In a modern factory, a worker inspects a set of completely sealed mixing equipment. Without any mechanical connections, it still transmits power precisely—this is the magic of magnetic couplings at work.

In traditional mechanical transmission, a coupling is a component that connects two shafts to make them rotate together. However, conventional mechanical couplings require direct contact between the driving and driven shafts to transmit torque.

This mechanical connection method has drawbacks such as complex structure, high manufacturing precision requirements, and susceptibility to component damage under overload, especially in applications requiring the isolation of different media, where it faces significant challenges.

The emergence of magnetic couplings has completely changed this landscape. Utilizing a novel magnetic coupling principle, it enables the transmission of force and torque between the driving and driven shafts without direct contact, converting dynamic seals into static seals and achieving zero leakage.

01 The Magic of Magnetism: How Do Magnetic Couplings Work?

A magnetic coupling is a non-contact mechanical device used to connect two shafts and enable rotational transmission. It utilizes the interaction of magnetic fields to transmit torque and motion through magnetic force, eliminating the need for traditional mechanical connecting elements like gears or couplings.

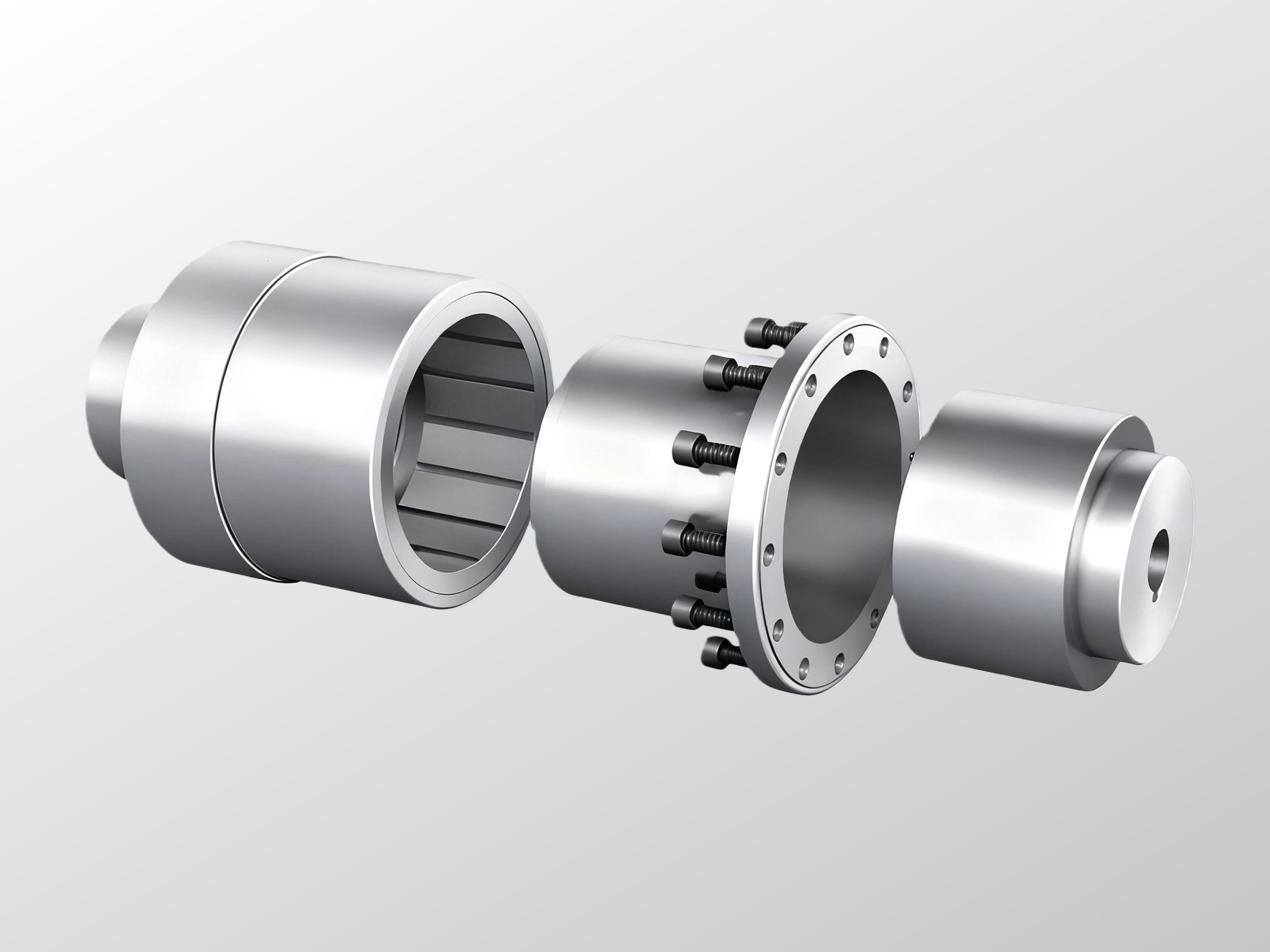

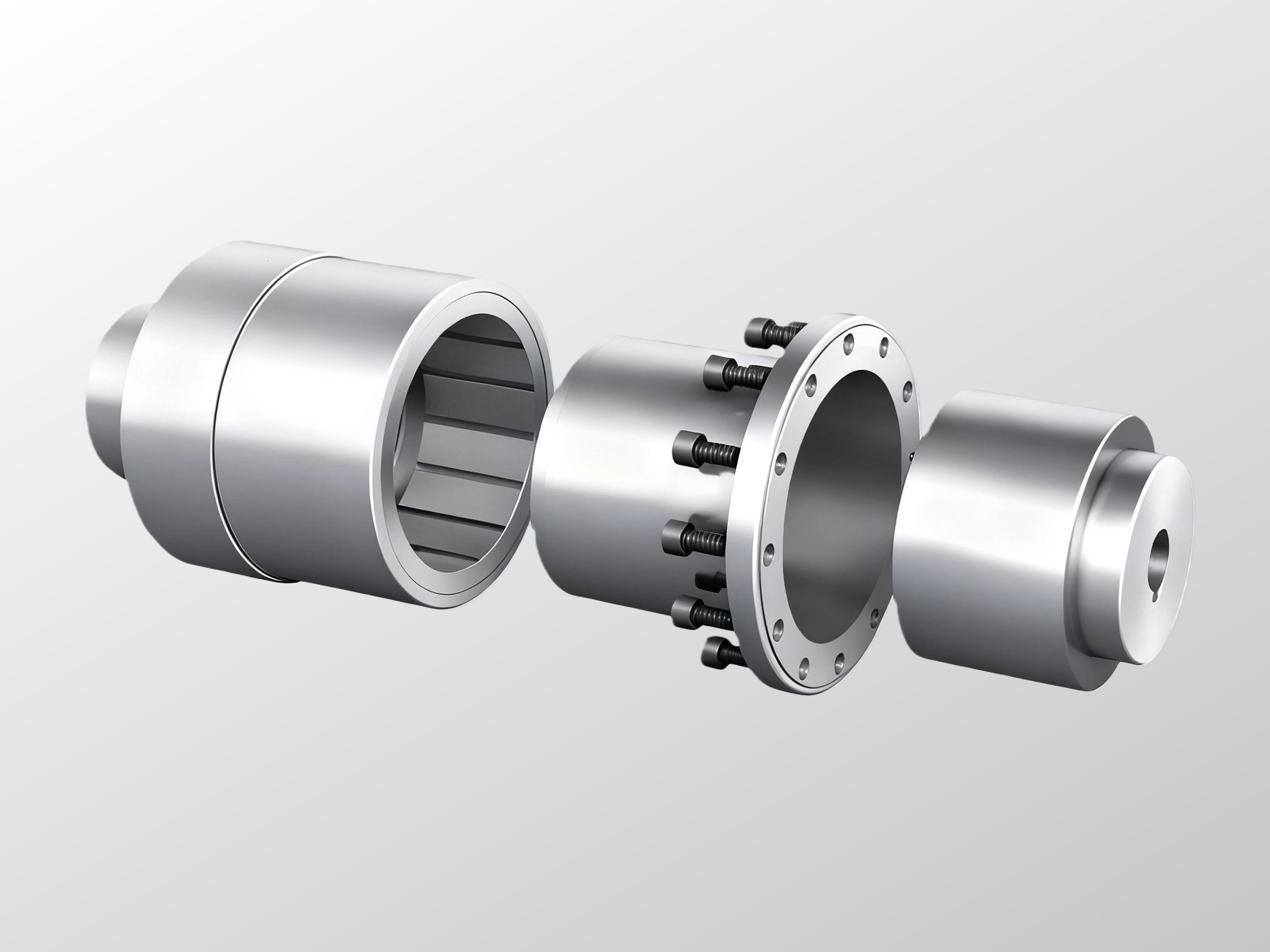

In terms of basic structure, a magnetic coupling consists of an outer rotor, an inner rotor, and a containment shell.

The outer rotor is mounted on the power input shaft and contains a ring of high-strength permanent magnets. The inner rotor is mounted on the load-end shaft, with its magnetic poles corresponding to those of the outer rotor. The containment shell is placed between the two rotors, providing sealing and isolation, and is typically made of non-magnetic material.

Its working principle is: when the outer rotor rotates, its magnetic field rotates accordingly. This magnetic field penetrates the containment shell and interacts (attracts or repels) with the magnets on the inner rotor. This magnetic force drives the inner rotor to rotate synchronously, achieving torque transmission.

Because there is no mechanical contact between the two rotors, power can be transmitted in a sealed state.

Magnetic couplings primarily come in two configurations: ****Face-type Magnetic Drive Couplings and Coaxial Magnetic Drive Couplings.

When magnets are axially magnetized and the coupled poles are arranged axially, it's called a face-type magnetic drive coupling. When magnets are radially magnetized and the coupled poles are arranged radially, it's called a coaxial magnetic drive coupling.

02 Development History: The Evolution of Permanent Magnet Materials

The development of magnetic drive couplings is closely related to the continuous emergence of new permanent magnet materials.

The earliest materials used were ferrites, which had wide source availability and low cost. However, due to their relatively poor magnetic properties, they could only transmit limited torque for a given size compared to traditional couplings, thus restricting the development of magnetic couplings.

The second generation of permanent magnet materials includes Samarium Cobalt (SmCo) and Alnico. Their magnetic properties were significantly improved over ferrites, allowing the manufactured magnetic couplings to transmit greater torque.

However, the Samarium, Cobalt, and Nickel used in SmCo and Alnico are scarce resources, belonging to rare and expensive strategic materials, making them costly and also constraining the development of magnetic couplings.

Rare-earth Neodymium Iron Boron (NdFeB) permanent magnet material became the third generation of permanent magnet materials following SmCo and Alnico.

NdFeB not only has superior magnetic properties but also benefits from abundant raw material resources – using inexpensive iron to replace cobalt and abundant neodymium to replace samarium. Consequently, its price is relatively lower, making it highly competitive in the market and easier to promote and apply.

Furthermore, NdFeB has high magnetic energy product, requires less material, offers good machinability (can be cut and drilled), and has high production yield. This enables the reduction of magnetic coupling size, lowering costs, improving efficiency, and saving energy. It is now widely used in magnetic drive couplings.

03 Performance Advantages: Why Choose Magnetic Couplings?

Compared to traditional couplings, magnetic couplings offer several distinct advantages:

Non-Contact Transmission: Magnetic couplings transmit torque using magnetic field interactions, without the need for direct shaft contact, avoiding wear and friction losses present in traditional couplings. This non-contact transmission method combines non-contact drive with high resilience, significantly reducing impact and vibration in the drive train.

High Transmission Efficiency: Due to the absence of friction losses, magnetic couplings have high transmission efficiency and high energy conversion rates, reducing energy waste. The transmission efficiency of permanent magnet couplings is close to 100%, with no temperature rise.

Cushioning and Protection: Magnetic couplings possess overload protection functionality. Under overload conditions, the magnetic force slips, protecting the equipment. Permanent magnet couplings combine non-contact transmission and high resilience, greatly reducing impact and vibration in the drive train.

No Lubrication Required: As there are no directly contacting parts, magnetic couplings do not require lubricants, reducing maintenance and upkeep efforts.

Complete Sealing: Magnetic couplings are suitable for toxic, corrosive, or high-purity environments. They can convert dynamic seals into static seals, achieving zero leakage.

Allowance for Misalignment: Permanent magnet couplings allow for misalignment on the millimeter scale, reducing installation precision requirements.

04 Application Fields: The Ubiquitous Nature of Magnetic Drive

Magnetic couplings have a wide range of applications across many fields, primarily evident in the following areas:

Chemical, Pharmaceutical, and Food Industries: In mixing equipment within these industries, magnetic couplings provide a completely sealed transmission solution, suitable for toxic, corrosive, or high-purity environments. They effectively prevent media leakage, ensuring production environment safety.

Vacuum Systems and Clean Production Lines: The non-contact, zero-leakage characteristics of magnetic couplings make them irreplaceable in vacuum systems and clean production lines.

Submersible Pumps, Submerged Mixers: In this equipment, magnetic couplings enable the transition from dynamic to static seals,completely solve the leakage problem.

Tension Control in Unwinding and Rewinding Processes: Magnetic particle couplings enable precise, noiseless torque transmission proportional to the excitation current, suitable for tension control in unwinding/rewinding processes and for use on test stands.

Petrochemical Industry: One successful application of magnetic drive couplings is their combination with pumps – magnetic drive pumps. Previously chosen only as expensive special products when absolutely necessary, their application range is now very broad.

05 Innovation Frontier: The Future Development of Magnetic Couplings

With industrial development, magnetic coupling technology is also constantly innovating. Here are some noteworthy development directions:

Heat Dissipation in High-Power Applications: Addressing the significant eddy current heat generated during the operation of high-power magnetic couplers, the industry has developed multi-medium collaborative cooling solutions to overcome the inefficiency of single cooling methods.

This solution achieves efficient cooling through a three-layer structure: "liquid cooling as the primary method, air cooling as secondary, supplemented by heat radiation."

Lightweight Design Trend: As industrial equipment moves towards miniaturization and integration, magnetic couplers are following a lightweight design trend to adapt to compact space requirements.

In material selection, "high-strength lightweight alloys" are used; in structural design, "modular integrated design" is adopted; in connection methods, "quick-connect interfaces" are being developed.

Intelligent Monitoring and Maintenance: For magnetic equipment that remains idle for long periods, reasonable maintenance strategies are necessary. Regularly check the status of idle equipment every 3 months: inspect the equipment exterior for rust or deformation, and check for magnetic strength decay in the magnetic core.

Advances in Materials Science: The invention and development of magnetic drive couplings are closely tied to the continuous emergence of new permanent magnet materials. From ferrites to SmCo to NdFeB, each new generation of materials has driven leaps in performance and expansion in the application range of magnetic couplings.

From robotic arms in vacuum environments to filling equipment in sterile workshops, and even auxiliary systems in your car, magnetic couplings are quietly changing the way power is transmitted.

It's like an invisible hand, transferring force between two isolated worlds without leaving any physical trace.

This silent transmission revolution has only just begun.