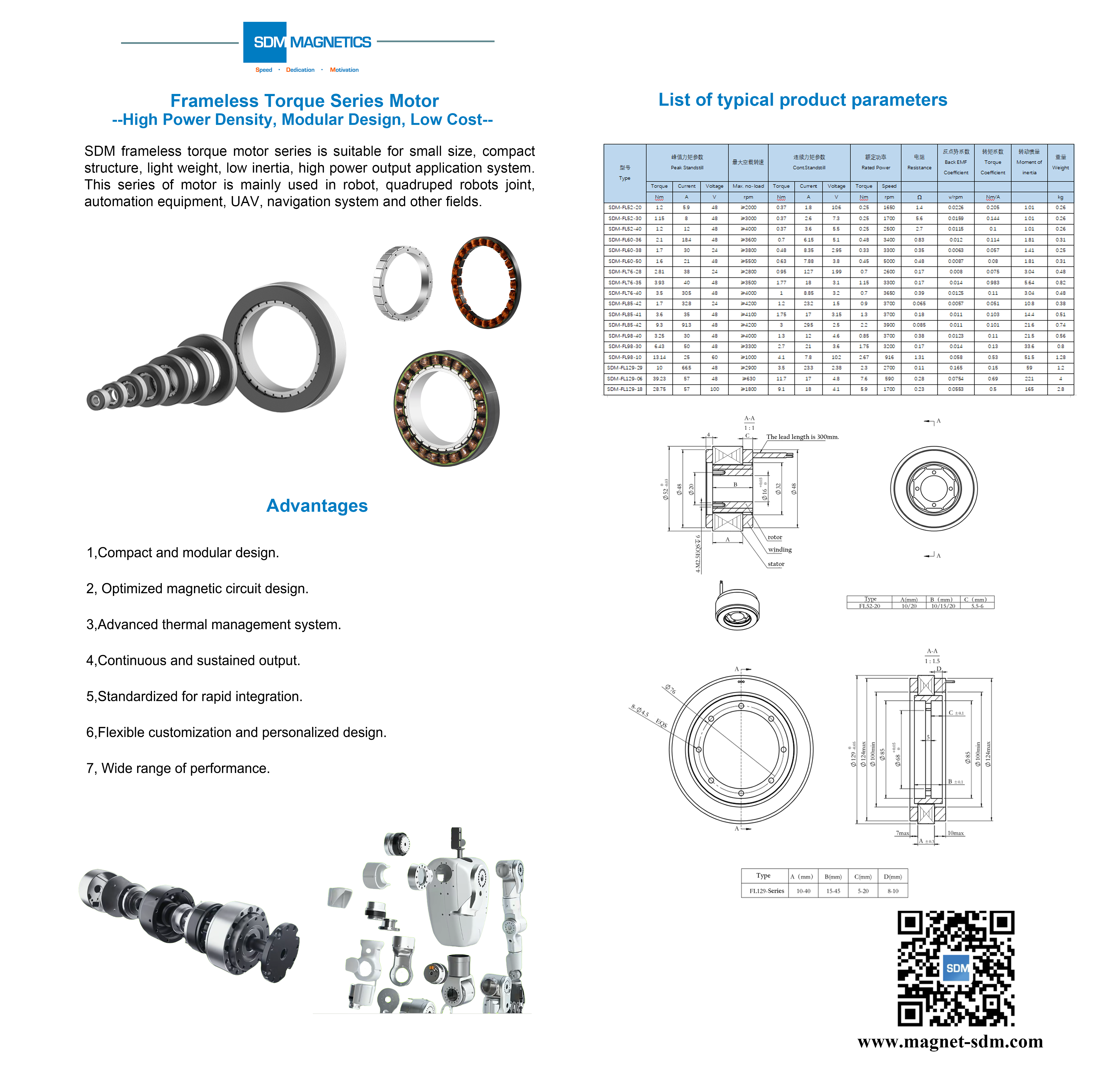

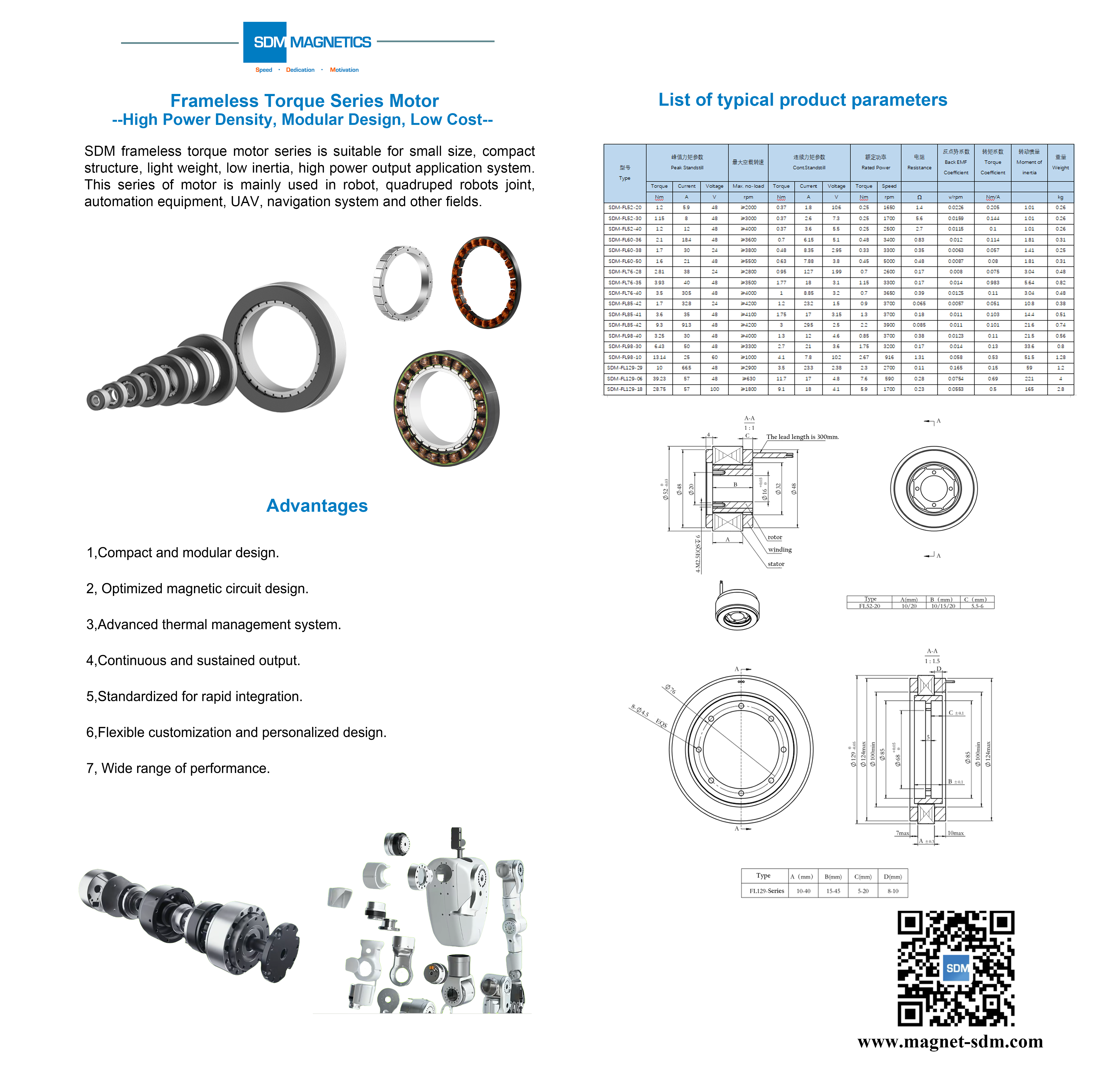

The SDM frameless torque series motors are mainly applied in fields such as robots, robot dogs' joints, automated equipment, unmanned aircraft, and navigation systems. They offer several distinctive features and advantages:

1. Compact & Modular Design

Our motors feature a space-saving electromagnetic package with a low-profile design, supporting seven frame sizes and three winding options. This makes direct integration into mechanical assemblies simple and efficient. The design boosts torque density while ensuring structural rigidity and thermo-mechanical stability — perfect for continuous, long-duty operations.

2. Advanced Magnetic Circuit Optimization

Built with premium electrical steel laminations and high-grade NdFeB magnets (58SH, 54UH, and more), with optional Halbach array designs. Combined with multiple standard winding configurations, this guarantees highly efficient, stable torque delivery across the full speed range.

3. Intelligent Thermal Management

Engineered to handle thermal loads from continuous operation, keeping winding temperatures reliably below 155 °C — ensuring long life and dependable performance.

4. High Continuous Torque Output

Purpose-built for extended duty cycles, delivering exceptional continuous torque for reliable operation in demanding applications such as robotics, machine tools, and industrial automation.

5. Fast & Easy Integration

A wide selection of frame sizes and winding combinations allows flexible system design and seamless integration into existing mechanical and control architectures.

6. Flexible Customization Options

From standard configurations to fully customized solutions, we enable engineers to specify windings, mechanical interfaces, lead lengths, and more — with multiple core lengths available for each frame size — to achieve the perfect system match.

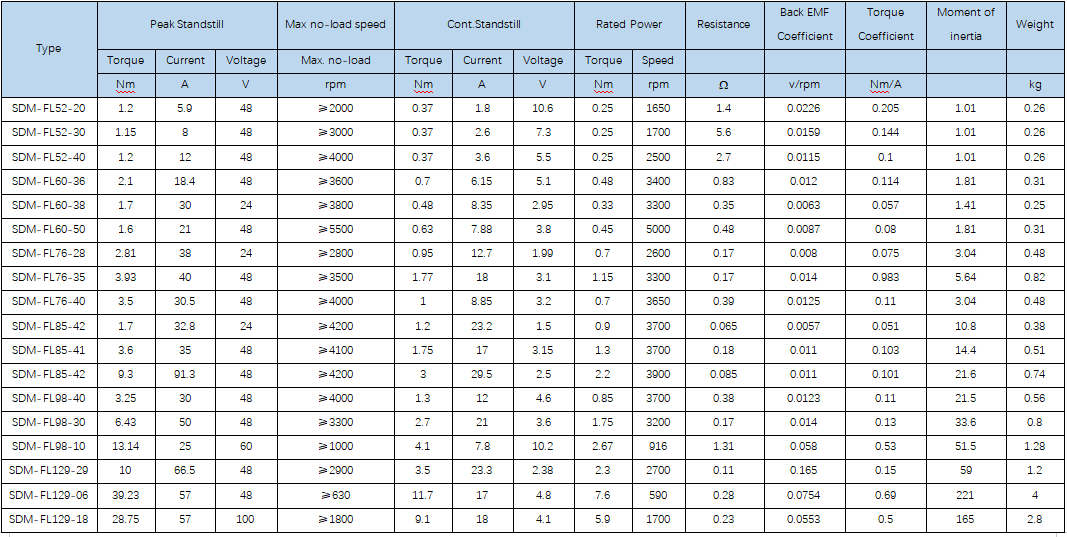

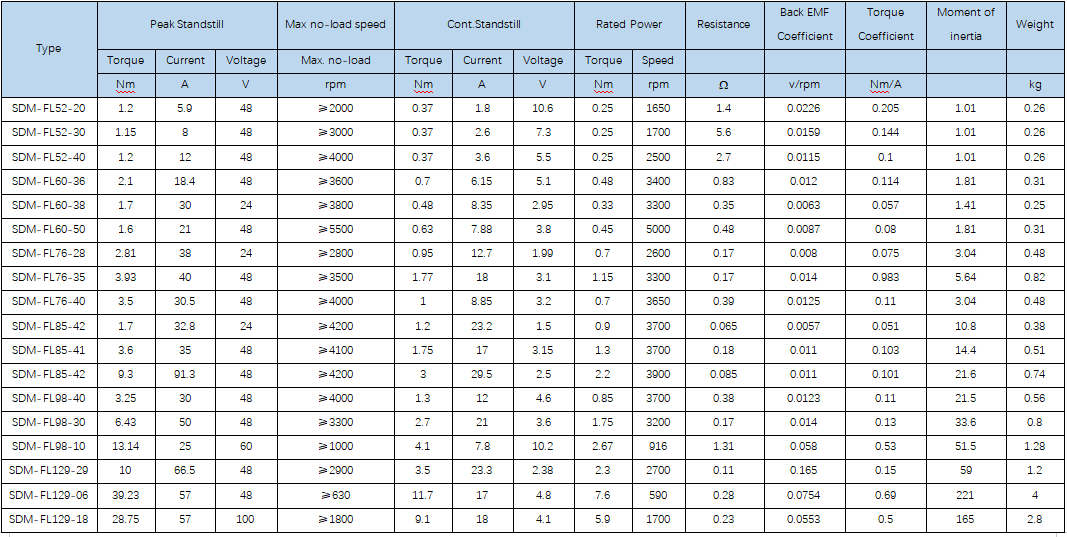

7. Typical Performance Range

Rated power: 700 W – 1500 W

Rated voltage: 24 V – 100 V (48 V common)

Peak torque: 1 Nm – 40 Nm