Behind modern industrial production, there's a magical device using magnetic force for separation, quietly driving the development of various industries.

In grinding processes, as machining accuracy improves, high-speed grinding and powerful grinding technologies are rapidly developing. Beyond selecting reasonable grinding parameters, it's also essential to enhance the cycle quality of the grinding fluid. As a crucial part of the purification system, magnetic separators play an irreplaceable role.

01 What is a Magnetic Separator?

A magnetic separator is a versatile separation device, primarily used for purifying coolant (cutting oil or emulsion) in grinding machines and other machine tools.

It works by using the magnetic drum of the separator to suck out iron chips from the coolant, keeping the coolant clean.

This equipment can reduce the frequency of wheel dressing, improve the surface smoothness of workpieces, and extend the service life of both the grinding wheel and the coolant.

In industrial production, purification devices are divided into two types: filtration type and dynamic type. Filtration type relies on filter media to remove impurities, such as screen filters, edge-type filters, cartridge filters, and paper band filters.

Dynamic type separates impurities using a specific force, such as centrifugal separators, vortex separators, and magnetic separators.

02 How Does a Magnetic Separator Work?

Magnetic separators are structurally divided into two forms (I, II), each with different working principles.

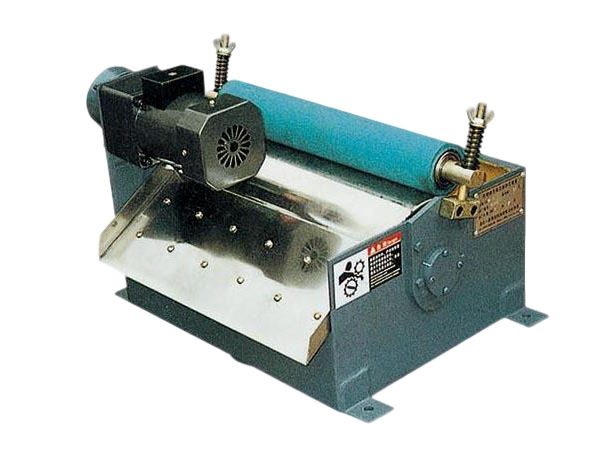

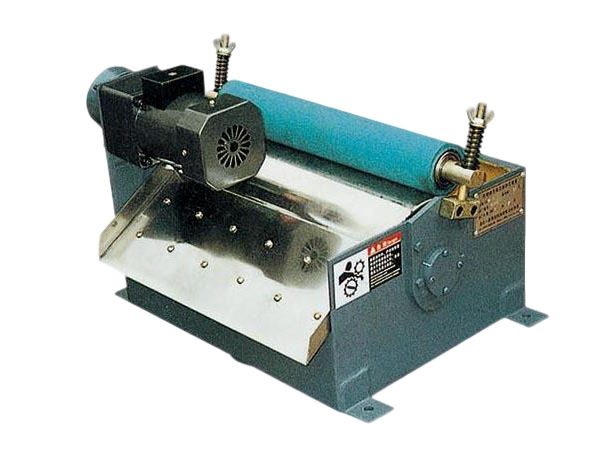

Type I (Rubber Roller Type) Series

The Type I (Rubber Roller Type) series magnetic separator consists of several parts including a gear motor, housing, magnetic roller, and rubber roller.

The gear motor drives the magnetic roller in rotary motion. When coolant containing powdered magnetic impurities enters the housing, the impurities are adsorbed onto the outer wall of the magnetic roller. They are then squeezed by the rubber roller to press out the liquid carried within the impurities.

Finally, a scraper plate separates the impurities from the magnetic roller.

This type of separator is widely used in applications involving coolant purification with powdered impurities, such as surface grinders, internal and external cylindrical grinders, and centerless grinders.

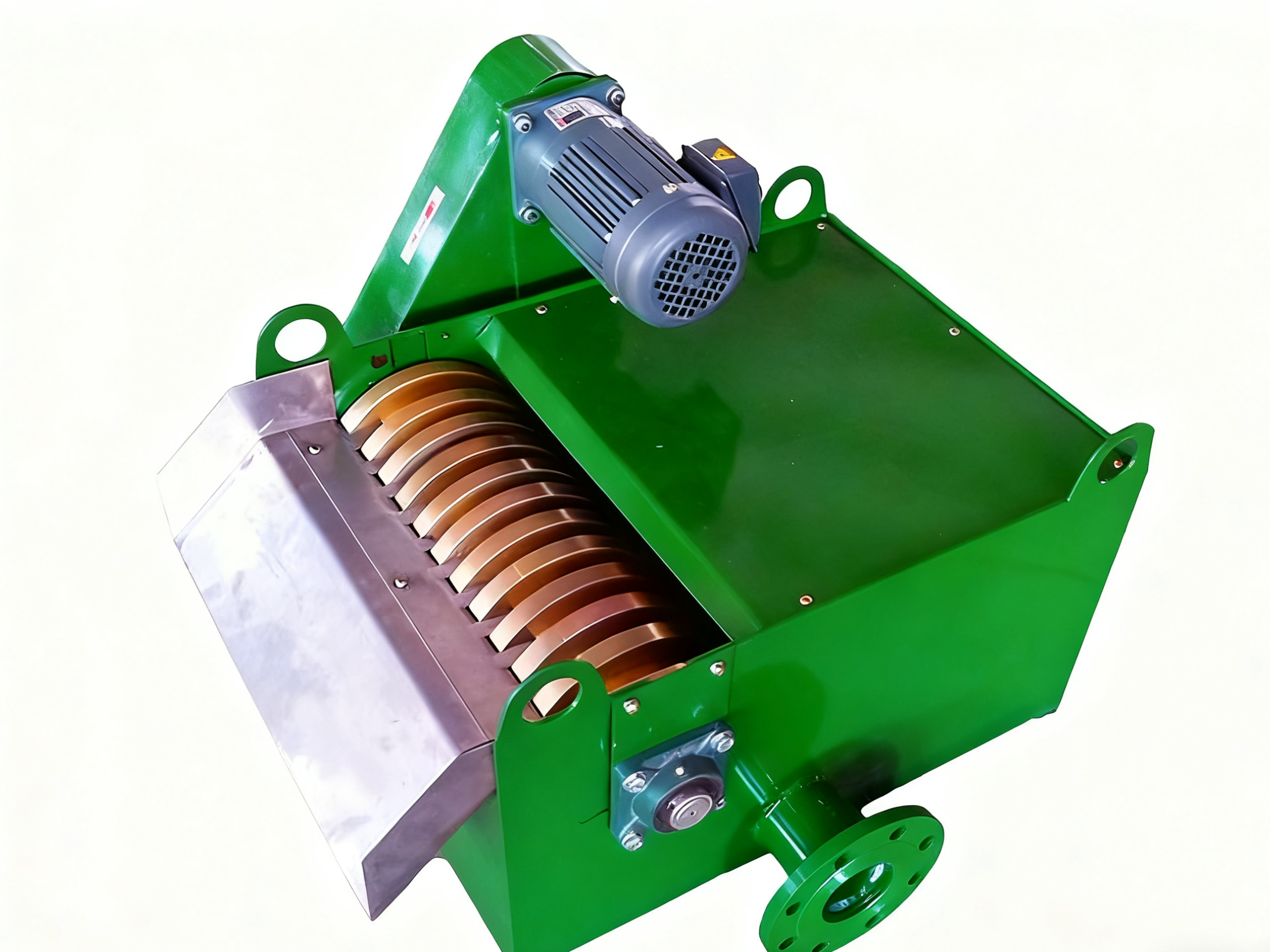

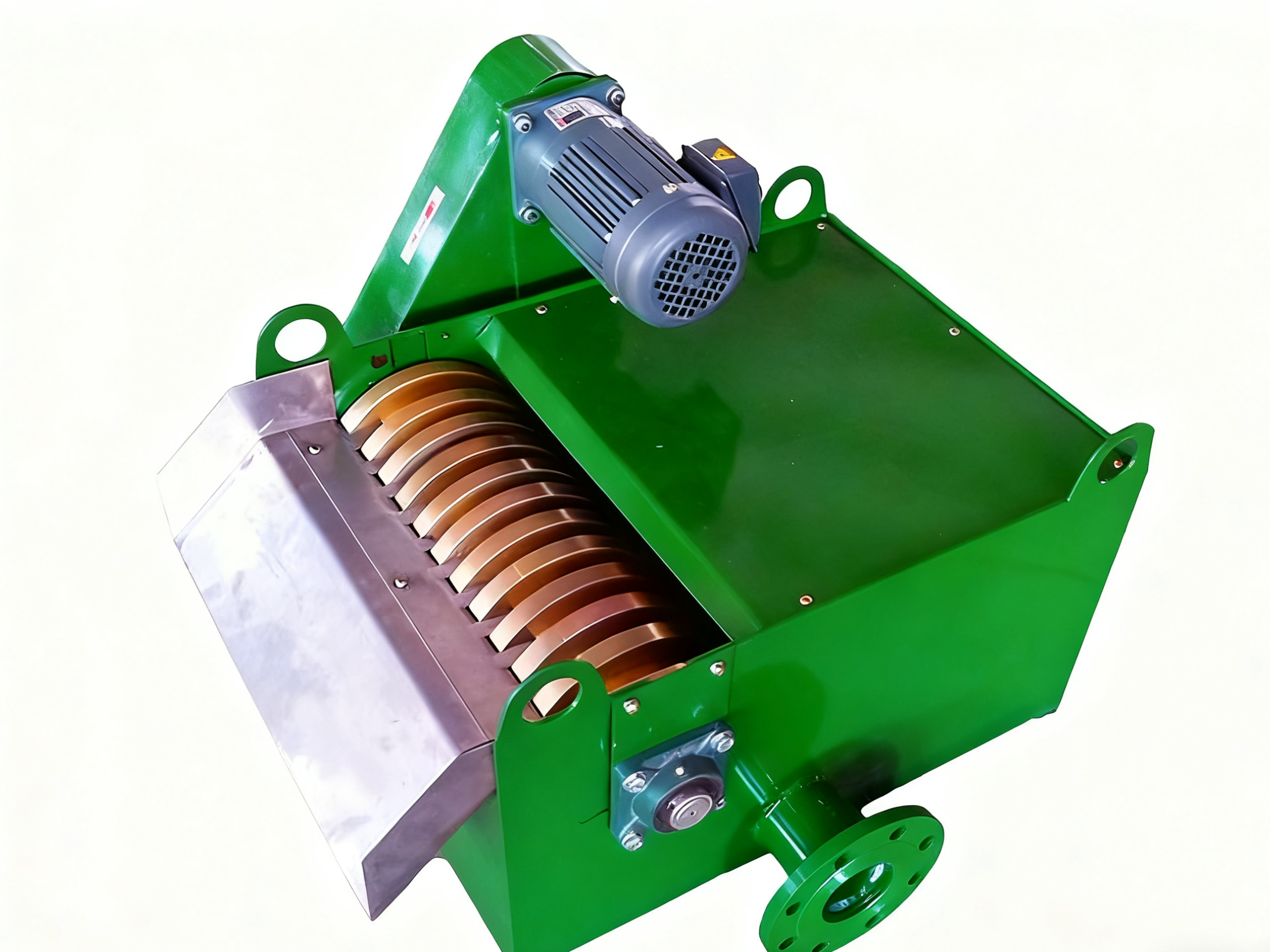

Type II (Comb Type) Series

The Type II (Comb Type) series magnetic separator consists of a gear motor, housing, magnetic roller, and scraper plate.

As an improved version of the traditional magnetic separator, the comb-type magnetic separator has many advantages: forming the magnetic roller of the same length into a comb shape greatly increases the adsorption area; it has strong magnetic force and high separation efficiency.

It is particularly suitable for the centralized separation and removal of large-flow coolant and can separate granular chips.

This separator is widely used in: various ordinary grinding machines, powder coating lines, roll grinding machines, steel rolling wastewater purification, bearing grinding lines, and other occasions involving coolant purification with granular impurities.

03 What are the Application Areas of Magnetic Separators?

Magnetic separators have a very wide range of applications, covering multiple industrial fields.

They are particularly suitable for coolant purification in various grinding machines, precision lapping machines, wire drawing machines, electrical discharge machining (EDM) equipment, as well as grinding machines and other precision machining machine tools.

Most applications involve separation from scrap material. The primary market for magnetic separators is scrap separation in mechanical processing like lathes, grinders, planers.

With the increasing use of aluminum in the market, the volume of aluminum chips inevitably grows larger. The presence of iron makes it impossible to use aluminum scrap rationally, necessitating the use of magnetic separators for separation.

There is also significant need in the production of copper powder and non-ferrous metals.

04 High Gradient Magnetic Separation Technology

High Gradient Magnetic Separation (HGMS) technology is an advanced form of magnetic separator that enhances separation capability by increasing the magnetic field gradient.

Basic Principle

A high gradient magnetic separator consists of yoke iron, electromagnetic coils, and a separation vessel filled with stainless steel wool.

When energized, the electromagnetic coils generate a magnetic field. Particulates in the wastewater flowing through the separator experience magnetic forces within this field and are captured by the matrix – the steel wool.

The stronger the magnetic force, the greater the likelihood of capturing the particulates.

Main Advantages

High gradient magnetic separators can separate weakly magnetic fine particles with low magnetic susceptibility and small size that general magnetic separators cannot handle.

The fibrous stainless steel wool matrix has high magnetization intensity, many sharp edges, small diameter, and low packing density (4-6%), allowing gradients as high as 1000 Gauss/micron.

In water treatment processes, hydrodynamic drag force has the greatest influence. Under certain water quality conditions, the hydrodynamic drag force mainly depends on the flow velocity; the higher the velocity, the easier it is for particles to be washed away.

However, in high gradient magnetic separators, particles can still be effectively separated at flow rates tens or even hundreds of times higher than those used in general sedimentation and filtration methods.

This is one of the main advantages of high gradient magnetic separation.

05 The Contribution of Magnetic Separators in the Environmental Protection Field

Magnetic separators also play an important role in environmental protection, especially in the field of wastewater treatment.

Application in Wastewater Treatment

High gradient magnetic separation technology, used for treating magnetic substances in wastewater, offers advantages such as simple process, compact equipment, high efficiency, fast speed, and low cost.

Ferromagnetic and paramagnetic pollutants in wastewater, such as iron, manganese, cobalt, nickel, chromium metal oxides, can be directly separated by the magnetic separator.

Weakly magnetic or diamagnetic pollutants, however, must form magnetic flocs by seeding with magnetic seeds and adding coagulants, enabling them to be captured by the matrix and separated.

Treatment Effectiveness

Electromagnetic high gradient magnetic separators can effectively treat blast furnace gas wash wastewater containing ferromagnetic and paramagnetic suspended solids.

Under conditions of magnetic field strength and flow velocity of 5 kilogauss and 1.3 m/min or 10 kilogauss and 3.4 m/min respectively, the removal rate of suspended solids exceeds 99%.

A high-magnetic treatment system with a daily capacity of 57,000 m³, operating under specific conditions, can reduce the effluent suspended solids concentration to 5-15 mg/L.

06 Future Development Directions of Magnetic Separators

With technological advancements, magnetic separators are continuously improving and evolving.

Superconducting magnetic separators consume less electricity, and the magnet volume is much smaller than conventional magnets with the same magnetic field strength and effective aperture, which has attracted great interest, but they are still in the experimental research stage.

The development direction for electromagnetic high gradient magnetic separators involves research on the separation, regeneration, and recycling technology of magnetic seeds; and studying reasonable treatment systems and processes to reduce power consumption and improve treatment efficiency.

With the improvement of magnetic material performance, new generation drum magnetic separators can already capture μm-level iron powder, showing greater value in high-end fields like lithium battery raw materials and electronic-grade silicon materials. From manufacturing to environmental protection, from laboratories to large-scale industries, magnetic separation technology is providing clean production solutions for various sectors with its unique charm.

In the future, as new technologies like superconducting magnetic separators mature, this silent magnetic revolution will continue to deepen.