From enabling industrial production to assisting daily life, robots with different forms and functions are bringing earth-shaking changes to people's various economic and social activities. In the future, with the further maturity of cutting-edge technologies such as artificial intelligence, robots will accelerate the development of iteration in technology, promote and spread in application, and increasingly become an indispensable part of human society.

The scale of application continues to expand

According to the 2023 World Robot Report released by the International Federation of Robotics, global industrial robot sales reached 553,000 units in 2022, an increase of 5% year-on-year and a record high. The cumulative number of industrial robots in operation worldwide is about 3.9 million, an increase of 12% year-on-year. Between 2017 and 2022, global industrial robot sales will grow at a compound annual growth rate of about 7%.

The report shows that the sales of industrial robots in Asia Pacific, Europe and the Americas have shown growth, of which Asia Pacific continues to become the world's largest industrial robot market, and its market share continues to rise. 73% of global industrial robot sales in 2022 will be concentrated in the Asia-Pacific region.

The report pointed out that in 2022, the electronics and electrical industry will have the highest demand for industrial robots, reaching 157,000 units, an increase of 9.8%. Automobile industry demand reached 136,000 units, an increase of 16.2%. Strong demand in both industries has driven a significant increase in industrial robot sales.

Artificial intelligence and machine learning are increasingly applied in the robot industry, especially generative artificial intelligence technology provides a new solution for robot programming, so that non-professionals can freely operate robots to carry out professional work.

Robot manufacturers are developing interfaces based on generative AI that make it more intuitive for users to program control of robots by using natural language rather than code, and workers will no longer need specialized programming skills to select and adjust robot actions. In addition, predictive AI can save costs by analyzing robot performance data to determine the future state of equipment.

Humanoid robot and taking industrial robots in the automotive manufacturing industry as an example, the cost of unplanned downtime can be as high as $1.3 million per hour, and reducing or even eliminating unplanned downtime through predictive AI technology can provide significant cost savings for enterprises. In addition, machine learning algorithms can analyze data from multiple robots performing the same task and optimize on this basis.

Use subdivision has its own wonderful

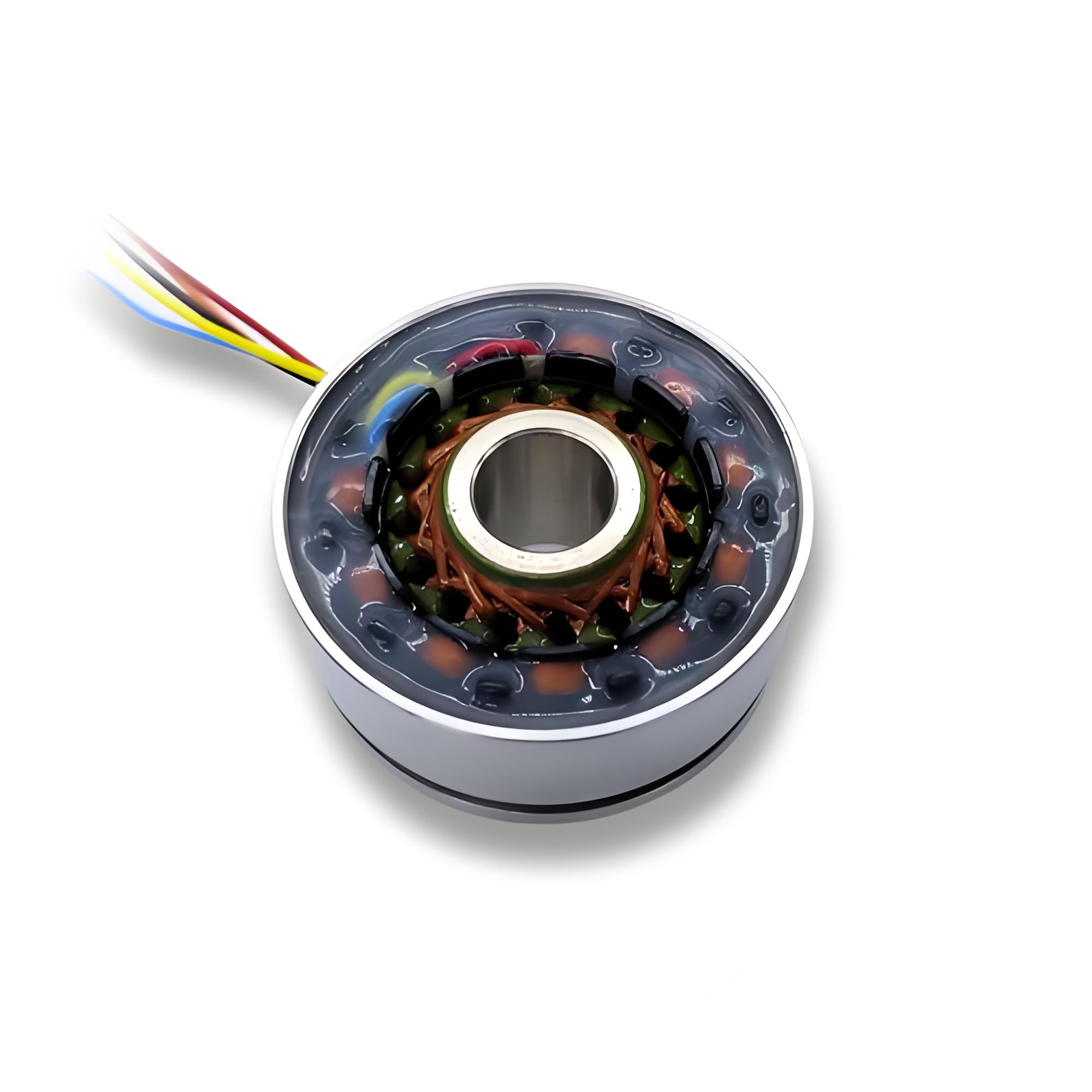

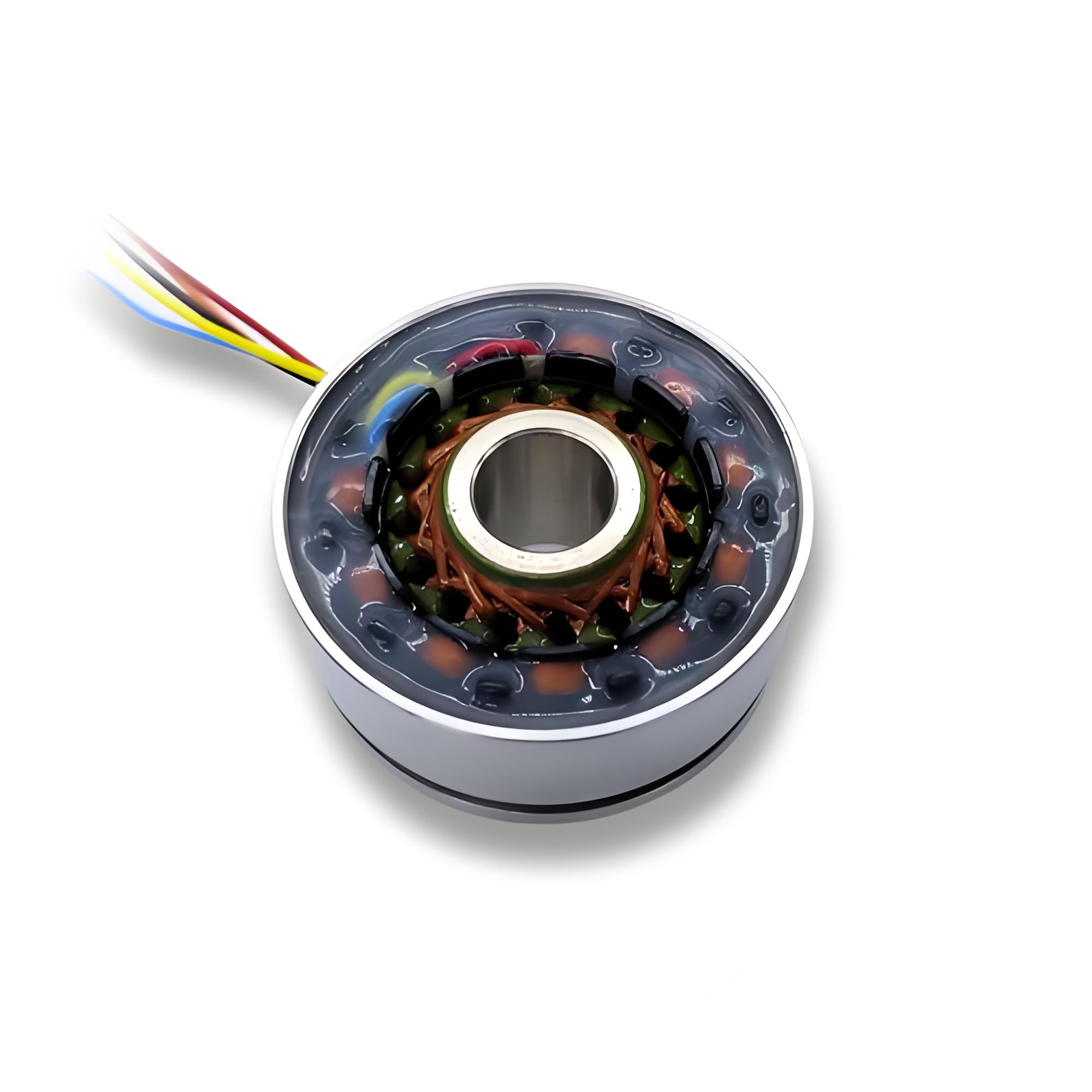

Humanoid robots, as the most intuitive representation of the development of robot technology, have made rapid progress recently, and lifelike and powerful humanoid robots have almost become the standard equipment of various robot technology powers. Humanoid robots use a lot of magnetic components, such as permanent magnet stators, rotors, and sensors resolver, which makes humanoid robots very flexible. The Optimus II humanoid robot, developed by Tesla, can walk, go up and down stairs, squat and take objects. China's "Green Dragon" humanoid robot was unveiled at the World Artificial Intelligence Conference 2024. Its five fingers of steel hand are flexible enough to gently pinch bread without leaving scratches on the bread.

At the same time, although they do not have humanoid, but have super human professional industrial robots, they have also made rapid progress in development and application. Among them, mobile manipulators have great potential in material handling automation, especially in the automotive, logistics and aerospace sectors, which can significantly improve production efficiency. In addition, the application range of collaborative robots is expanding, especially in areas such as welding, which is rapidly filling the demand gap caused by the lack of skilled workers.

Security risks need more attention

With the promotion of robot applications, human-machine coexistence will increasingly become the normal production and life, and the safety problem of robots will undoubtedly be placed in a more prominent position.

In recent years, robot injuries are not uncommon. In 2021, an engineer at Tesla's Texas Gigafactory was writing software programs for two malfunctioning robots when the robot held the engineer down and extended its metal claws toward the engineer's back and arm, leaving an open wound on his left hand.

Science fiction writer Asimov once imagined that the future world is composed of humans and robots, in order to protect humans to make three rules for robots, also known as the "robot three principles", the most important one is that robots must not harm humans. Although the current occurrence of robot injury accidents, can not completely rule out the human operation error, nor can it be determined that the robot has broken the "three principles" began to hurt, but with the increase of human and robot interaction, how to emphasize safety is too much. The principle that robots must not harm human beings is even necessary to upgrade into robots to protect human beings.