NdFeB Radiation Ring: A New Generation of Core Technology Leading the Transformation of Magnetic Circuit Design

In the manufacturing workshop of high-end servo motors, engineers carefully adjust the splicing angles of magnet tiles, attempting to eliminate weak magnetic field distortions—a problem that has plagued the industry for decades. Today, this challenge is quietly being solved by a seamless ring.

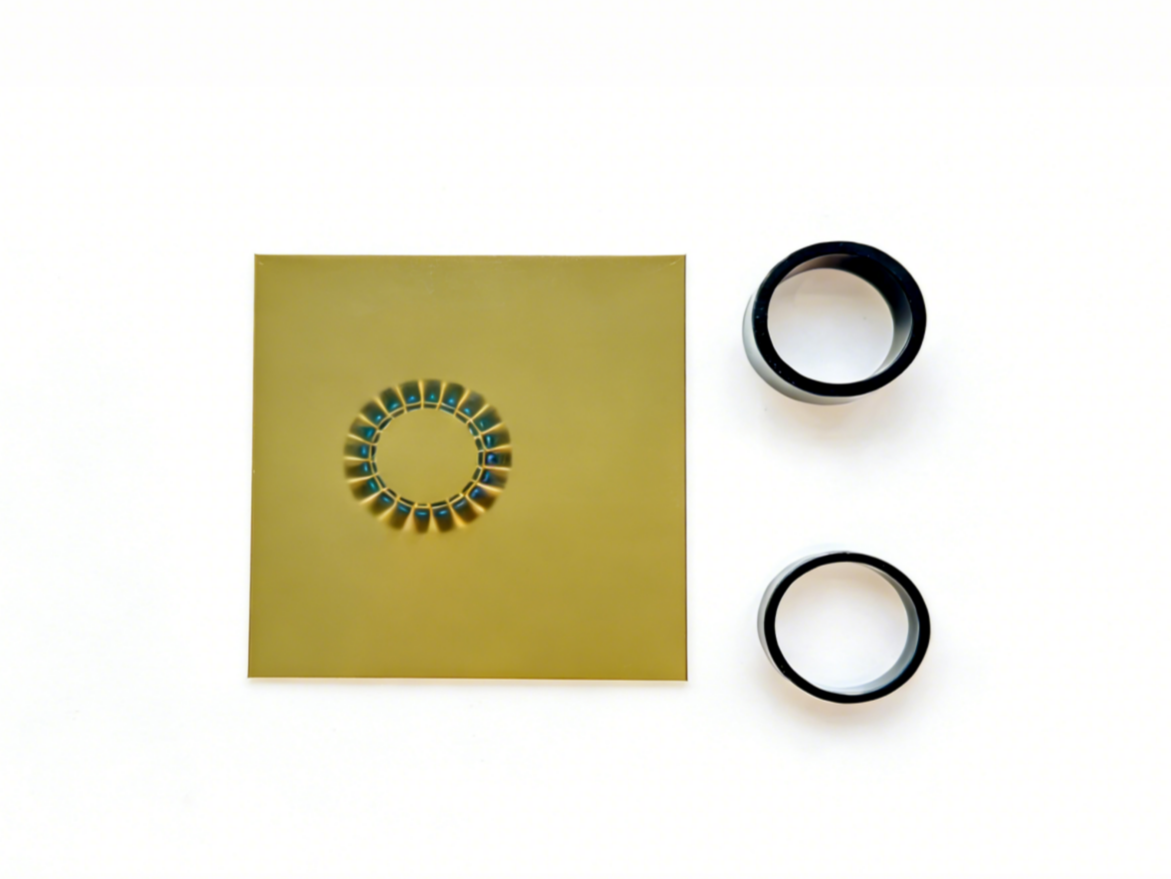

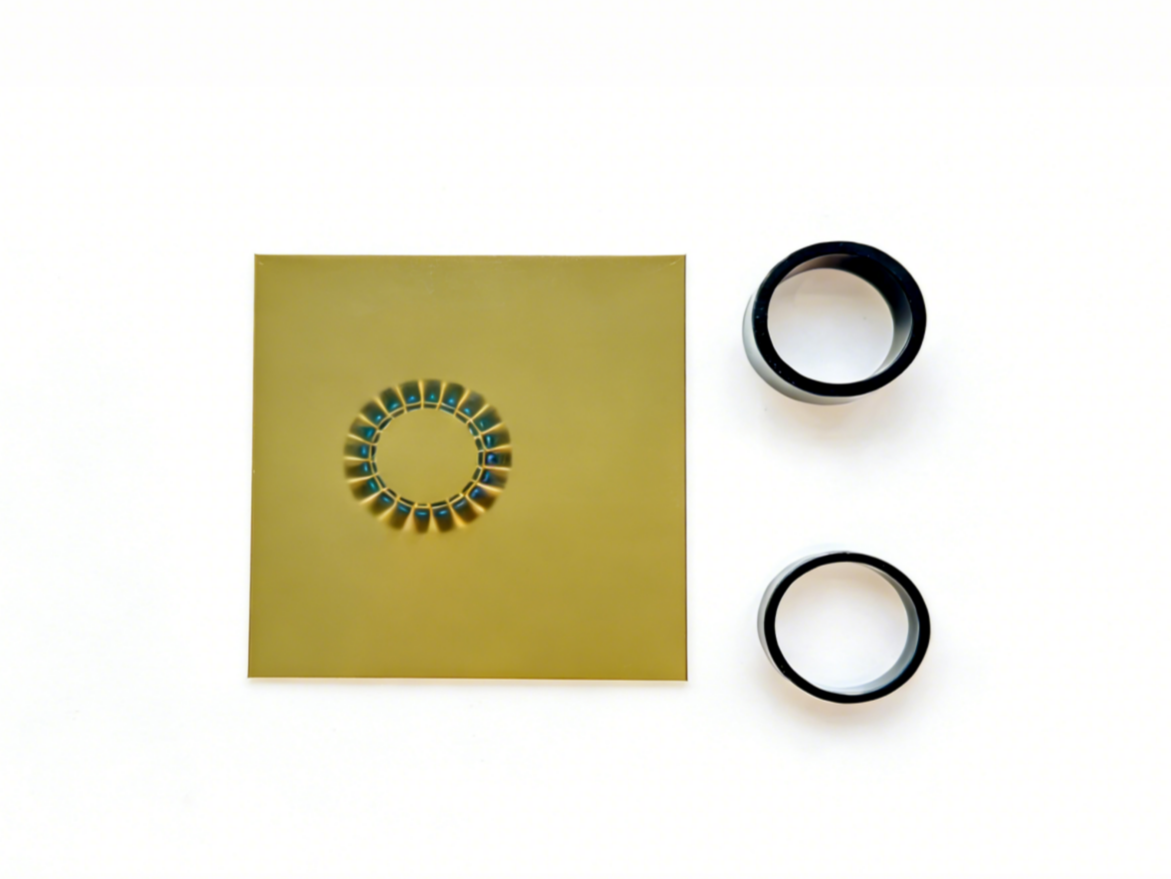

Sintered NdFeB radially oriented magnetic rings are gradually replacing traditional segmented magnet tile splicing solutions. This integrated magnetic ring overcomes the drawbacks of traditional tile-shaped block splicing, such as magnetic loss and difficult assembly.

Unlike traditional spliced magnetic rings, which require a soft magnetic material frame structure to fix the magnet tiles, radiation magnetic rings are a type of specially oriented ring-shaped permanent magnet with a more uniform magnetic field distribution, effectively improving the sinusoidal degree of the motor air gap magnetic field.

01 Background of Technological Upgrade

Traditional permanent magnet brushless motors mostly use magnet tile splicing to form a Ring-shaped magnetic circuit, but this design has obvious flaws. The magnet tile splicing solution requires a soft magnetic material frame structure to fix the tiles, leading to significant magnetic flux loss and greatly affecting the motor power factor and efficiency.

More importantly, spliced magnetic rings suffer from high processing accuracy requirements, difficult assembly, poor smoothness of magnetic pole transitions, and severe motor noise. With the rapid development of artificial intelligence and automation technologies, the market demand for miniaturized, lightweight, and efficient motors continues to expand, making traditional magnet tile splicing technology increasingly inadequate to meet current technical requirements.

This technological Difficult situation has spurred the research and application of a new generation of permanent magnet solutions—NdFeB radiation magnetic rings. Compared to traditional magnet tiles, radiation rings have emerged as the preferred key material component for manufacturing small, high-performance permanent magnet motors and sensors.

02 Core Technology Comparison: Radiation Ring vs. Segmented Magnet Tiles

Radiation rings and traditional segmented magnet tiles differ significantly across multiple dimensions. In terms of structural integrity, radiation magnetic rings are integrally formed, while segmented magnet tiles are assembled from multiple independent magnetic blocks.

In terms of magnetic field uniformity, radiation magnetic rings have a continuous magnetic field distribution with a sinusoidal waveform and small transition zones between magnetic poles, whereas segmented magnet tiles exhibit obvious magnetic field distortions and Local weakness areas.

Assembly complexity is also an important consideration. The assembly process for radiation rings is simplified, eliminating more than ten steps such as magnet tile cutting, positioning, and bonding. In contrast, segmented magnet tiles require complex assembly processes and multiple Processing steps.

From the perspective of structural strength, radiation rings are sintered as a whole, eliminating physical connection weaknesses from splicing or bonding, and they exhibit excellent impact resistance and vibration resistance. In comparison, segmented magnet tiles have physical connection weaknesses.

In terms of cost-effectiveness, although radiation rings have higher initial manufacturing costs, they offer significant advantages in lifecycle costs. Segmented magnet tiles, on the other hand, suffer from long-term cost disadvantages due to complex processes and performance limitations.

Additionally, in terms of motor performance, radiation rings significantly improve the sinusoidal degree of the motor air gap magnetic field, reducing operational noise and vibration. Segmented magnet tiles, however, cause unstable motor operation and higher noise due to magnetic field distortions and gaps between tiles.

03 Technical Classification and Manufacturing Processes

NdFeB radiation magnetic rings can be categorized into several types based on manufacturing methods: bonded NdFeB radiation magnetic rings, hot-extruded NdFeB radiation magnetic rings, and powder metallurgy sintered NdFeB radiation magnetic rings.

The bonding process is relatively mature and inexpensive, so bonded NdFeB radiation rings account for the largest production share. However, bonded magnetic rings have lower density and performance, limiting their development in high-end application scenarios.

In contrast, high-performance sintered and hot-pressed/hot-deformed NdFeB radiation magnetic rings offer higher magnetic performance but face greater technical challenges. Due to significant differences in shrinkage ratios and thermal expansion coefficients between the easy magnetization axis and hard magnetization axis directions of NdFeB grains, these magnetic rings are prone to Fragmentation during preparation, magnetization, and assembly, resulting in low Finished product rates and generally higher prices.

04 Multi-Domain Applications

NdFeB radiation magnetic rings have demonstrated broad application prospects in Multiple high-end fields. In the industrial automation field, radiation rings are particularly suitable for high-speed, high-precision control motors, such as servo motors and industrial robots.

Domestically developed radiation multi-pole magnetic rings have passed pilot tests and are successfully Applied to downstream enterprises' servo motor projects, breaking the long-term dependence on imported servo motors in China. According to tests, motors using such magnetic rings show at least a 10% increase in power compared to traditional magnet tile solutions.

In the sensor technology field, NdFeB magnetic rings also play an important role. Researchers from the Hefei Institutes of Physical Science, Chinese Academy of Sciences, have developed a Faraday rotation spectroscopy sensor based on an NdFeB permanent magnet ring array for detecting gases such as nitric oxide and nitrogen dioxide.

This sensor uses 14 identical NdFeB permanent magnet rings arranged in a non-equidistant form to generate a stable static magnetic field, with an average magnetic field strength reaching 346 Gauss. Compared to traditional electromagnetic coil solutions, this significantly reduces power consumption.

In the automotive and high-end equipment fields, with the advancement of equipment automation, precision, and permanent magnet motor design and manufacturing technologies, high-performance permanent magnet servo motors using sintered NdFeB multi-pole radiation magnetic rings have broad application prospects in automobiles, CNC machine tools, household appliances, computers, robots, and other fields.

05 Technological Challenges and Future Trends

NdFeB radiation ring technology faces multiple challenges, the most prominent being complex preparation technology. NdFeB materials are prone to Fragmentation during preparation, magnetization, and assembly, resulting in low Finished product rates and generally higher prices.

Size limitations are also a significant issue. Hot-pressed radiation rings are mostly thin-walled magnetic rings, with diameters mostly below 30 mm and wall thicknesses below 3 mm. Although sintered radiation rings can be manufactured with outer diameters exceeding 200 mm, they are mostly limited to small-diameter magnetic rings with outer diameters below 100 mm in the market due to Qualified rate and cost constraints.

However, China is catching up in this field. A certain team's research on "A Permanent Magnet Ring Component and Its Preparation Method" has obtained national invention patent authorization.

As the process of sintered NdFeB radiation magnetic rings continues to be optimized and improved, particularly with further development and optimization of orientation magnetic field design and orientation methods, this technology is expected to achieve greater breakthroughs in the coming years.

SDM radiation ring products have been widely used in high-performance permanent magnet motors, precision sensors, and other fields with high requirements for magnetic field stability.