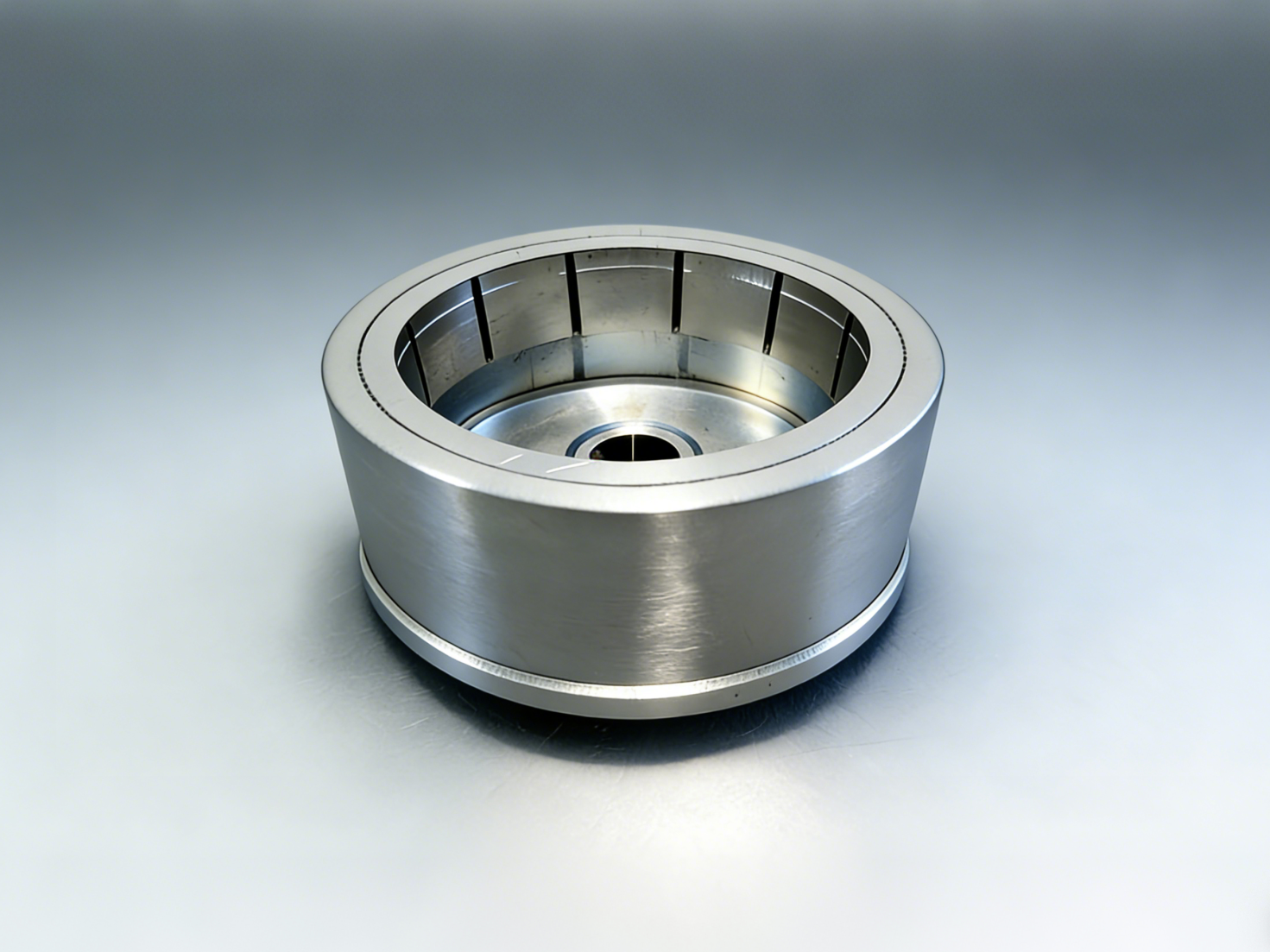

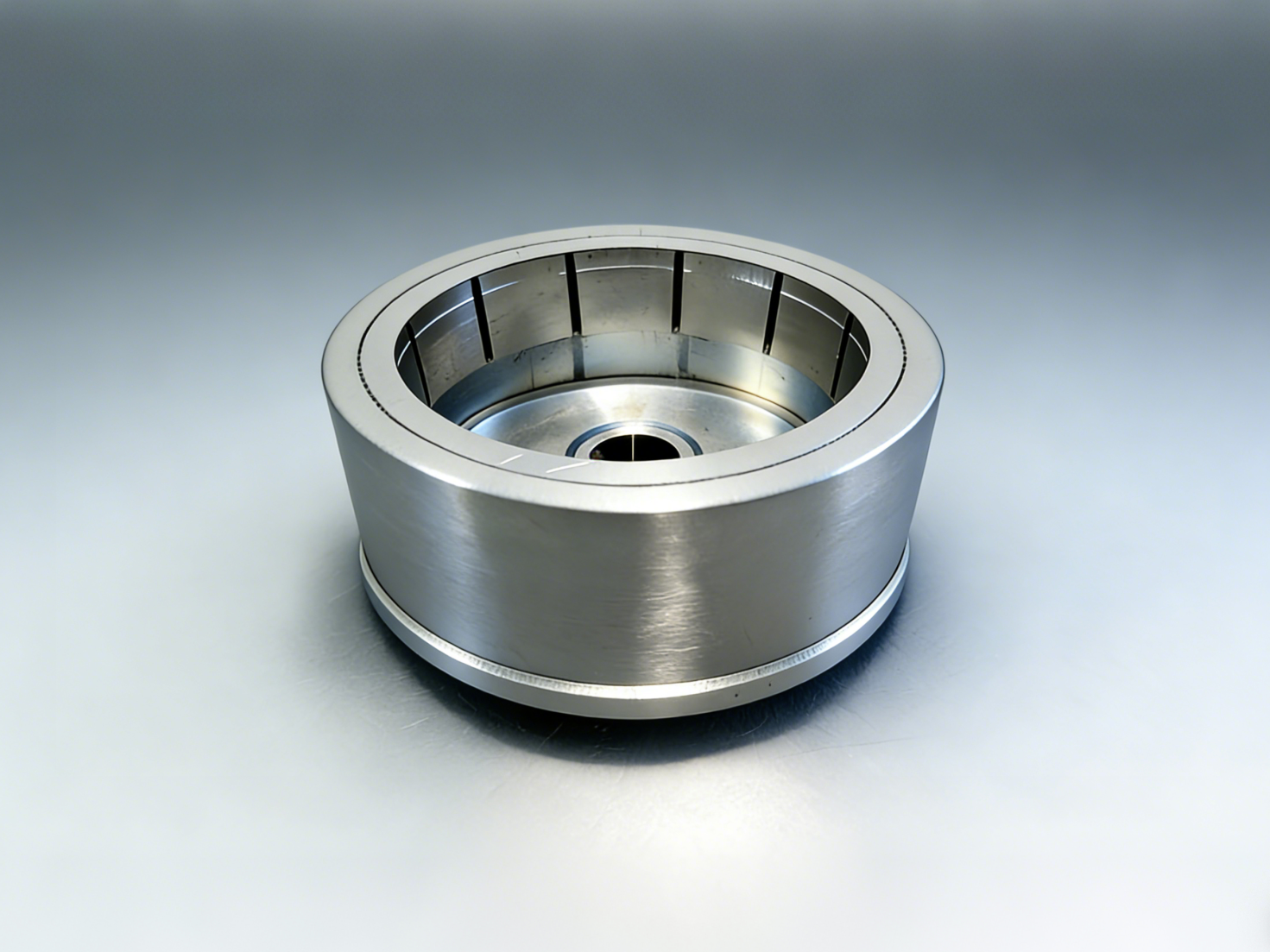

Main Components | Coupling body, bolts, elastic elements, etc. | Outer rotor, inner rotor, containment shell |

Leak Risk | Possible leakage at dynamic seals | Fully sealed, zero leakage |

Compensation Ability | Flexible couplings have limited compensation | Multi-directional compensation (axial, radial, angular) |

Maintenance Needs | Requires regular inspection, lubrication, replacement of worn parts | Maintenance-free, lubrication-free |

Protection Function | Available in some safety couplings | Built-in overload protection |

The Tradition and Limitations of Mechanical Couplings

The mechanical coupling family has many members. For example, gear couplings widely used in heavy machinery can transmit enormous torque and compensate for comprehensive displacement. Meanwhile, simple-structured flexible pin couplings rely on rubber elastic sleeves for cushioning and vibration damping, making them suitable for frequent start-up applications.

However, their common shortcoming lies in "contact" itself. Direct physical contact implies continuous friction and wear, necessitating regular maintenance or part replacement. More importantly, when a coupling needs to transmit power through a sealed barrier (e.g., a pump casing), the rotating shaft must extend out of the casing, creating a "dynamic seal" leakage point that is difficult to eliminate completely. In industries like chemicals, pharmaceuticals, etc., where toxic, hazardous, expensive, or high-purity media are handled, even trace leakage is unacceptable.

How Permanent Magnet Couplings Work

Permanent magnet couplings cleverly solve this problem. Their structure is like a "magnetic sandwich": the driving shaft is connected to an outer rotor equipped with permanent magnets, the driven shaft is connected to an inner rotor also equipped with permanent magnets, and the two are completely separated by a sealed cover called a "containment shell" or "isolation can." The secret of power transmission lies in the attraction and repulsion between the magnetic poles of the permanent magnets on the inner and outer rotors. When the driving end rotates, the magnetic field coupling "drags" the driven end to rotate synchronously.

The containment shell converts a rotating dynamic seal into a stationary static seal, achieving complete isolation of the transmission components, thus fundamentally preventing leakage. Based on the arrangement of the permanent magnets, they are mainly divided into cylindrical and disc types. The cylindrical structure is currently mainstream because it has a large transmission radius, can transmit high torque, and generates very small axial force.

The Transformative Advantages Brought by Magnetic Transmission

Beyond addressing the core pain point of leakage, permanent magnet couplings bring a series of performance improvements.

Cushioning, Vibration Damping, and Protection: The magnetic connection is a natural "soft connection." When the load end suddenly jams, slip can occur between the inner and outer rotors, thereby effectively cushioning impact and protecting the motor and equipment. When the torque exceeds the design limit, the coupling can slip completely, achieving non-destructive overload protection.

Excellent Misalignment Tolerance: Magnetic field coupling allows for a certain degree of axial, radial, and angular misalignment between the inner and outer rotors. This means the requirement for precise shaft alignment during installation is greatly reduced, simplifying installation and accommodating deformation that may occur during equipment operation.

High Efficiency and Energy Saving: Because there is no mechanical contact and wear, its transmission efficiency is extremely high, approaching 100%. Simultaneously, its no-load starting characteristic allows the motor to start smoothly under almost no load, reducing the starting current (by 1/2 to 2/3), which saves energy and extends motor life.

How to Choose: Application Dictates

These two technologies are not in a simple substitution relationship but have their own strengths depending on the application scenario.

Permanent magnet couplings are the preferred choice in the following scenarios:

· Stringent Sealing Requirements: Pumps, agitators, and other equipment handling flammable, explosive, toxic, corrosive, expensive, or high-purity media in industries such as chemicals, petroleum, pharmaceuticals, food, and electroplating.

· Underwater or Vacuum Environments: Such as submersible pumps, vacuum pumps, etc., where their maintenance-free characteristic is highly advantageous.

· High Maintenance Cost or Inconvenient Occasions: Process industries requiring long run cycles and reduced downtime for maintenance.

Areas where mechanical couplings still hold advantages:

· Ultra-heavy-duty, Ultra-high Torque Transmission: In some ultra-high power, ultra-high torque transmission applications, traditional gear couplings may still be a mature and reliable choice.

· Extreme Cost Sensitivity: For general-purpose machinery with no sealing requirements and good operating conditions, mechanical couplings have a significant initial cost advantage.

· Extreme Temperature Environments: The magnetism of permanent magnets decays above certain high temperatures, while some metal mechanical couplings can withstand higher temperatures.

Intelligence and Future Trends

Permanent magnet coupling technology is still evolving. Current research frontiers include optimizing magnetic circuit and pole design to transmit greater torque with less magnetic material. Some advanced products have begun integrating intelligent monitoring systems that can monitor torque, slip, and temperature in real-time, enabling predictive maintenance.

This technology has received national-level recognition. For example, "Large Elastic Same-Displacement Non-Contact Synchronous Permanent Magnet Transmission Technology" has been included in the National Key Energy-Saving and Low-Carbon Technology Promotion Catalog, highlighting its significant potential in energy conservation and emission reduction.

Mechanical couplings continue to support the backbone of industry with their robustness and reliability. Permanent magnet couplings, like a quiet innovator, use invisible lines of magnetic force to transmit efficient and absolutely safe power across those critical sealed boundaries where failure is not an option.

With advancements in materials science and design processes, this dialogue between "contact" and "non-contact" transmission will continue, jointly propelling the mechanical industry toward greater efficiency, reliability, and intelligence.