A rotary transformer(Resolver Sensors) is an inductive micro-machine whose output voltage maintains a specific functional relationship with the rotor's angular position. It is a displacement sensor that converts angular displacement into electrical signals and serves as a resolver element capable of coordinate transformation and function calculation.

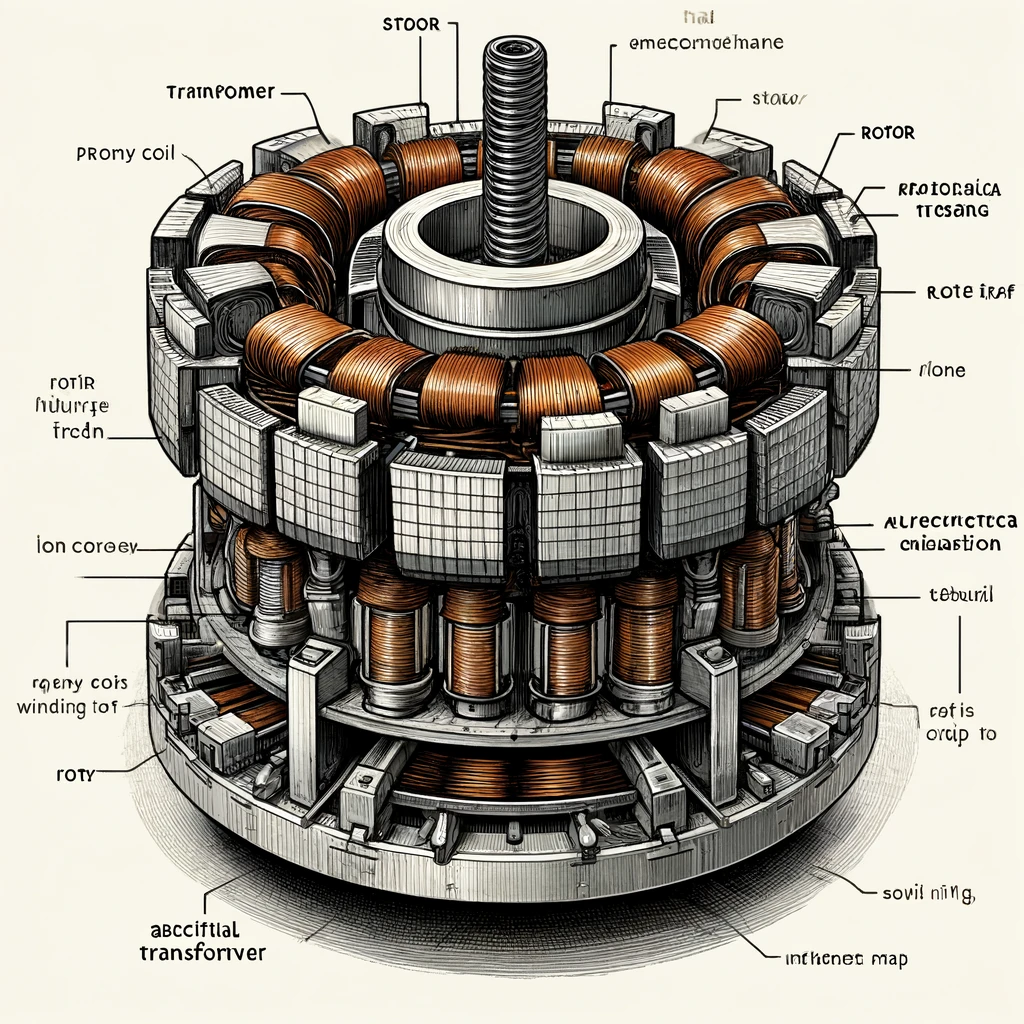

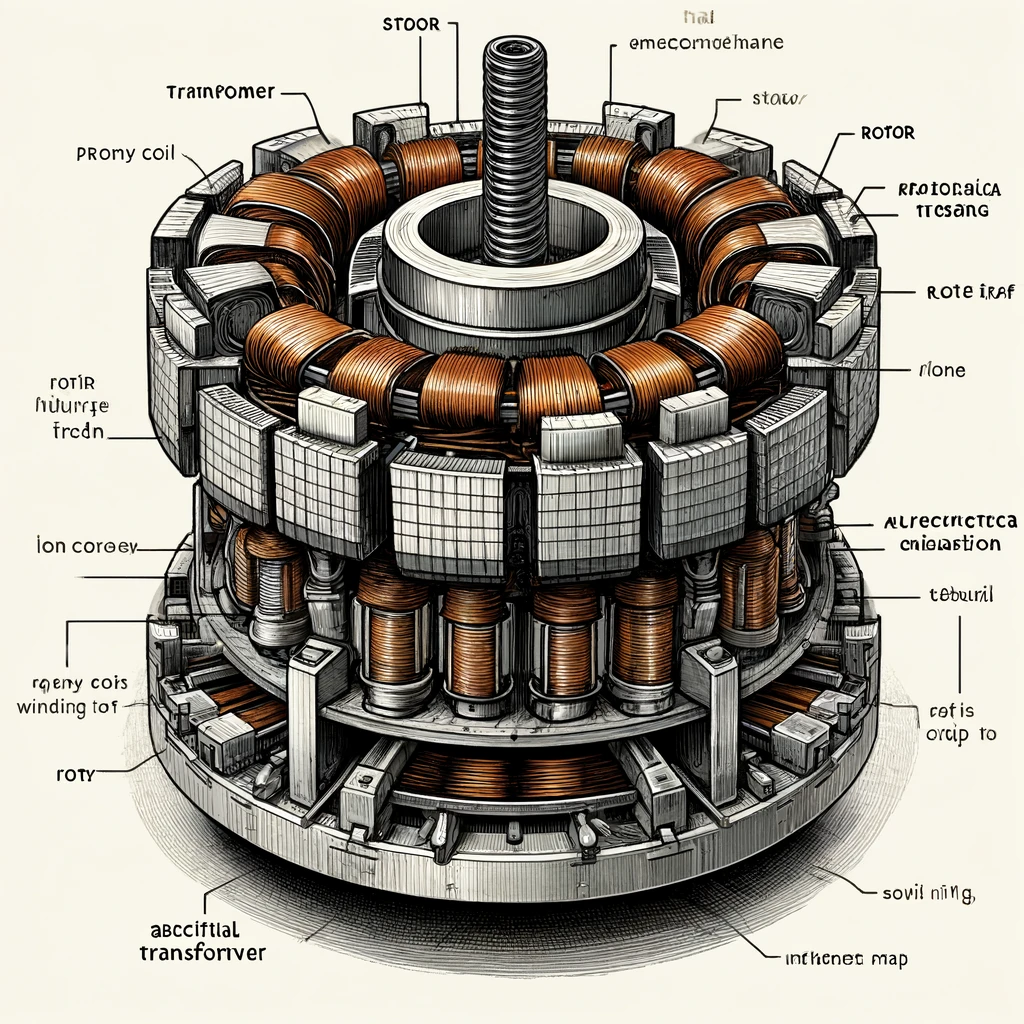

It consists of a stator and a rotor. The stator winding acts as the primary side of the transformer, receiving excitation voltage, while the rotor winding acts as the secondary side, obtaining induced voltage through electromagnetic coupling. The term "rotary transformer" is currently used professionally in China and is abbreviated as "rotary transformer." Some refer to it as a "resolver" or "decomposer."

Rotary transformers are used in motion servo control systems for angle position sensing and measurement. Early rotary transformers were used in computing and solving devices as a main component of analog computers. Their output is an electrical signal that varies with the rotor's angular position in a certain function, typically sinusoidal, cosine, or linear. These functions are common and easy to implement. With specialized design of the windings, it is also possible to produce electrical outputs of certain special functions, but these functions are only used in special occasions and are not general.

With the development of the electronics industry, the integration of electronic components has increased, and the prices of components have significantly decreased. Additionally, advancements in signal processing technology have made the signal processing circuits of rotary transformers simpler, more reliable, and cheaper. Moreover, the emergence of software decoding for signal processing has made the issue of signal processing more flexible and convenient. As a result, the application of rotary transformers has expanded, and their advantages have been more fully realized.

**Working Principle of the Rotary Transformer**

The essence of a rotary transformer is a transformer. Key parameters are similar to transformers, such as rated voltage, rated frequency, and transformation ratio. The difference is that its primary side and secondary side are not fixed but have relative movement. As the relative angle between the two changes, a waveform with varying amplitude can be obtained on the output side. The design of the rotary transformer is based on the above principle: the output signal amplitude varies with position, but the frequency remains unchanged. In practical applications, two sets of output coils are set, with a 90-degree phase difference, resulting in two sets of signals with SIN and COS amplitude variations.

A single-channel angle measurement system can be composed of two identical sinusoidal and cosine rotary transformers. One rotary transformer acts as a transmitter, and the other as a control transformer. The transmitter is excited by an AC power source. The accuracy of the rotary transformer is 6', and the accuracy of the single-channel system is not less than 6'. To improve the control accuracy of the system, a dual-channel angle measurement system can be used.

**Types of Rotary Transformers**

Rotary transformers generally have a structure similar to a wound-rotor motor. Different types or names of rotary transformers can be obtained based on different classification criteria.

- Based on the difference in usage, they can be divided into computing rotary transformers and data transmission rotary transformers.

- Based on the function relationship between output voltage and rotor angle, they can be divided into sinusoidal rotary transformers, linear rotary transformers, and proportional rotary transformers.

- Based on the relative position relationship and specific roles in the angle calculation or related conversion and signal transmission systems constructed by them, they can be divided into rotary transformer transmitters, rotary transformer differential transmitters, and rotary transformer transformers.

Additionally, rotary transformers can be divided into contact and non-contact types (with or without slip ring brush structures); limited angle and unlimited angle types based on rotor rotation angle limits; and single-pole pair and multi-pole pair rotary transformers based on the difference in the number of pole pairs.

**Structure of the Rotary Transformer**

**Brushed Rotary Transformer:** The rotor winding is directly led out through slip rings and brushes. It is characterized by a simple structure and small size, but the reliability is poor, and the lifespan is short due to the mechanical sliding contact between the brushes and slip rings. Currently, this structural form of rotary transformer is rarely used, and the focus is on brushless rotary transformers.

**Brushless Rotary Transformer:** It is divided into two main parts, namely the rotary transformer body and the additional transformer. The primary and secondary iron cores and coils of the additional transformer are annular and fixed on the rotor shaft and housing, respectively, with a certain radial gap.

The rotor winding of the rotary transformer body is connected with the primary coil of the additional transformer. The electrical signal in the primary coil of the additional transformer, i.e., the electrical signal in the rotor winding, is indirectly sent out through the electromagnetic coupling and the secondary coil of the additional transformer.

This structure avoids the adverse effects caused by poor contact between the brushes and slip rings, improving the reliability and service life of the rotary transformer, but its size, weight, and cost are increased. Currently, brushless rotary transformers have two structural forms. One is called the annular transformer type brushless rotary transformer, and the other is called the reluctance rotary transformer.

**Annular Transformer Type Rotary Transformer:** This structure achieves brushless, non-contact well. The right part in the figure is a typical rotary transformer stator and rotor, with the same stator and rotor windings as a brushed rotary transformer for signal conversion. The left part is the annular transformer. Its one winding is on the stator, and the other is on the rotor, placed concentrically.

The annular transformer winding on the rotor is connected with the rotor winding for signal conversion, and the input and output of its electrical signal are completed by the annular transformer.

**Reluctance Rotary Transformer:** The excitation winding and output winding of the reluctance rotary transformer are placed in the same set of stator slots and remain fixed. However, the forms of the excitation winding and output winding are different. The output signal of the two-phase winding should still be an electrical signal that varies sinusoidally with the angle and has a 90° electrical angle difference.

The shape of the rotor magnetic pole is specially designed to make the air gap magnetic field approximately sinusoidal. The design of the rotor shape must also meet the required number of poles. It can be seen that the shape of the rotor determines the number of pole pairs and the shape of the air gap magnetic field. Reluctance rotary transformers are generally made in a split form and not combined together, provided to the user in a split form, assembled by the user.